Supercritical micro-foaming polyurethane material

A polyurethane material, supercritical technology, applied in the field of polyurethane foam materials, can solve the problems of poor flame retardancy, poor mechanical properties of polyurethane, easy to cause fire, etc., to improve mechanical properties and flame retardancy, solve cracking, and improve mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

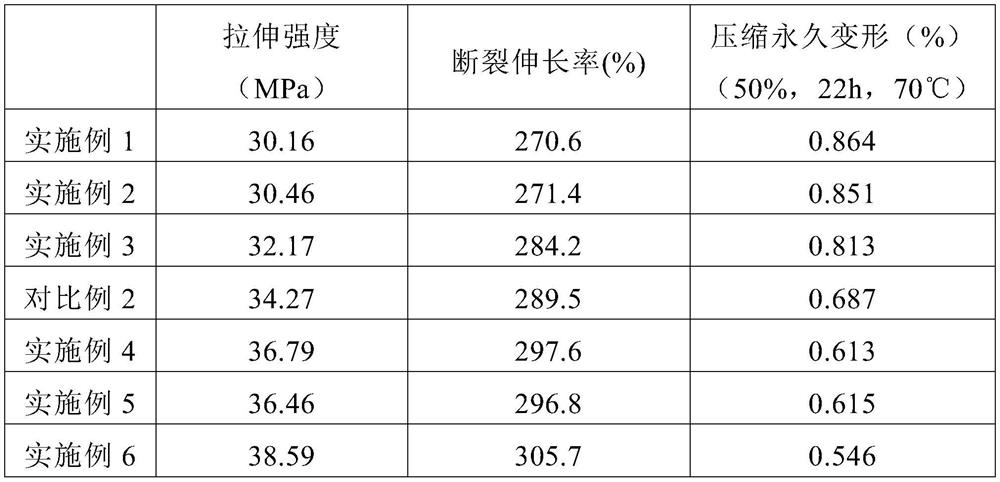

Examples

Embodiment 1

[0045] The supercritical micro-foamed polyurethane material includes the following raw materials in parts by weight: 30 parts of polycaprolactone diol, 36 parts of dodecylbenzene-2,4-diisocyanate, 6 parts of ricinoleyl alcohol, 1 part of dibutyltin dilaurate 0.5 parts of vinyltriethoxysilane, 2 parts of cyclopentane, 1.5 parts of surfactant, and 1.5 parts of nucleating agent.

[0046] Described tensio-active agent is epoxidized soybean oil;

[0047] The nucleating agent is rectorite.

[0048] The preparation method of described supercritical micro-foaming polyurethane material, comprises the following steps:

[0049] S1. Weigh respectively by weight: polycaprolactone diol, dodecylbenzene-2,4-diisocyanate, ricinoleyl alcohol, dibutyltin dilaurate, vinyltriethoxysilane, cyclopentyl alkanes, surfactants, nucleating agents;

[0050] S2, polycaprolactone diol, dodecylbenzene-2,4-diisocyanate, dibutyltin dilaurate, vinyltriethoxysilane, nucleating agent are mixed, in N 2 Heating...

Embodiment 2

[0054] The supercritical micro-foamed polyurethane material includes the following raw materials in parts by weight: 30 parts of polycaprolactone diol, 36 parts of dodecylbenzene-2,4-diisocyanate, 6 parts of ricinoleyl alcohol, 1 part of dibutyltin dilaurate 0.5 parts of vinyltriethoxysilane, 2 parts of cyclopentane, 1.5 parts of surfactant, and 1.5 parts of nucleating agent.

[0055] Described tensio-active agent is epoxidized soybean oil;

[0056] The nucleating agent is modified rectorite;

[0057] The preparation method of the modified rectorite: (1) Mix 5 parts by weight of phosphoric acid and 10 parts by weight of urea, raise the temperature to 120°C, stir at 1200rpm for 40min, lower the temperature to 80°C, add 4 parts by weight of Stirstone, 15 parts by weight of deionized water, and 1 part by weight of a modifying agent were stirred at 80° C. for 6 hours at 500 rpm. After the reaction, the product was put into an oven at 180° C. for curing for 3 hours to obtain modif...

Embodiment 3

[0064] The supercritical micro-foamed polyurethane material includes the following raw materials in parts by weight: 30 parts of polycaprolactone diol, 36 parts of dodecylbenzene-2,4-diisocyanate, 6 parts of ricinoleyl alcohol, 1 part of dibutyltin dilaurate 0.5 parts of vinyltriethoxysilane, 2 parts of cyclopentane, 1.5 parts of surfactant, and 1.5 parts of nucleating agent.

[0065] Described tensio-active agent is modified epoxy soybean oil;

[0066] The preparation method of the modified epoxy soybean oil: mix 25 parts by weight of epoxy soybean oil and 1 part by weight of 2mol / L potassium hydroxide solution, stir at 650rpm for 10min, add 10 parts by weight of chlorinated paraffin and heat to 60°C, Insulate for 40 minutes, add 1 part by weight of cetyltrimethylammonium bromide, stir at 700 rpm for 30 minutes, raise the temperature to 80° C. and continue stirring for 60 minutes, and naturally cool to room temperature to obtain modified epoxy soybean oil.

[0067] The nucle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com