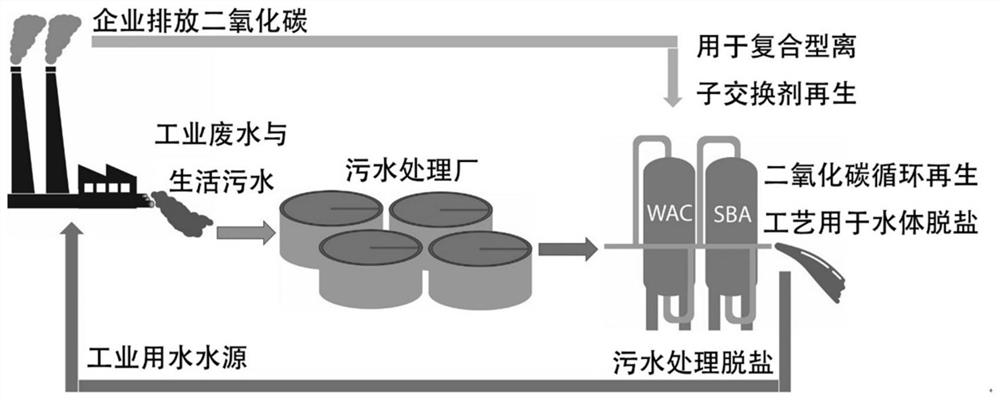

Circulating carbon dioxide regeneration ion exchange system and process for simultaneously realizing water body purification and carbon emission reduction

A carbon dioxide and water purification technology, applied in the field of water treatment, can solve the problems of low water production rate, low efficiency, long regeneration time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

