Concrete with cracking resistance and freezing resistance

A technology of concrete and frost resistance, applied in the field of concrete, can solve the problems of steel surface corrosion, passivation film damage, concrete cracking, etc., to achieve good frost resistance, high anti-cracking performance, and the effect of increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

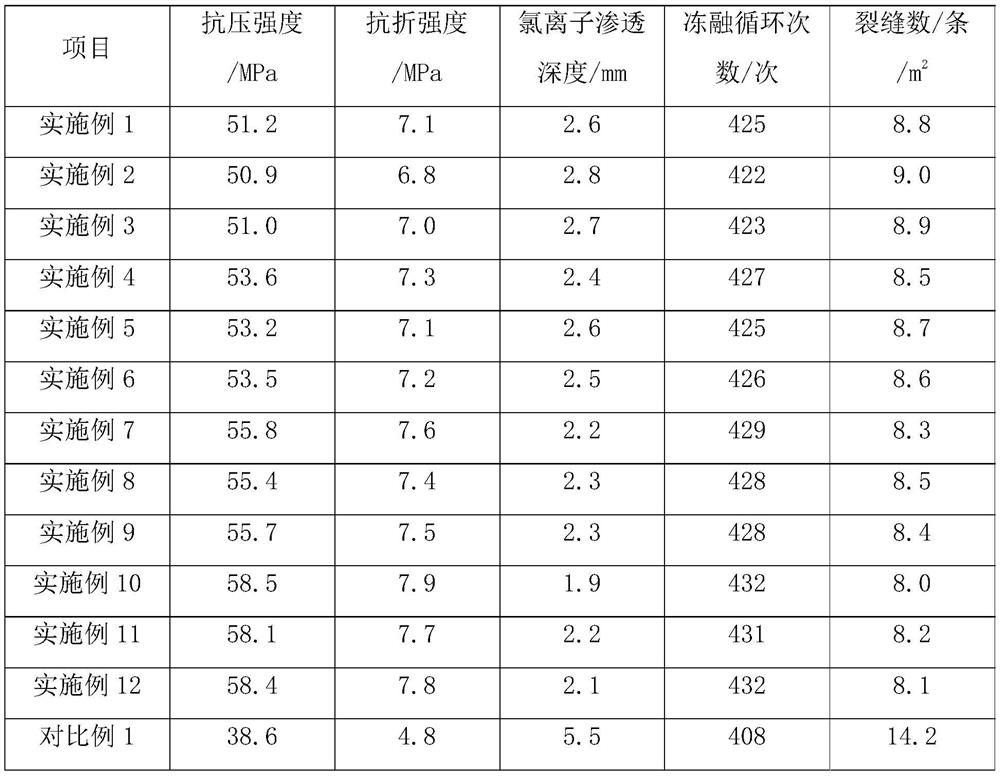

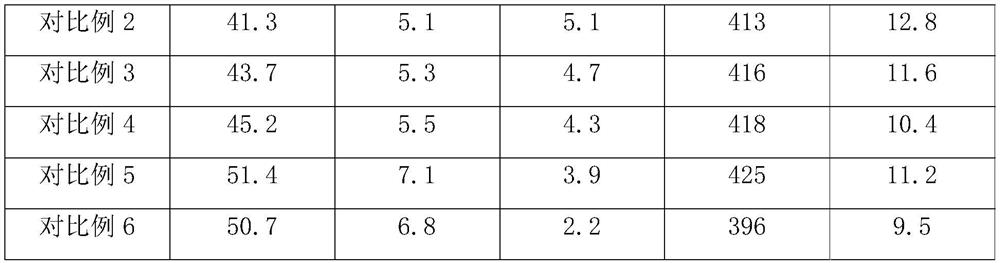

Examples

preparation example 1

[0038] Preparation example 1: Modified asbestos fiber is prepared by the following method:

[0039] ① Weigh 4.5kg of 2-hydroxyethyl acrylate and place it in 55kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0040] ② Weigh 45kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, press the cap with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 type electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 30min, and the modified asbestos fiber is obtained .

preparation example 2

[0041] Preparation example 2: Modified asbestos fiber is prepared by the following method:

[0042] ① Weigh 2kg of 2-hydroxyethyl acrylate and place it in 45kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0043] ②Weigh 35kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, cover with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 25min, and the modified asbestos fiber is obtained .

preparation example 3

[0044] Preparation example 3: Modified asbestos fiber is prepared by the following method:

[0045] ① Weigh 6kg of 2-hydroxyethyl acrylate and place it in 65kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0046] ② Weigh 55kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, cover with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 type electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 35min, and the modified asbestos fiber is obtained .

[0047] Preparation example of composite fiber

[0048] The polylactic acid fibers in the following raw materials were purchased from polylactic acid staple fibers produced by Shaoxing Xineng Textile Technology Co., Ltd., with a length of 6mm; polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com