Method for processing tangerine slices for tea making

A processing method and a technology for orange red tablets, which are applied in the field of processing Chinese herbal medicine pieces, can solve the problems of affecting the quality, affecting the quality and use of orange red, and the loss of effective components, and achieving the effect of protecting the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

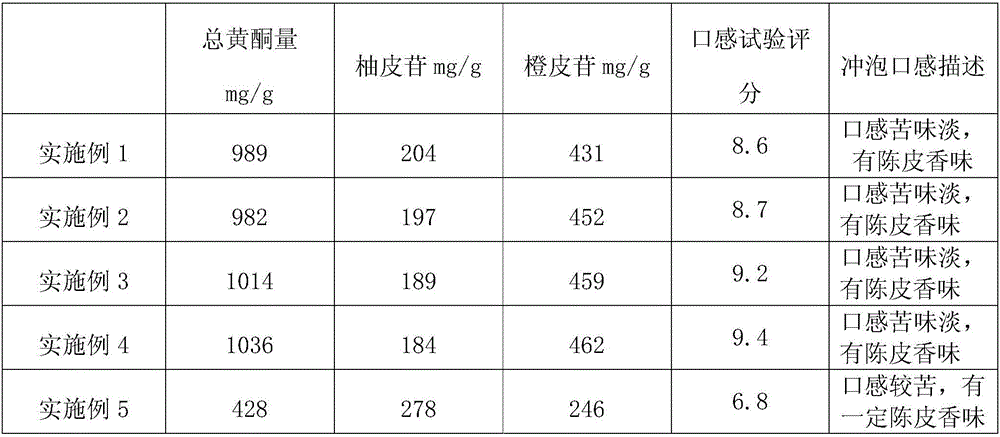

Examples

Embodiment 1

[0033] A processing method for orange-red slices for making tea, comprising the following steps:

[0034] a. Pretreatment and deenzyming: After the picked healthy tangerine fruit is washed with an aqueous acid solution, take it out and put it in an environment with a saturated steam temperature of 100°C for 25 minutes to degreen the tangerine fruit;

[0035] Wherein, the acid aqueous solution is selected from a mixture of citric acid and fumaric acid, and the mixing ratio of citric acid and fumaric acid is 3:1; the mass percent concentration of the acid in the acid aqueous solution is 0.5%.

[0036] b. Slicing: take the green orange red fruit described in step a and cut it into slices with a thickness of 5mm using a slicer under a hot air environment to obtain orange red slices;

[0037] c. Enzymolysis reaction: take the orange-red slices described in step b, first place them in a blast environment at 50°C and dry them to a moisture content of 35%, then evenly spray the enzymo...

Embodiment 2

[0043] A processing method for orange-red slices for making tea, comprising the following steps:

[0044] a. Pretreatment and deenzyming: After the picked healthy tangerine fruit is washed with an aqueous acid solution, take it out and put it in an environment with a saturated steam temperature of 125°C for 5 minutes to degreen the tangerine fruit;

[0045] Wherein, the acid aqueous solution is selected from malic acid; the mass percent concentration of the acid in the acid aqueous solution is 2.0%.

[0046] b. Slicing: take the green orange red fruit described in step a and cut it into slices with a thickness of 2mm using a slicer under a hot air environment to obtain orange red slices;

[0047] c. Enzymolysis reaction: take the orange-red slices described in step b, first place them in a blast environment at 60°C and dry them until the moisture content is 45%, then spray the enzymolysis solution evenly on the surface of the orange-red slices, and then use the conventional pr...

Embodiment 3

[0053] A processing method for orange-red slices for making tea, comprising the following steps:

[0054] a. Pretreatment and de-greening: After the picked healthy tangerine fruit is washed with an aqueous acid solution, it is taken out and placed in an environment with a saturated steam temperature of 105°C for 20 minutes to de-green the tangerine fruit;

[0055] Wherein, the acid aqueous solution is selected from citric acid; the mass percent concentration of the acid in the acid aqueous solution is 1.0%.

[0056] b. Slicing: take the green orange red fruit described in step a and cut it into slices with a thickness of 3mm using a slicer under a hot air environment to obtain orange red slices;

[0057] c. Enzymolysis reaction: take the orange-red slices described in step b, first place them in a blast environment at 53°C and dry them to a moisture content of 38%, then evenly spray the enzymatic hydrolysis solution on the surface of the orange-red slices, and then dry them ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com