Wear-resistant aluminum alloy manufacturing process

A production process and aluminum alloy technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of improving the mechanical strength and wear resistance of aluminum alloys, and achieve improved corrosion resistance, good grain refinement, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A wear-resistant aluminum alloy production process, specifically comprising the following steps:

[0041] Step S1: Add silicon nitride and aluminum alloy powder into the planetary ball mill, control the ball-to-material ratio to 3:1, and mix the silicon nitride and aluminum alloy powder fully under the condition of rotating speed of 200r / min and ball milling time for 2h , to obtain mixed powder;

[0042] Step S2: adding the uniformly mixed mixed powder into the concave mold of the forming mold, and pressing and molding under the condition of a pressure of 590 MPa to obtain an aluminum alloy blank;

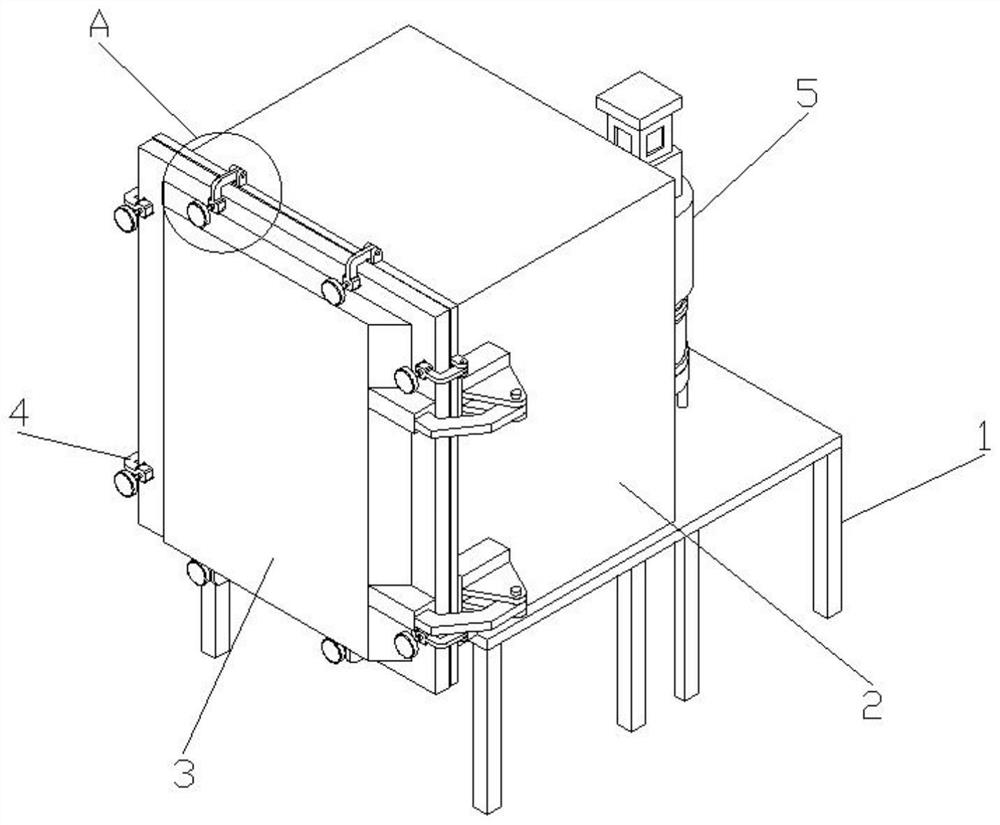

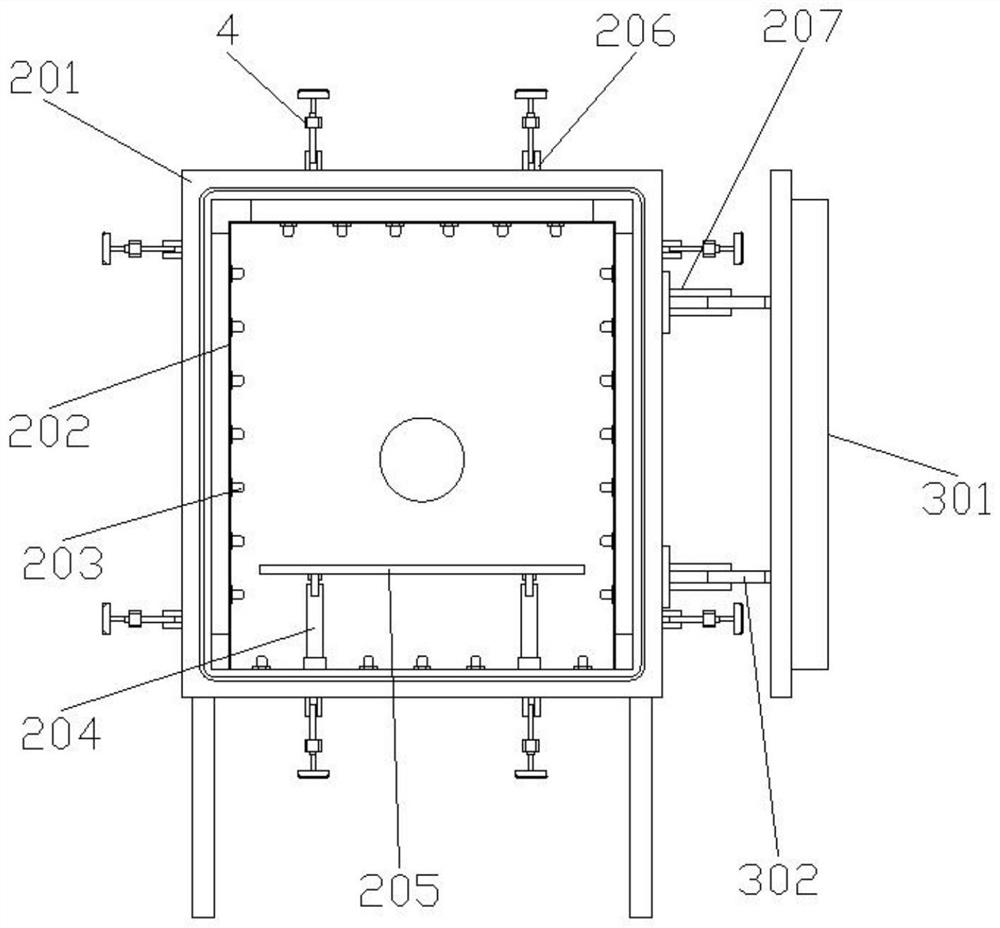

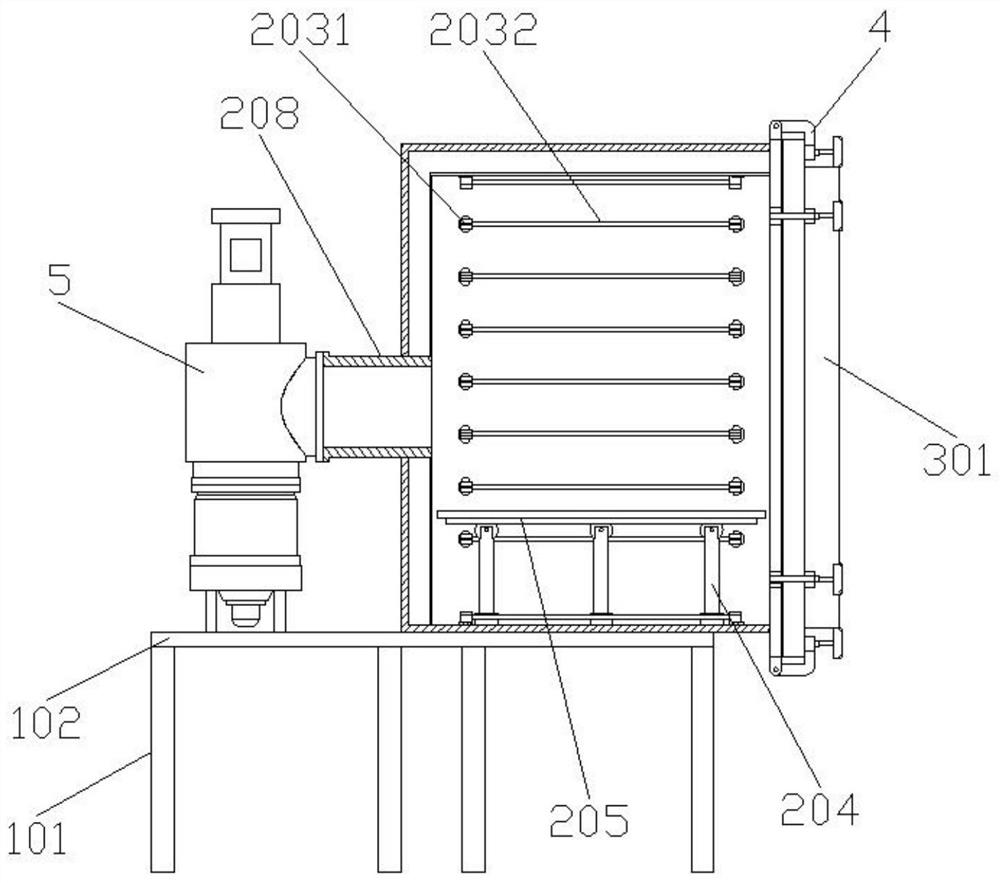

