Raw material processing device for vinegar processing

A technology for processing raw materials and processing devices, which is used in the preliminary treatment of promoting the drying of solid materials, drying solid materials and biofuels without heating, etc. , the effect of speeding up the dehydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

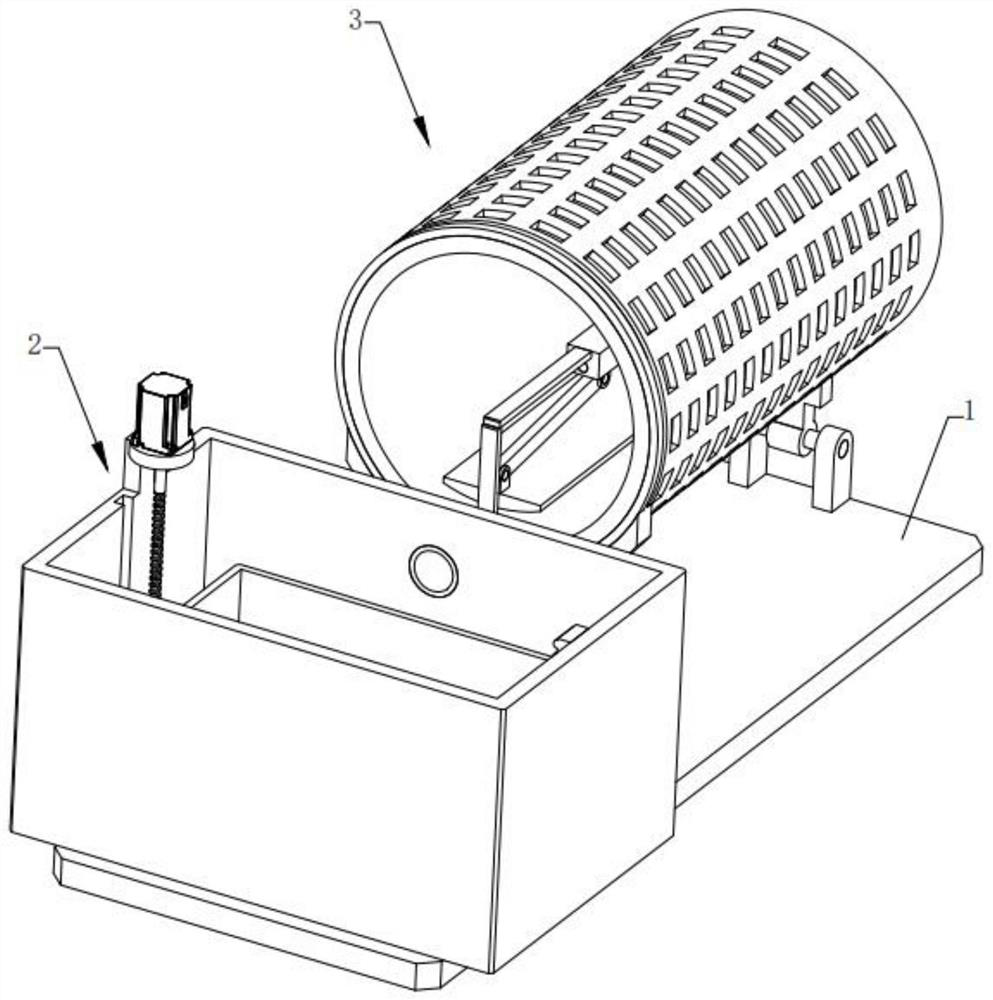

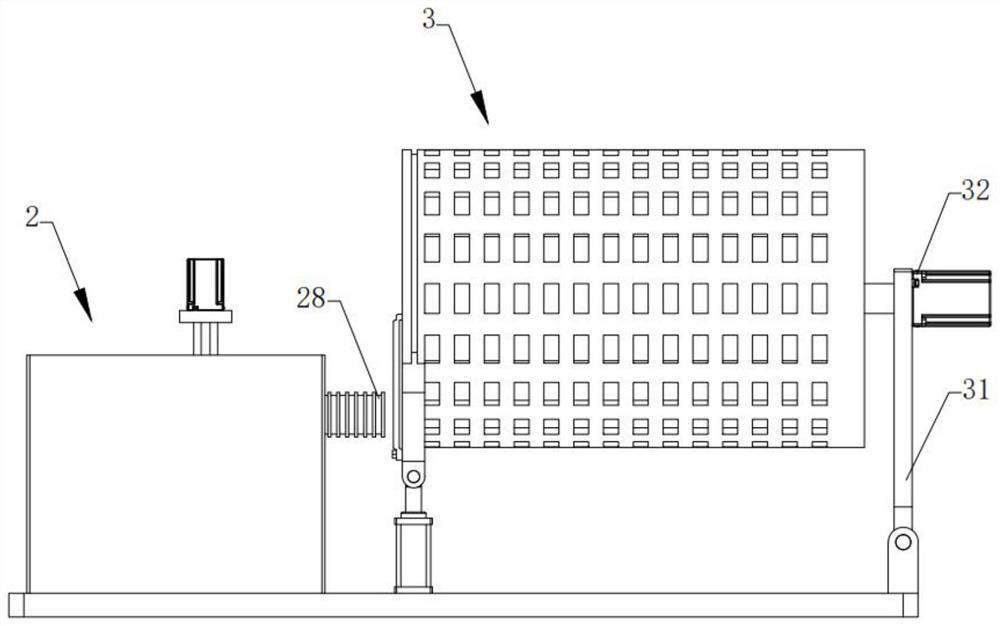

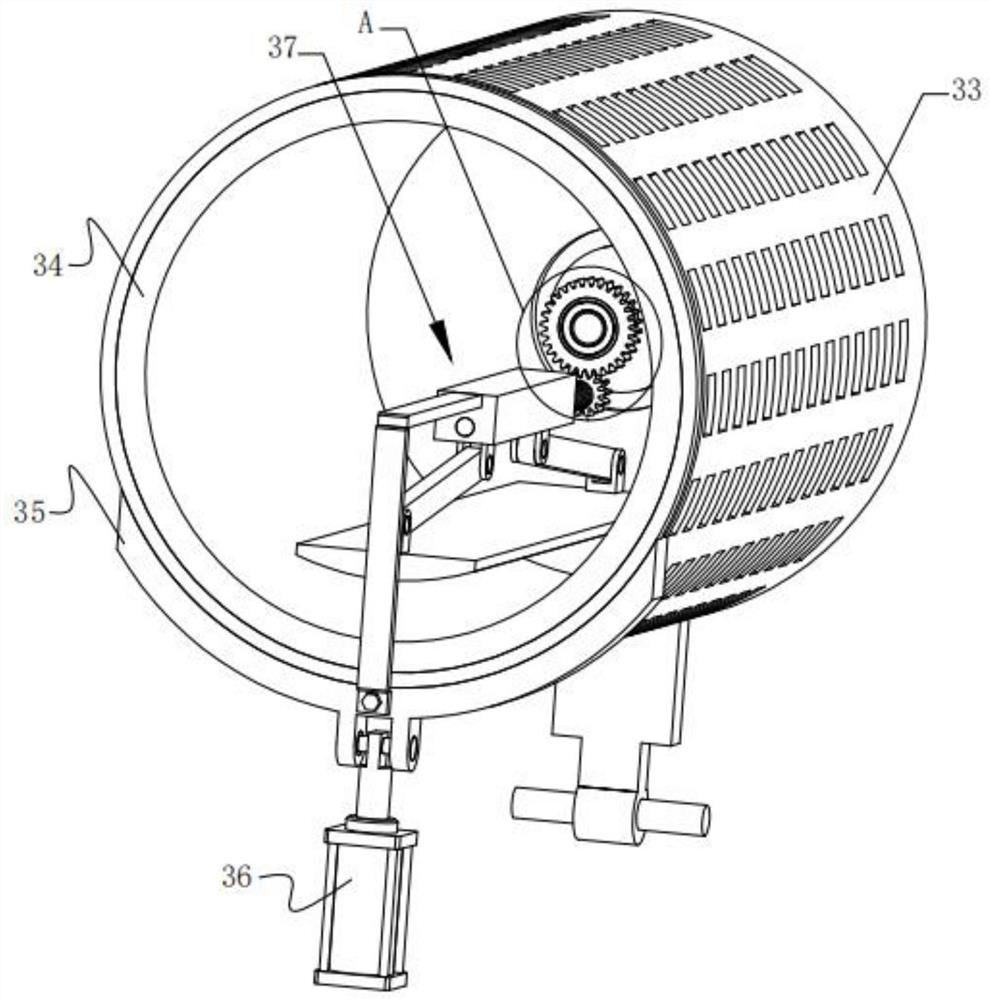

[0025] see Figure 1 to Figure 7 , the present invention provides a kind of technical scheme:

[0026] A raw material processing device for vinegar processing, comprising a rack 1, a soaking mechanism 2 and a dehydration mechanism 3, wherein:

[0027] The soaking mechanism 2 is arranged on the frame 1, and the soaking mechanism 2 includes a water tank 21, a soaking tank 22, a connecting plate 23, a spring 24, a linear drive mechanism 25, a baffle 26, a top rod 27 and a telescopic hose 28, and the water tank 21 is arranged in the On the frame 1, the connecting plate 23 is arranged in the guide groove on the inner wall of the water tank 21, and forms a moving pair in the guide groove on the inner wall of the water tank 21, and the soaking tank 22 is connected with the connecting plate 23 through the spring 24, wherein the two ends of the spring 24 They are fixedly connected to the side wall of the soaking box 22 and the connecting plate 23 respectively. The bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com