Blueberry alcohol-free flavored fermented beverage

A technology for fermented beverages and blueberries, which is applied in the directions of yeast-containing food ingredients, food ingredients as thickeners, bacteria used in food preparation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

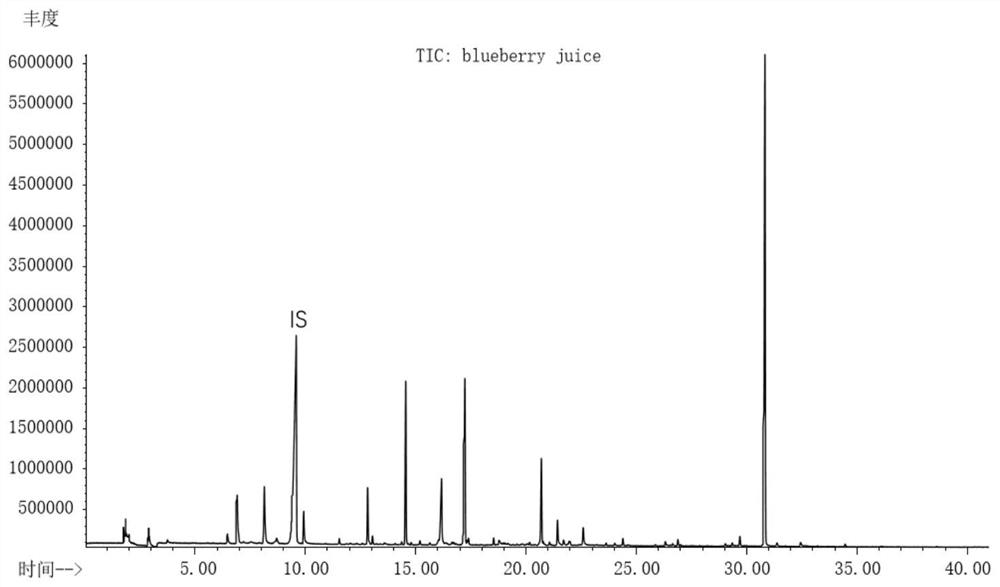

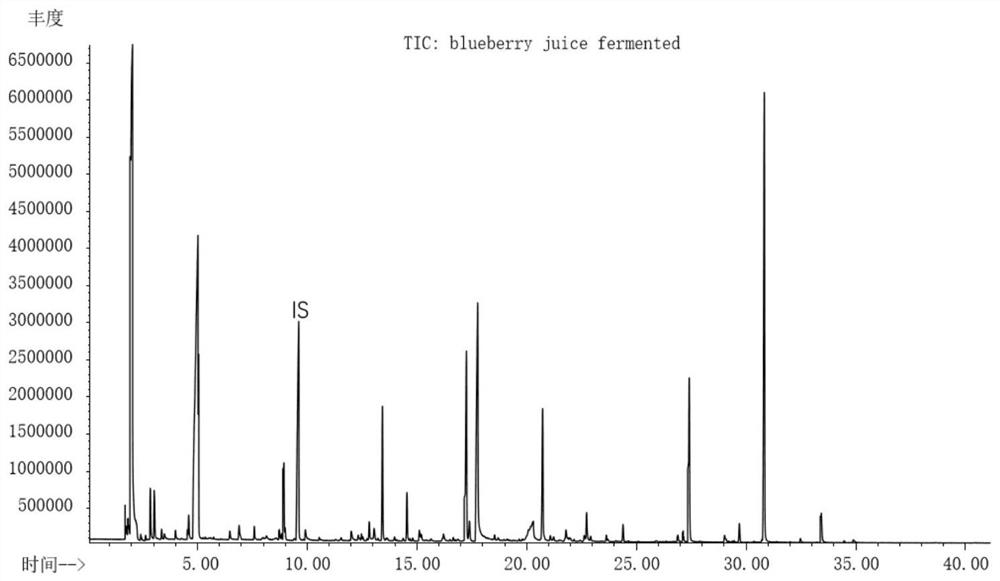

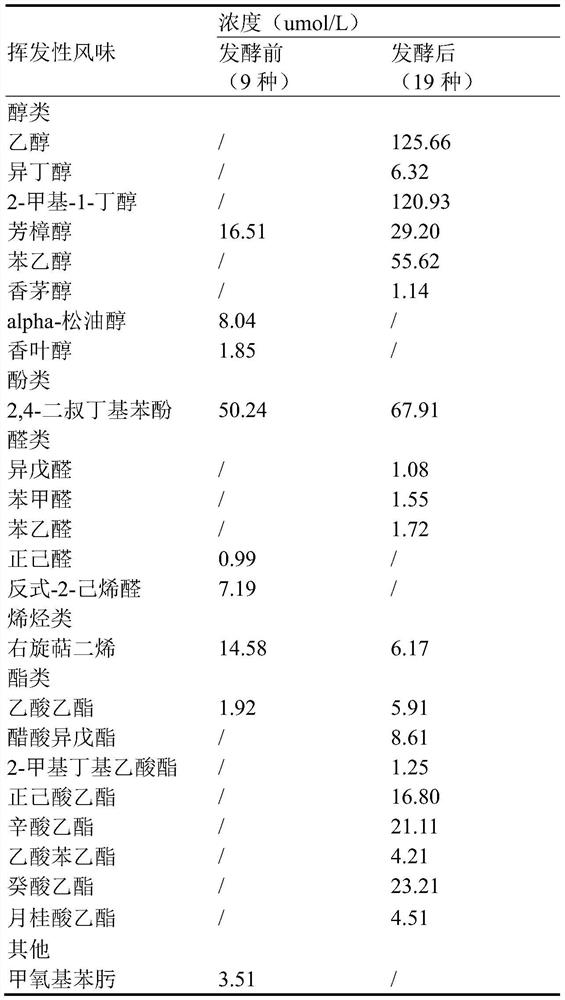

Image

Examples

Embodiment 1

[0030] A kind of blueberry non-alcoholic flavor fermented beverage, its preparation method comprises the following steps:

[0031] S1, fruit selection: select 10 kg of blueberries without mechanical damage and no damage by diseases and insect pests, wash, dry, add 10 kg of pure water, and homogenize with a high-speed homogenizer to obtain blueberry juice;

[0032] S2. Enzymolysis: add 40 g of pectinase and 20 g of cellulase to the blueberry juice in step S1, perform enzymatic hydrolysis at 50°C for 40 minutes, filter with a 100-mesh nylon mesh, remove the blueberry pomace, and obtain a blueberry enzymatic hydrolysis solution;

[0033] S3, color protection: add 2gVE and 200g citric acid to the blueberry enzymatic hydrolysis solution to prevent subsequent processing from destroying blueberry anthocyanins;

[0034] S4, sugar adjustment: the initial sugar content of the blueberry enzymatic hydrolysis filtrate is 7 ° Bx, add white granulated sugar 1.1 kg to the solution in step S3,...

Embodiment 2

[0041] A kind of blueberry non-alcoholic flavor fermented beverage, its preparation method comprises the following steps:

[0042] S1, fruit selection: select 10 kg of blueberries without mechanical damage and no damage by diseases and insect pests, wash, dry, add 10 kg of pure water, and homogenize with a high-speed homogenizer to obtain blueberry juice;

