A nickel-based superalloy with high structural stability and its preparation method

A nickel-based high-temperature alloy, stability technology, applied in the field of high-temperature alloys, to achieve the effect of less addition, strong structure stability, and maximize high-temperature creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

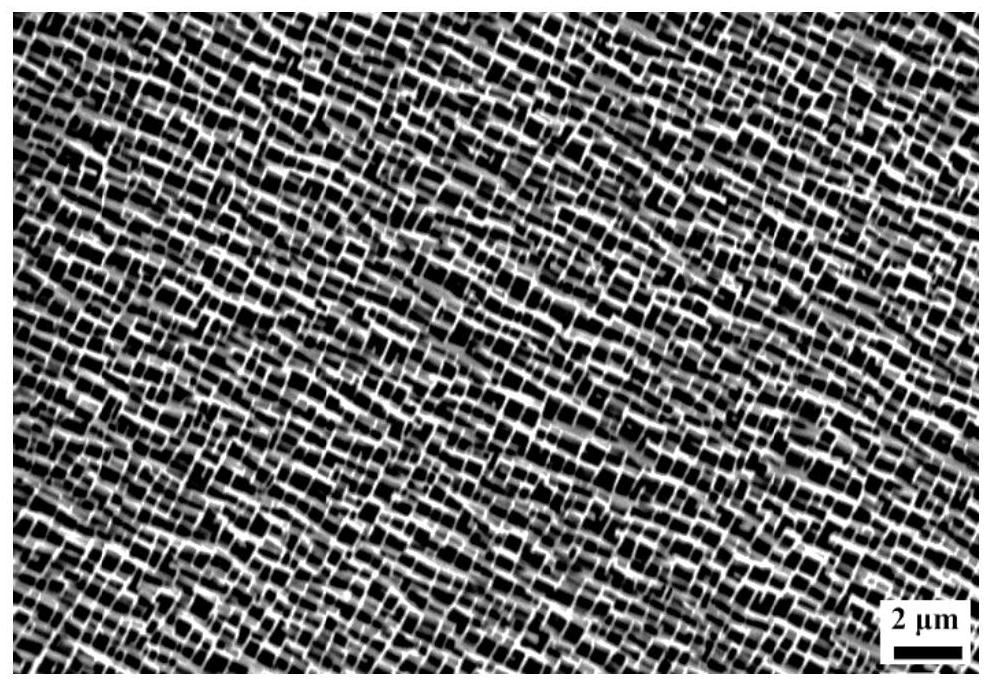

[0039] Alloy compositions shown in Table 1 according to a scale of high purity Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W and other elemental metal, the metal material described above was weighed placed in a vacuum arc melting furnace, carried out in high purity alloy melting in an argon atmosphere, melting in the arc current magnitude control 350A, until the alloy is completely liquefied held for 1 minute, and then cooled off to the alloy is completely solidified. In the high purity argon gas atmosphere, the lower nickel-based superalloy ingot prepared in the above solution temperature of 1320 ℃; 12 times repeating the melting step, to ensure uniformity of the alloy, to give a final nickel-base superalloy ingots for 24 h, cooled, and then incubated for 4h at 1150 ℃, air-cooled, and then incubated 24h at 870 deg.] C, cooled to give a nickel-based superalloy of high structural stability. like figure 1 , A typical morphology of the alloy in Example 1 is a scanning electron micrograph embodim...

