Liquid sealing film for injection molding cup and film coated paper cup and preparation method of liquid sealing film

A technology for laminating paper cups and sealing films, which is applied in the field of injection-molded cups and liquid sealing films for laminating paper cups and their preparation. Low, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

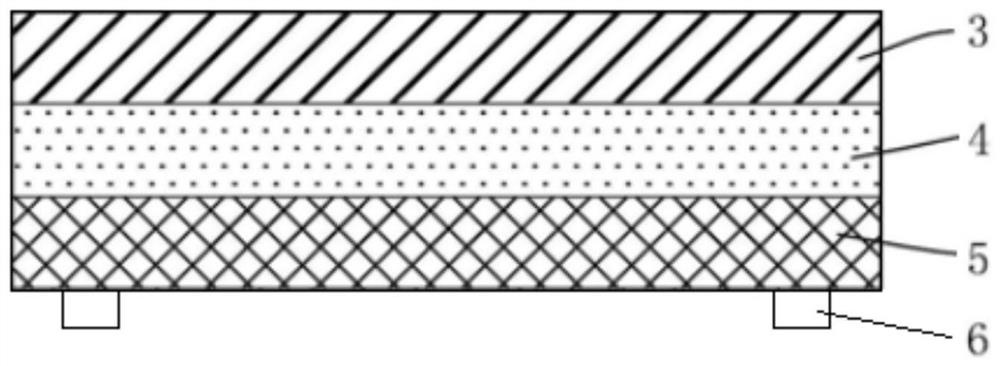

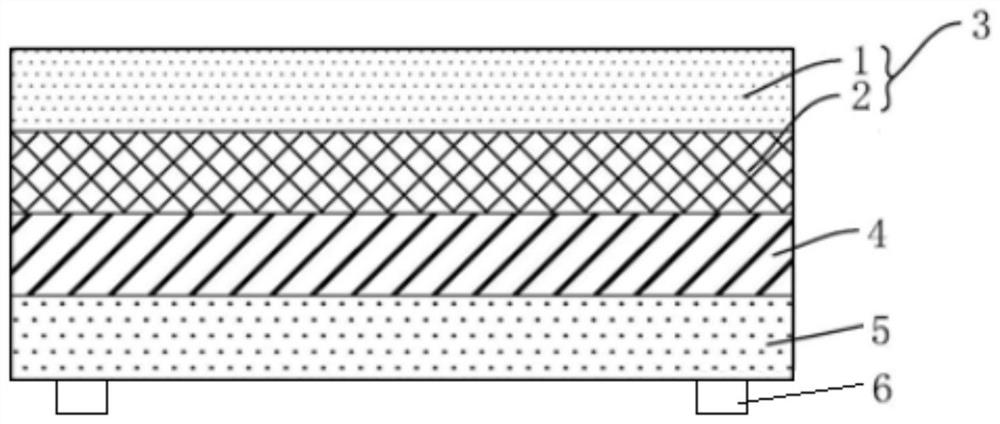

[0034] The preparation method of the injection cup provided by the invention and the liquid sealing film of the coated paper cup comprises the following steps:

[0035] 1) Batching, mixing, and salivating the components of the heat-sealing layer to form a film to obtain the heat-sealing layer 5;

[0036] 2) After corona treatment, the heat-sealing layer 5 and the barrier layer 4 are heat-pressed and compounded and cured;

[0037] 3) Print an oil film on the surface of the semi-permeable super-pressure glassine paper, and perform oil-proof and waterproof treatment after drying to obtain the printing layer 3; or print the ink layer 2 on the surface of the frosted film 1, and obtain the printing layer 3 after drying;

[0038] 4) Compositing and curing the composite film obtained in step 2) and the printing layer 3 by hot pressing to obtain a semi-formed film;

[0039] 5) Use a glue applicator to apply glue on one side of the semi-film-formed heat-sealing layer to form a heat-sea...

Embodiment 1

[0042] The preparation method of injection molding cup and coated paper cup liquid sealing film comprises the following steps:

[0043] 1) By weight: 10 parts of high-density polyethylene, 12 parts of low-density polyethylene, 27 parts of linear low-density polyethylene, 7 parts of ethylene-methacrylic acid copolymer, 10 parts of ethylene-vinyl acetate copolymer, poly Add 15 parts of olefin plastomer to a high-speed mixer for stirring and mixing, and then salivate to form a film to obtain a heat-sealing layer;

[0044] 2) After corona treatment, the heat-sealing layer and the barrier layer (polyamide film) are hot-compressed and cured;

[0045] 3) Print an oil film on the surface of semi-permeable super-pressure glassine paper, and perform oil-proof and waterproof treatment after drying to obtain a printing layer;

[0046] 4) Compositing and curing the composite film obtained in step 2) and the printing layer by hot pressing;

[0047] 5) Slitting and packaging to obtain liquid...

Embodiment 2

[0049] The preparation method of injection molding cup and coated paper cup liquid sealing film comprises the following steps:

[0050] 1) By weight: 12 parts of high-density polyethylene, 8 parts of low-density polyethylene, 25 parts of linear low-density polyethylene, 6 parts of ethylene-methacrylic acid copolymer, 12 parts of ethylene-vinyl acetate copolymer, poly Add 12 parts of olefin plastomer into a high-speed mixer for stirring and mixing, and then salivate to form a film to obtain a heat-sealing layer;

[0051] 2) After corona treatment, the heat-sealing layer and the barrier layer (copolyester PETG film) are hot-compressed and cured;

[0052] 3) Print the ink layer on the surface of the frosted film, and obtain the printing layer after drying;

[0053] 4) Compositing and curing the composite film obtained in step 2) and the printing layer by hot pressing to obtain a semi-formed film;

[0054] 5) Use a glue applicator to coat food-grade hot melt adhesive on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com