[0043] S2. Enzymolysis: add 40 g of pectinase and 20 g of cellulase to the blueberry juice in step S1, perform enzymatic hydrolysis at 50°C for 40 minutes, filter with a 100-mesh nylon mesh, remove the blueberry pomace, and obtain a blueberry enzymatic hydrolysis solution;

[0044] S3, color protection: add 2gVE and 200g citric acid to the blueberry enzymatic hydrolysis solution to prevent subsequent processing from destroying blueberry anthocyanins;

[0045] S4, sugar adjustment: the initial sugar content of the blueberry enzymatic hydrolysis filtrate is 7°Bx, add fructose syrup 1.1kg to the solution in step S3, adjust the...

Embodiment 3

[0052] A kind of blueberry non-alcoholic flavor fermented beverage, its preparation method comprises the following steps:

[0053] S1, fruit selection: select 10 kg of blueberries without mechanical damage and no damage by diseases and insect pests, wash, dry, add 10 kg of pure water, and homogenize with a high-speed homogenizer to obtain blueberry juice;

[0054] S2. Enzymolysis: add 40 g of pectinase and 20 g of cellulase to the blueberry juice in step S1, perform enzymatic hydrolysis at 50°C for 40 minutes, filter with a 100-mesh nylon mesh, remove the blueberry pomace, and obtain a blueberry enzymatic hydrolysis solution;

[0055] S3, color protection: add 2gVE and 20g citric acid to the blueberry enzymatic hydrolysis solution to prevent subsequent processing from destroying blueberry anthocyanins;

[0056] S4, sugar adjustment: the initial sugar content of the blueberry enzymatic hydrolysis filtrate is 7 ° Bx, add 1.1 kg of sucrose to the solution in step S3, adjust the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com