Foaming mold cleaning adhesive tape without carcinogenic, mutagenic or reproductive toxic components

A reproductive toxicity and mutagenic technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of not clearly avoiding the use of CMR substances, safety, and easy to fly into the air, so as to achieve good mold cleaning effect and increase rubber Effect of internal pressure and easy ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The second aspect of the present invention provides the preparation method of the foam cleaning strip without carcinogenic, mutagenic or reproductive toxic mold cleaning agent as described above, which comprises the following steps:

[0052] (1) Put EPDM rubber and butadiene rubber into the internal mixer and masticate for 2 minutes, then add filler, mold cleaning agent, mold release agent and auxiliary agent and mix for 3 minutes;

[0053] (2) Add foaming agent, curing agent and foaming aid to the above system and mix to 100°C for debinding to obtain the mixed rubber;

[0054] (3) extruding, calendering and cutting the above-mentioned compounded rubber to obtain the mold-cleaning rubber strip.

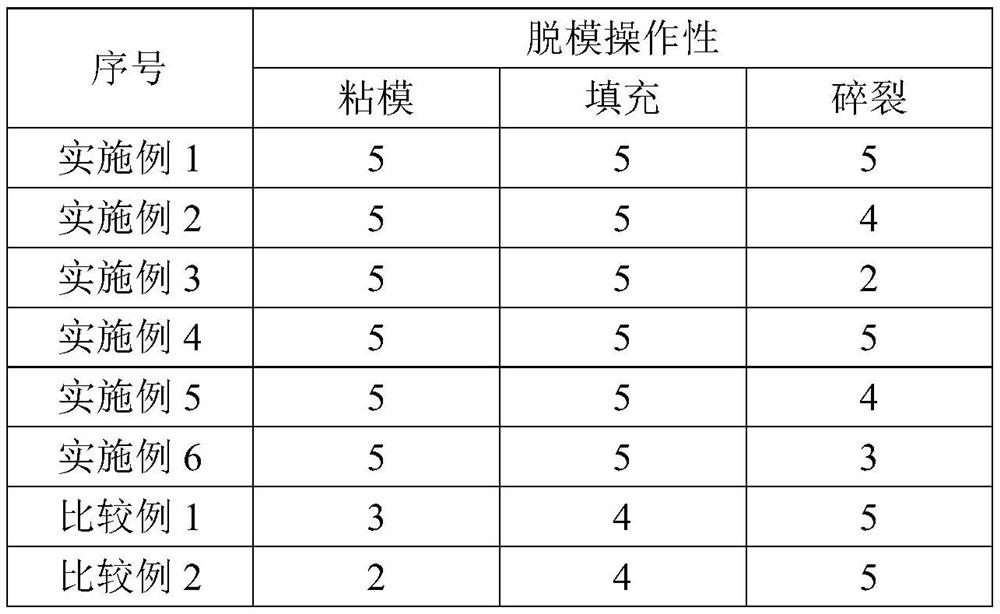

Embodiment

[0056] The present invention is specifically described below by way of examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the content of the present invention above And adjustments still belong to the protection scope of the present invention. The following is the table of examples, which are prepared according to the following method: put the raw rubber into an internal mixer and masticate for 2 minutes, then add fillers, mold clearing agents, mold release agents, and pigments and mix for 3 minutes, and mix foaming agent and vulcanizing agent. Refining to 100°C for debinding to obtain rubber compound. Further extruding, calendering and cutting the compounded rubber to obtain mold-cleaning rubber strips.

[0057] Table 1 embodiment form (ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com