Preparation method of porous scale inhibition ceramic and application thereof

A scale and ceramic technology, applied in the field of preparation of porous scale inhibitors, can solve the problems of slow-release phosphate scale inhibitor particle shape collapse, short service life, affecting scale life, etc., to achieve large water flux and resistance The effect of scale life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] This embodiment provides a method for preparing a scale-inhibiting porous ceramic membrane, including:

[0096] (1) According to the mass ratio of 20 parts of ammonium dihydrogen phosphate, 40 parts of diatomaceous earth, 10 parts of calcium oxide, 20 parts of kaolin, and 10 parts of CMC solution with a mass fraction of 5%, the above powder is placed in a mixer at 1000r / min speed stirring 20min granulation;

[0097] (2) Place the prepared ceramic pellets in a stainless steel mould, press under a dry press with a pressure of 2 t, and obtain a green body of a scale-inhibiting ceramic porous membrane after demoulding and dry it;

[0098] (3) Place the dried scale-inhibiting ceramic porous membrane green body in an industrial electric furnace for sintering. The sintering process is as follows: heating up to 200°C, heating rate 5°C / min, holding at 200°C for 1 hour, continuing to heat up to 600°C, and heating The rate is 5°C / min, the temperature is kept at 600°C for 1 hour,...

Embodiment 2

[0103] This embodiment provides a method for preparing a porous scale-inhibiting ceramic membrane, including:

[0104] A. Preparation of precursor powder:

[0105] (1) Mix the two powders according to the mass ratio of 10 parts of disodium hydrogen phosphate and 90 parts of diatomaceous earth, and place them in a mixer to stir at a rate of 1000r / min for 10 minutes. The powder is passed through a 300-mesh sieve to obtain a powder;

[0106] (2) The powder is packed in a sagger, and placed in an industrial electric furnace for heat treatment to obtain the scale-inhibiting porous ceramic precursor powder;

