Fluorine-free super-hydrophobic modified silicon dioxide composite resin coating and preparation method thereof

A hydrophobic silica and silica technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of harm to human health, low mechanical properties, high cost, and achieve a wide range of applications, good cost advantages, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

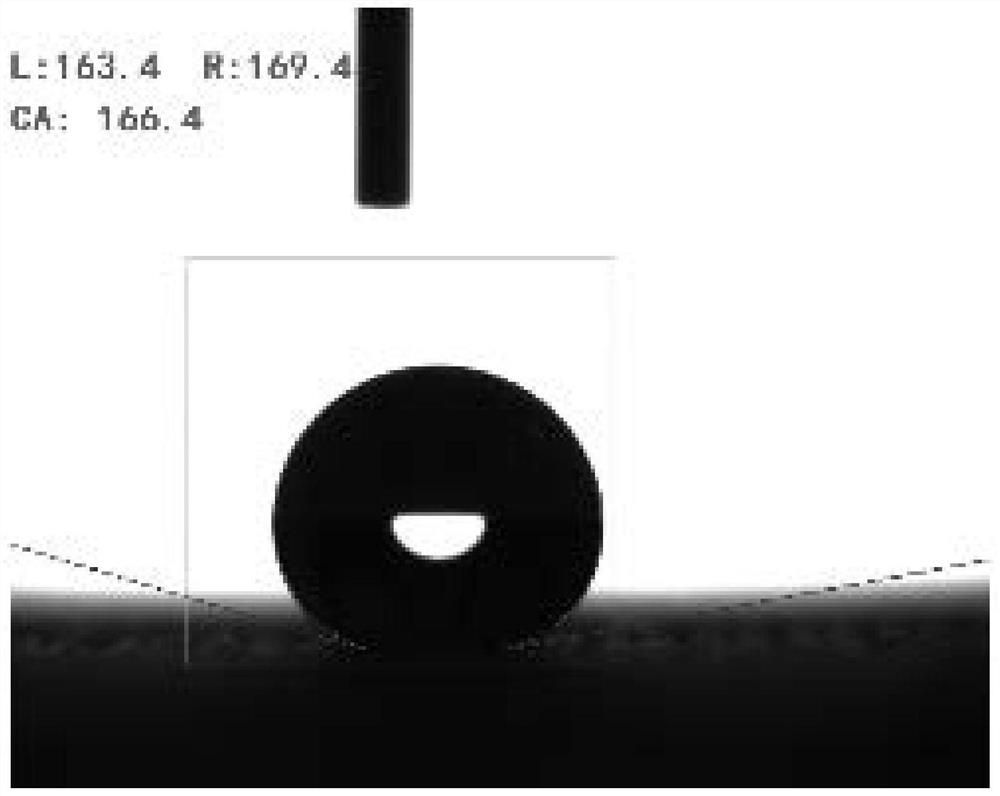

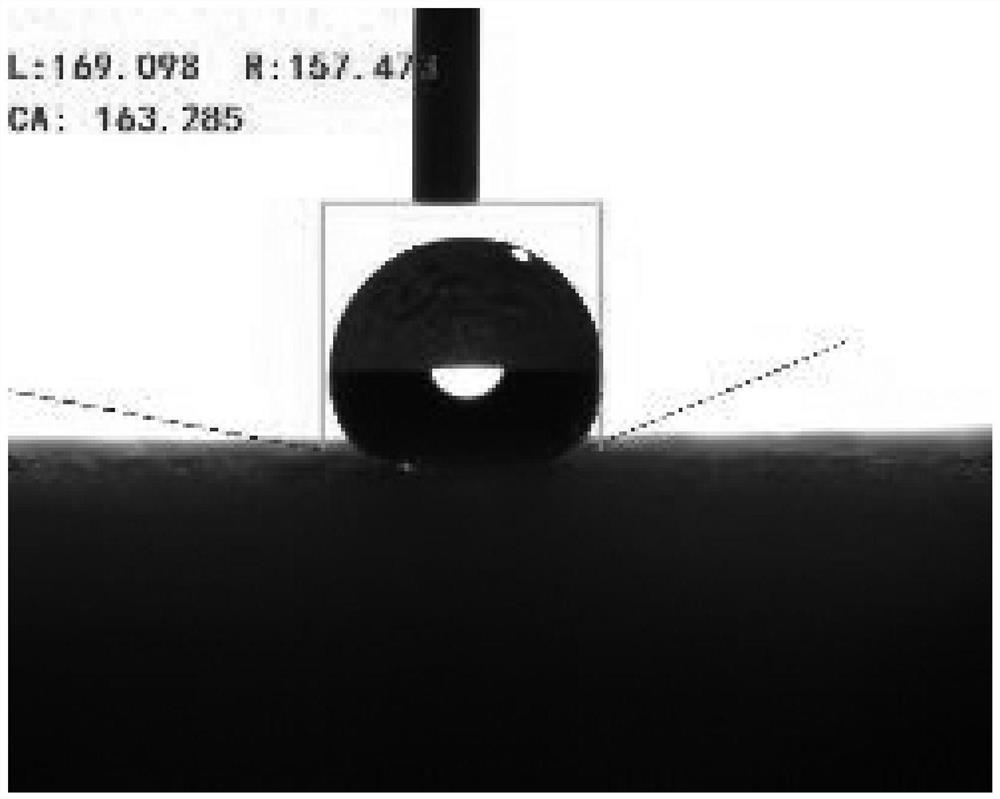

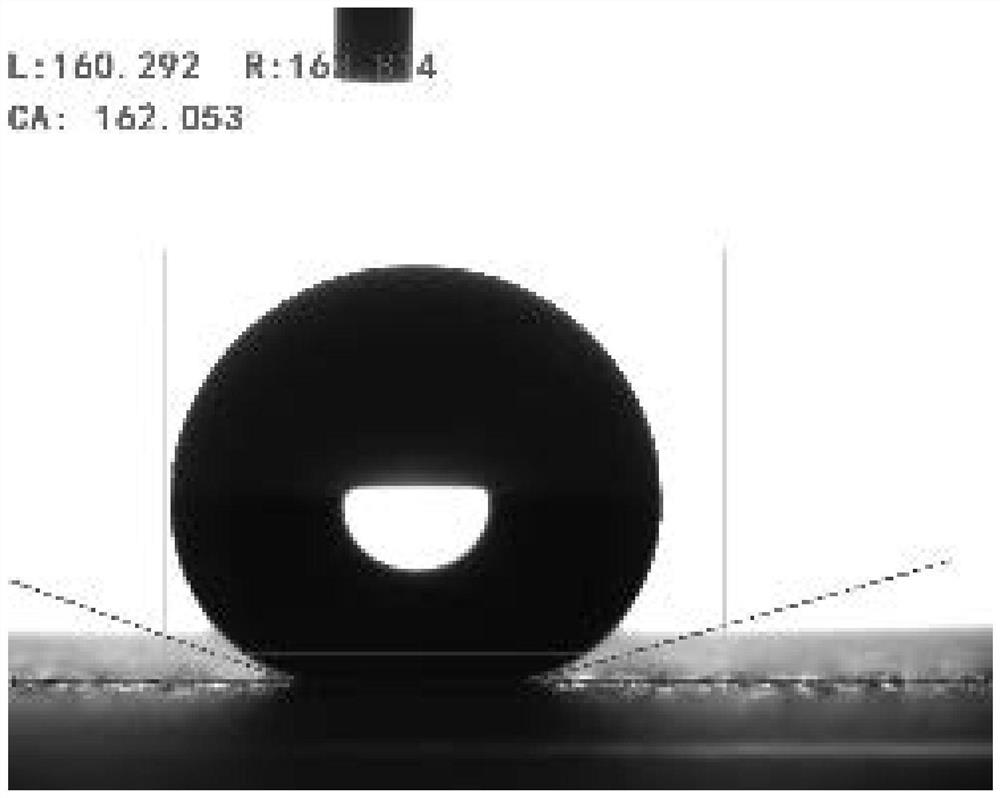

[0085] The preparation step of the modified superhydrophobic silicon dioxide coating has low requirements on process implementation conditions, is easy to operate, and has good cost advantages.

[0086] The modified silica sol with superhydrophobic properties has extremely low surface energy and is not easy to adhere to the surface of the substrate to be treated. As a bonding material, organosiloxane polymer has good film-forming properties and good compatibility with silica sol, and the main chain of silicon-oxygen bonds contained in it can prevent the mixture with modified silica sol from destroying the structure of each other. The composite resin coating has not only the superhydrophobicity of modified silica sol, but also the excellent film-forming performance and adhesion of organosiloxane polymer.

[0087] Too much modified hydrophobic silica sol in the coating and too little organosiloxane polymer will lead to insufficient adhesion between the coating and the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com