Fiber-based humidity sensor based on moisture absorption variable resistor and preparation method of fiber-based humidity sensor

A humidity sensor, fiber-based technology, applied in the fields of fiber chemical characteristics, conductive/antistatic filament manufacturing, instruments, etc., can solve the problems of high equipment requirements, increased production process and cost, limited application scope, etc., to achieve good mechanics The effect of performance, excellent hydrophilicity and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a fiber-based humidity sensor based on a hygroscopic rheostat, comprising the following steps:

[0030] S1. After mixing the hydrophilic polymer and water according to the preset mass ratio, then add a predetermined amount of conductive substance and crosslinking agent, and obtain the spinning solution after fully reacting;

[0031] S2. Perform wet spinning on the spinning solution obtained in step S1 to obtain superhydrophilic fibers;

[0032] S3, processing the super-hydrophilic fiber obtained in step S2 into a fabric to obtain a fiber-based humidity sensor based on a hygroscopic rheostat.

[0033] In step S1, the preset mass ratio of the hydrophilic polymer to water is (10-30):(90-70); the mass of the conductive substance accounts for 3%-30% of the mass of the hydrophilic polymer %; the added amount of the cross-linking agent accounts for 0.01% to 0.5% of the mass of the spinning solution; the cross-linking agent is a po...

Embodiment 1

[0039] This embodiment provides a method for preparing a fiber-based humidity sensor based on a hygroscopic rheostat, comprising the following steps:

[0040] S1. After mixing polyvinyl alcohol and water according to the mass ratio of 20:80, carbon tubes and glutaraldehyde are added to obtain a spinning solution after fully reacting; wherein, the mass of carbon tubes accounts for 10% of the mass of polyvinyl alcohol, and the mass of glutaraldehyde is The added amount of dialdehyde was 0.06%.

[0041]S2, extrude the spinning solution obtained in step S1 into a sodium sulfate coagulation bath for wet spinning, and control the speed of the extrusion process to be 30m / min, the speed of drafting to be 300m / min, and the draft ratio It is 10:1, and the super-hydrophilic fiber with a circular cross section is obtained, and its actual figure is as follows figure 1 shown.

[0042] S3, processing the super-hydrophilic fiber obtained in step S2 into a fabric to obtain a fiber-based humi...

Embodiment 2~5

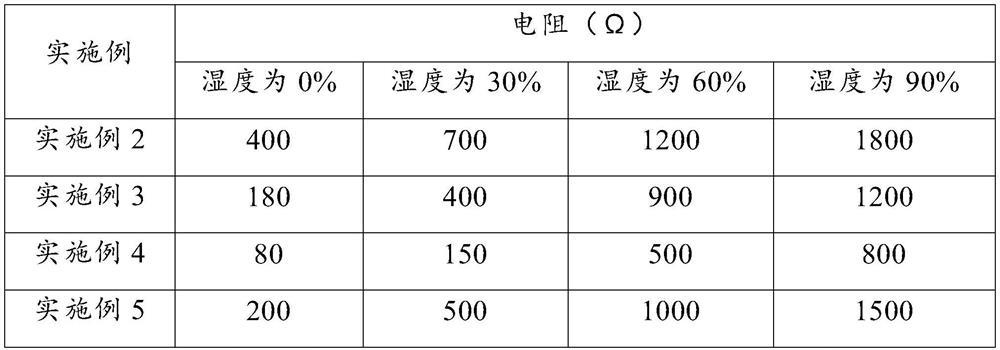

[0048] Embodiments 2 to 5 respectively provide a method for preparing a fiber-based humidity sensor based on hygroscopic rheostats. Compared with Embodiment 1, the difference is that the drafting ratio in step S2 is changed. Embodiments 2 to 5 The draft ratios were 1:1, 5:1, 15:1 and 20:1, respectively. The remaining steps of Embodiments 2-5 are consistent with Embodiment 1, and will not be repeated here.

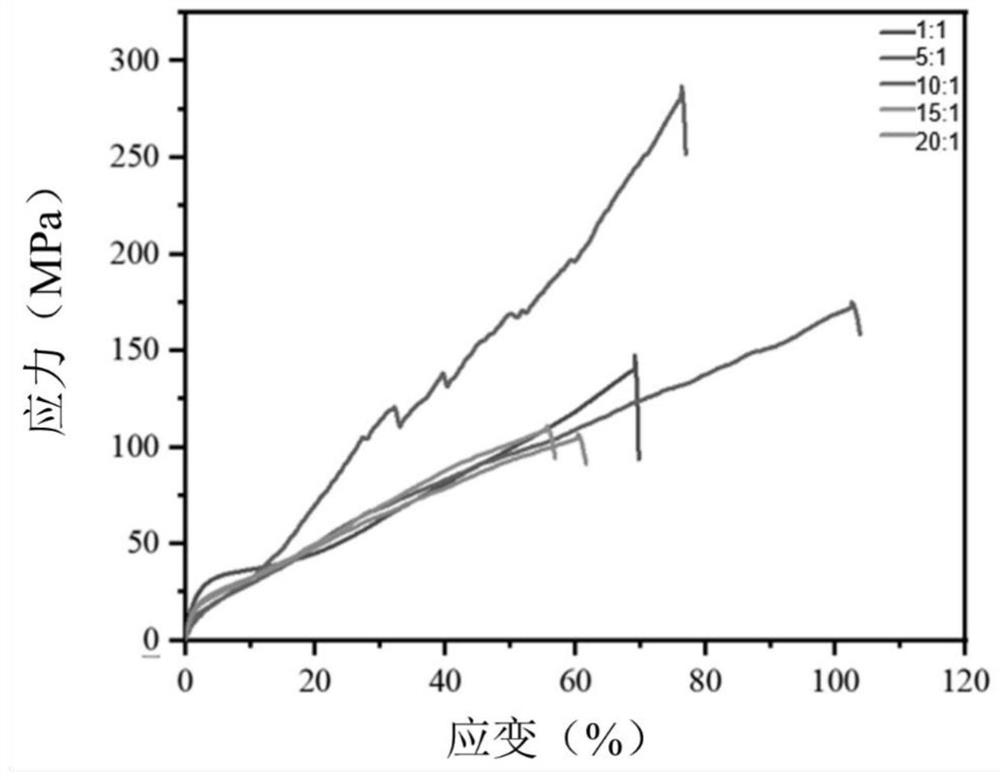

[0049] The mechanical properties of the fiber-based humidity sensor based on hygroscopic varistors prepared in Examples 1 to 5 were tested, and the results were as follows: figure 2 shown. Depend on figure 2 It can be seen that when the draft ratio is increased from 1:1 to 5:1, the strength and toughness of the prepared fibers are significantly improved; when the draft ratio is further increased to 10:1, the fiber toughness continues to increase, but the strength On the contrary, it decreased; after that, the draft ratio continued to increase, and the strength and toug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com