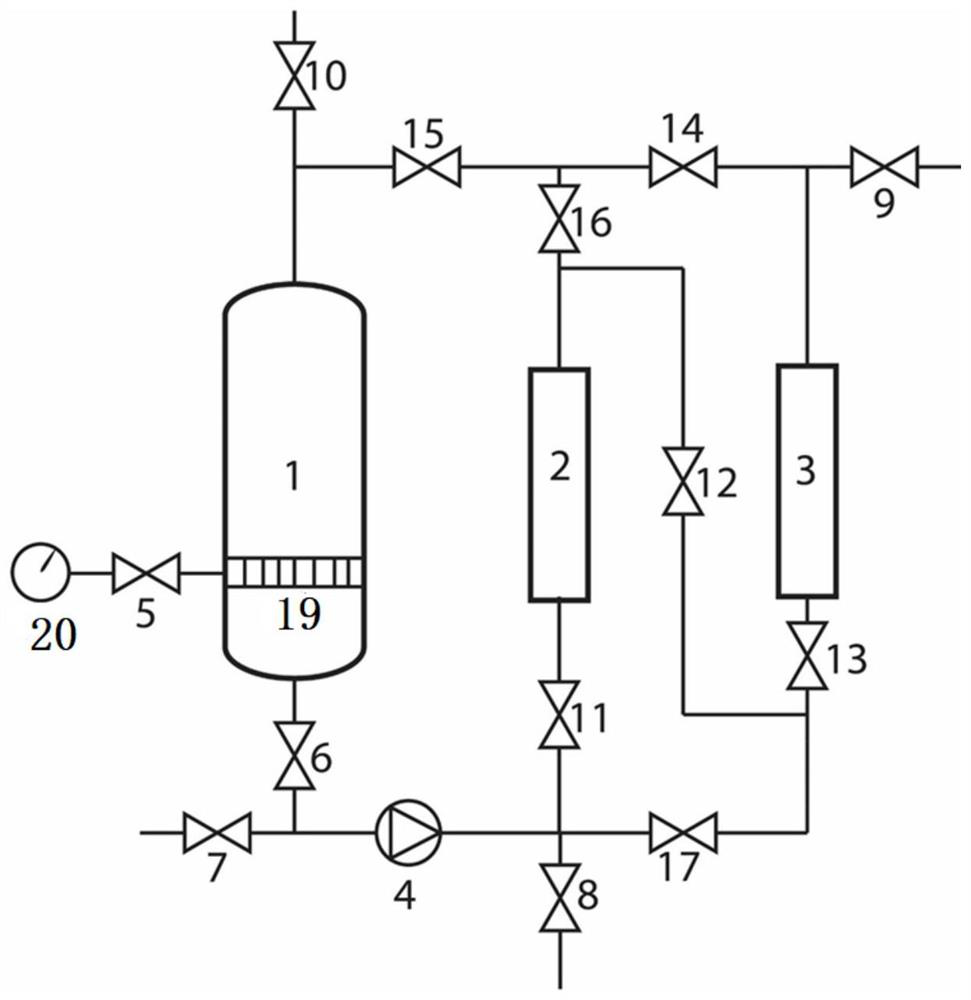

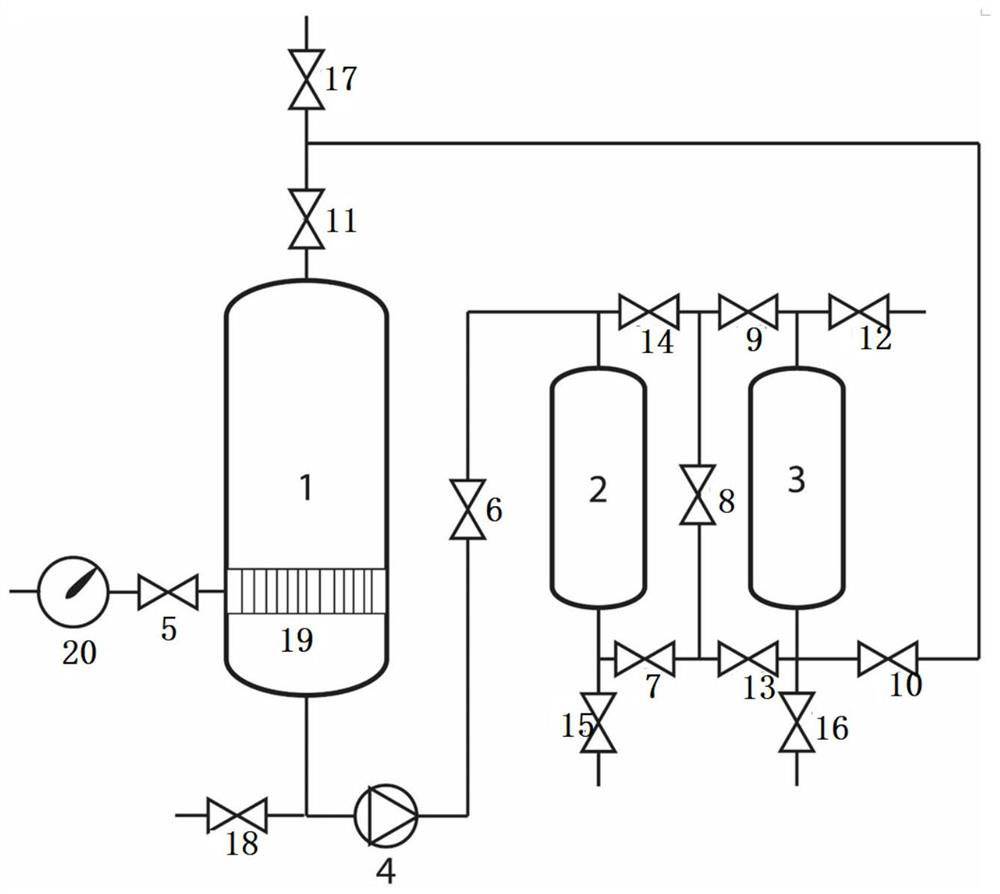

Method used

Image

Examples

Embodiment 1

[0106] Use latent shell weakly acidic cationic resin ( Figure 4 ) and type I strongly basic anion exchange resin ( Figure 5 ) combination, used to remove chloride ions in actual sewage plants for circulating cooling water in thermal power plants (chloride ion concentration requirement 150mg / L). Through water production comparison, the internal circulation regeneration system can provide qualified water for more than 90 beds. However, in the prior art, the chloride ion concentration of the initial product water passing through the system at one time has exceeded 150, which cannot produce qualified water.

Embodiment 2

[0108] A combination of weakly acidic polymethacrylic acid cationic resin and type II strong basic anion resin is used to remove sulfate radicals in tap water. Among them, the sulfate radical regeneration efficiency of the once-through system is only 5%, while the sulfate radical regeneration efficiency provided by the internal circulation regeneration process is 30%.

Embodiment 3

[0110] Use latent shell weakly acidic cation resin and type I strong basic anion resin combination to remove excessive hardness and sulfate radicals in water. Among them, the sulfate radical regeneration efficiency of the once-through system is only 7%, while the sulfate radical regeneration efficiency provided by the internal circulation regeneration system under the same pressure is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com