Anti-corrosion and anti-scaling combined agent and preparation method

A technology of combining chemicals, corrosion and scale inhibition, applied in chemical instruments and methods, descaling and water softening, natural water treatment, etc. The effect of time limit, low operating cost and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a kind of preparation method of above-mentioned polyether ester compound, comprises as follows:

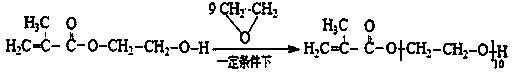

[0039] 1) Hydroxyethyl methacrylate is used as a raw material, and reacts with ethylene oxide under low-temperature acidic conditions until the infrared spectrum reaches 910cm -1 The peak of the epoxy group disappears, and the first reaction intermediate is obtained.

[0040]

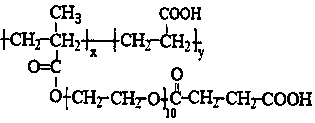

[0041] 2) Add succinic anhydride to the first reaction intermediate obtained in step 1), and react for a certain period of time under medium temperature conditions to obtain polyether ester monomers. In the infrared spectrum, 1200cm -1 The ether group peak appears.

[0042]

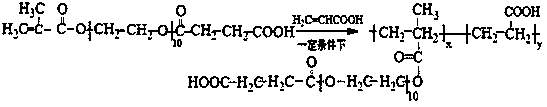

[0043] 3) The polyether ester monomer obtained in step 2) is thermally initiated to polymerize with acrylic acid, and the reaction is certain

[0044] The polyether ester compound containing carboxyl and hydrophilic groups with a molecular weight of 20,000-30,000 was obtained.

[0045] ...

specific Embodiment approach

[0065] Sewage zero-discharge corrosion and scale inhibitor composition, its composition is: 15%-20% of the compound of the present invention, 10%-15% of chelating agent, 5%-10% of scale and dispersant, 2%-5% % flocculants, surfactants, etc.

[0066] The compound of the present invention is a polyether ester compound;

[0067] The chelating agent is two or more of ethylenediaminetetraacetic acid, diethylenetriaminepentamethylenephosphonic acid, diethyltriaminepentaacetic acid or ethylenediaminetetramethylenephosphonic acid;

[0068] The scale inhibitor dispersant is one or both of polyaspartic acid, sodium polyacrylate, and hydrolyzed polymaleic anhydride;

[0069] The flocculant is one or both of chitosan or tannin;

[0070] The surfactant is one or both of fatty alcohol polyoxyethylene ether or sorbitan ester.

Embodiment 1

[0072] The pharmaceutical sewage of a chemical factory in Shandong is reused as circulating cooling water. The corrosion and scale inhibitor composition of the present invention is added to the system and mixed according to the following ratio: 20% polyether ester compound, diethylenetriaminepentamethylenephosphonic acid 10%, diethyltriaminepentaacetic acid 5%, polyaspartic acid 7.5%, chitosan 3%, fatty alcohol polyoxyethylene ether 0.5%, water balance.

[0073] In the sewage of this unit, the chlorine ion is 249.9 mg / L, the alkalinity is 2.0 mmol / L, the hardness is 3.0 mmol / L, the calcium ion is 40.08 mg / L, the magnesium ion is 12.25 mg / L, the total iron is 2.66 mg / L, and the total phosphorus is 26.3 mg / L. L, sulfate radical 979.53 mg / L, COD4802 mg / L, NH 3 -N 127.8 mg / L, the water quality is particularly poor, and the cost of wastewater treatment is also high. After entering the zero-sewage system, the equipment was corroded and fouled seriously, and the high-pressure water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com