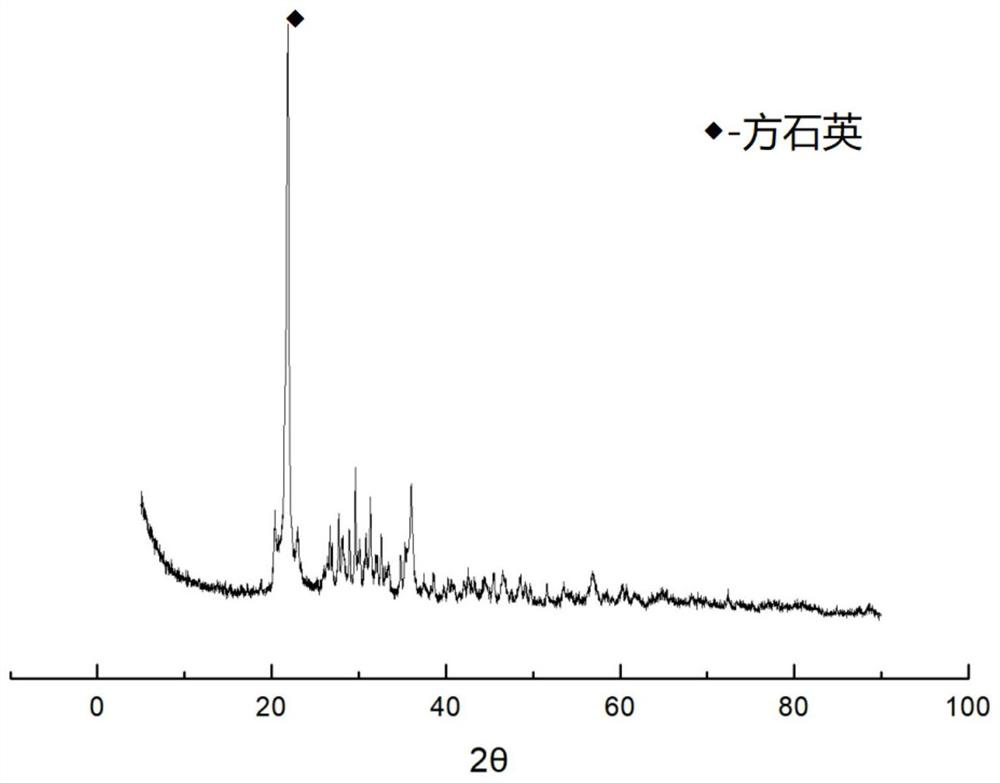

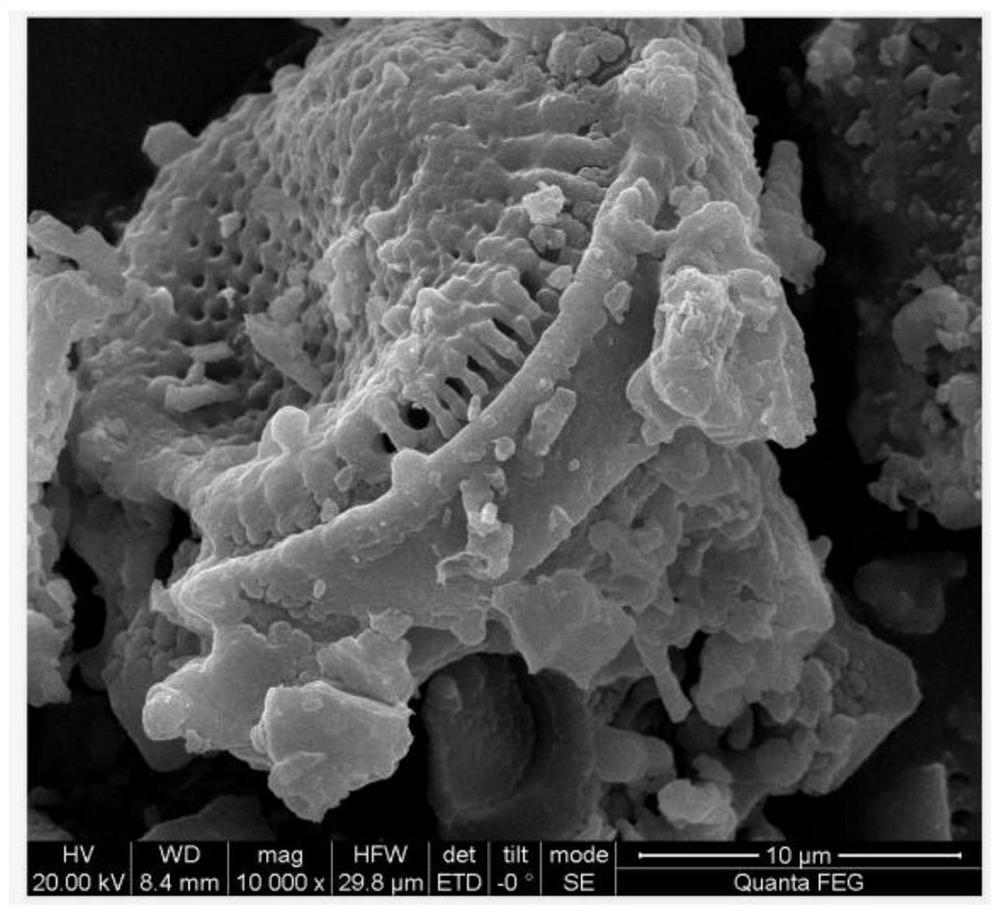

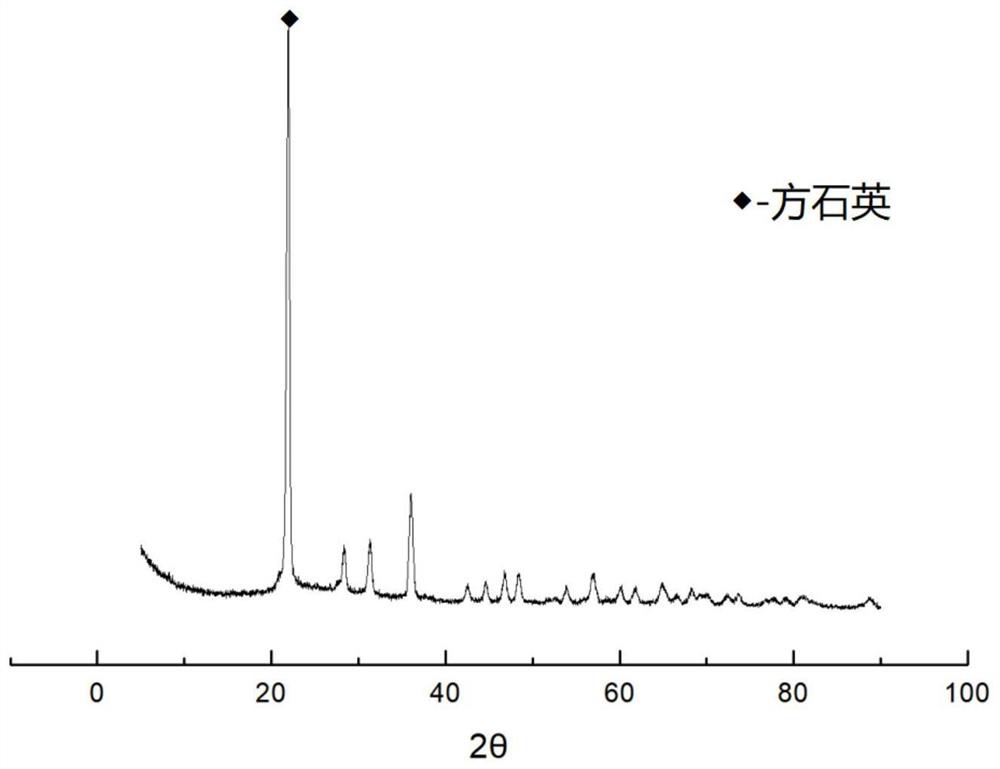

[0107] (3) The heat treatment method is: heating up to 200°C with a heating rate of 5°C / min, and holding at 200°C for 1 hour, then heating up to 800°C, with a heating rate of 5°C / min, and holding at 800°C for 2 hours to obtain the precursor powder , its XRD and SEM are detailed in image 3 and Figure 4 .

[0108] B. Preparation of scale-inhibiting porous ceramic membrane:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com