Method for producing metabiotics by carrying out damp-heat quenching on semi-immobilized probiotics

A technology of probiotics and moist heat, applied in the direction of Lactobacillus, bacteria used in food preparation, food science, etc., to achieve the effects of improving immunity, improving intestinal immunity, and fast moisture-based heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

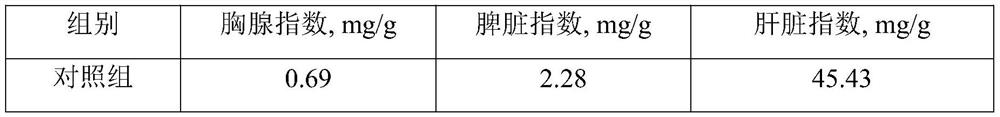

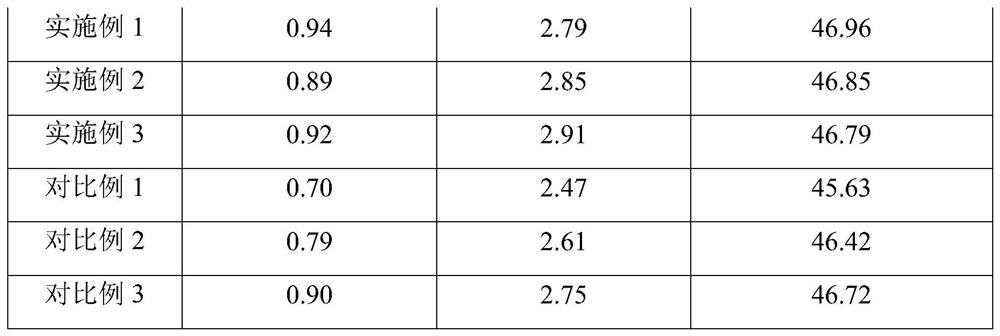

Examples

Embodiment 1

[0029] (1) Preparation of lactic acid bacteria fermentation broth: after activating and purifying the lactic acid bacteria strains, culture them in MRS medium to obtain lactic acid bacteria fermentation broth.

[0030] (2) Centrifugal concentration of fermented liquid: the lactic acid bacteria fermented liquid is centrifuged and concentrated in a disc centrifuge until the concentration of the bacterial liquid is 1×10 11 cfu / g to obtain the lactic acid bacteria concentrate.

[0031] (3) Adsorption and immobilization of lactic acid bacteria: the concentrated solution of lactic acid bacteria and soybean fiber powder were mixed according to the ratio of 2:1 to obtain a mixture.

[0032] (4) Steam damp heat quenching activity: The mixture was inactivated at 100° C. for 5 minutes by steam damp heat sterilization.

[0033] (5) Rapid cooling: the inactivated mixture is rapidly cooled by liquid nitrogen and cold air simultaneously, so that the temperature of the mixture rapidly drops ...

Embodiment 2

[0036] (1) Preparation of lactic acid bacteria fermentation broth: after activating and purifying the lactic acid bacteria strains, culture them in MRS medium to obtain lactic acid bacteria fermentation broth.

[0037] (2) Centrifugal concentration of fermented liquid: the lactic acid bacteria fermented liquid is centrifuged and concentrated in a disc centrifuge until the concentration of the bacterial liquid is 1×10 11 cfu / g to obtain the lactic acid bacteria concentrate.

[0038] (3) Adsorption and immobilization of lactic acid bacteria: the concentrated solution of lactic acid bacteria and soybean fiber powder are mixed according to the ratio of 2.5:1 to obtain a mixture.

[0039] (4) Steam damp heat quenching activity: the mixture was inactivated at 100° C. for 10 min by steam damp heat sterilization.

[0040] (5) Rapid cooling: the inactivated mixture is rapidly cooled by means of dry ice and cold wind at the same time, so that the temperature of the mixture rapidly drop...

Embodiment 3

[0043] (1) Preparation of lactic acid bacteria fermentation broth: after activating and purifying the lactic acid bacteria strains, culture them in MRS medium to obtain lactic acid bacteria fermentation broth.

[0044] (2) Centrifugal concentration of fermented liquid: the lactic acid bacteria fermented liquid is centrifuged and concentrated in a disc centrifuge until the concentration of the bacterial liquid is 1×10 11 cfu / g to obtain the lactic acid bacteria concentrate.

[0045] (3) Adsorption and immobilization of lactic acid bacteria: the concentrated solution of lactic acid bacteria and soybean fiber powder are mixed according to the ratio of 2:1.2 to obtain a mixture.

[0046] (4) Steam damp heat quenching activity: The mixture was inactivated at 100° C. for 7.5 minutes by steam damp heat sterilization.

[0047] (5) Rapid cooling: the inactivated mixture is rapidly cooled by means of ice water and cold air simultaneously, so that the temperature of the mixture rapidly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com