Embodiment 2

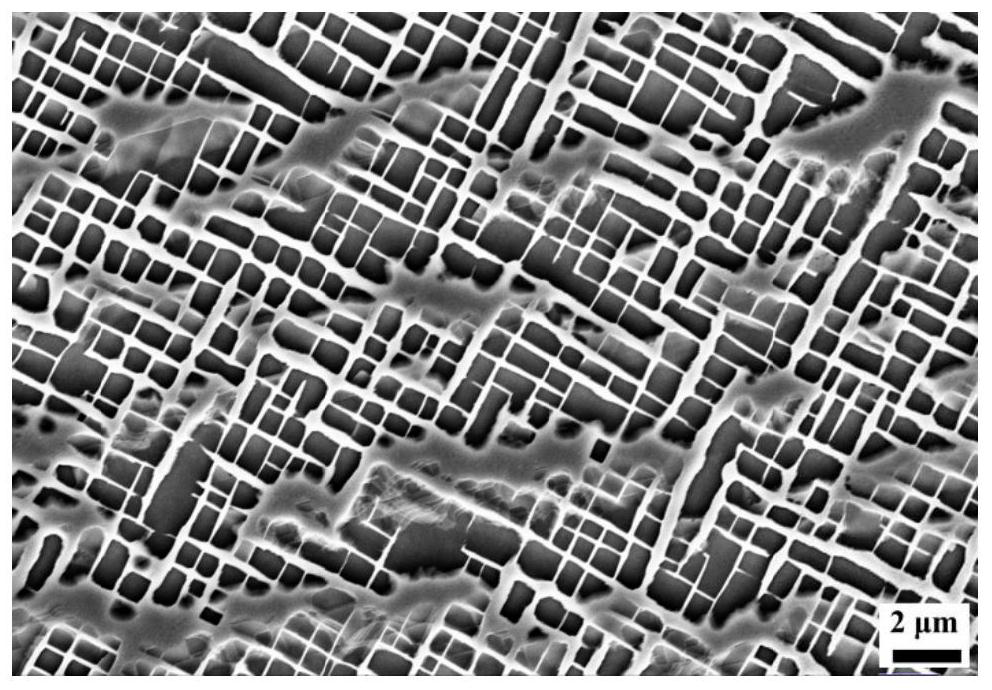

[0041] Table 1 Alloy composition according weighed 2 high purity Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W and other elemental metal, the metal material described above was weighed placed in a vacuum arc melting furnace, carried out in high purity alloy melting in an argon atmosphere, melting in the arc current magnitude control 350A, until the alloy is completely liquefied held for 1 minute, and then cooled off to the alloy is completely solidified. In the high purity argon gas atmosphere, the lower nickel-based superalloy ingot prepared in the above solution temperature of 1330 ℃; 12 times repeating the melting step, to ensure uniformity of the alloy, to give a final nickel-base superalloy ingots incubated for 10 hours and cooled, followed by incubation for 4h at 1100 ℃, air-cooled, and then incubated 16h at 870 deg.] C, cooled to give a nickel-based superalloy of high structural stability. like Figure 4 , A typical morphology of Example 2 of the alloy of the present invention is a scan...

Embodiment 3

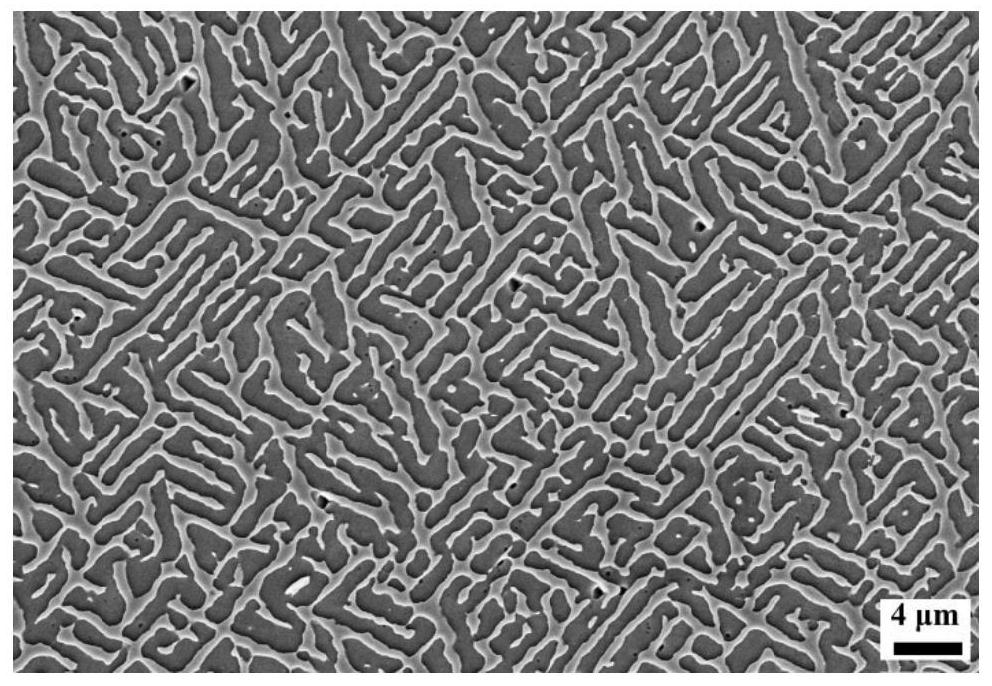

[0043] Table 1 Alloy composition according to the high purity weighed 3 Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W and other elemental metal, the metal material described above was weighed placed in a vacuum arc melting furnace, carried out in high purity alloy melting in an argon atmosphere, melting in the arc current magnitude control 350A, until the alloy is completely liquefied held for 1 minute, and then cooled off to the alloy is completely solidified. In the high purity argon gas atmosphere, the lower nickel-based superalloy ingot prepared in the above solution temperature of 1330 ℃; 10 times repeating the melting step, to ensure uniformity of the alloy, to give a final nickel-base superalloy ingots incubated for 16 hours and cooled, followed by incubation for 4h at 1150 ℃, air-cooled, and then incubated 23h at 870 deg.] C, cooled to give a nickel-based superalloy of high structural stability. like Image 6 Typical morphology of the SEM image, gamma] Example 3 Alloy embodiment shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com