[0043] Step S3: See Figure 1-6 As shown, open the box door body 301 of the vacuum sintering equipment, place the aluminum alloy body evenly on the cross bar 2053 of the supporting plate assembly 205, then push the supporting plate assembly 205 into the sintering box assembly 2, and then close the box door body 301, rotate the L-shaped bracket 401 around the sintering box ...

Embodiment 2

[0053] A wear-resistant aluminum alloy production process, specifically comprising the following steps:

[0054] Step S1: Add silicon nitride and aluminum alloy powder into the planetary ball mill, control the ball-to-material ratio to 3:1, and under the condition of rotating speed of 300r / min, ball milling time is 2.5h, fully mix the silicon nitride and aluminum alloy powder Mix to obtain mixed powder;

[0055] Step S2: adding the uniformly mixed mixed powder into the concave mold of the forming mold, and pressing and molding under the condition of a pressure of 600 MPa to obtain an aluminum alloy blank;

[0056] Step S3: See Figure 1-6 As shown, open the box door body 301 of the vacuum sintering equipment, place the aluminum alloy body evenly on the cross bar 2053 of the supporting plate assembly 205, then push the supporting plate assembly 205 into the sintering box assembly 2, and then close the box door body 301, rotate the L-shaped bracket 401 around the sintering box...

Embodiment 3

[0066] A wear-resistant aluminum alloy production process, specifically comprising the following steps:

[0067] Step S1: Add silicon nitride and aluminum alloy powder into the planetary ball mill, control the ball-to-material ratio to 3:1, and mix the silicon nitride and aluminum alloy powder fully under the condition of rotating speed of 400r / min and ball milling time for 3h , to obtain mixed powder;

[0068] Step S2: adding the uniformly mixed mixed powder into the concave mold of the forming mold, and pressing and molding under the condition of a pressure of 620 MPa to obtain an aluminum alloy blank;

[0069] Step S3: See Figure 1-6 As shown, open the box door body 301 of the vacuum sintering equipment, place the aluminum alloy body evenly on the cross bar 2053 of the supporting plate assembly 205, then push the supporting plate assembly 205 into the sintering box assembly 2, and then close the box door body 301, rotate the L-shaped bracket 401 around the sintering box ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com