High-performance single-component organic silicon modified epoxy heat-conducting material and preparation method thereof

A heat-conducting material and organosilicon technology, which is applied in the field of high-performance single-component organosilicon-modified epoxy heat-conducting materials and its preparation, can solve the problems of unsatisfactory material adhesion, service stability, and reduced mechanical properties, and achieve good performance. Effect of heat dissipation, good bond strength and toughness, good thermal conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a high-performance single-component organosilicon-modified epoxy thermally conductive material, comprising the following steps;

[0048] (ⅰ) Drying of thermally conductive powder

[0049] Bake the conductive powder at 60°C for 60h-80h to remove moisture;

[0050] (ii) The particle size of the thermally conductive powder is extremely matched

[0051] The particle size of the heat-conducting powder is perfectly matched, and the heat-conducting powder of three particle sizes, large, medium and small, is pre-mixed according to the weight ratio of 8:6:1, so that the heat-conducting powder of three different particle sizes is initially mixed;

[0052] (Ⅲ) Thermally conductive powder coating

[0053] Surface treatment is performed on the powder obtained in step (ii) by a wet method to obtain a thermally conductive powder coated with a titanate coupling agent;

[0054] (ⅳ) mixed

[0055] First, fully mix the silicone-modified epoxy resin with the cros...

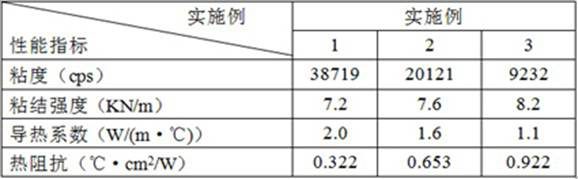

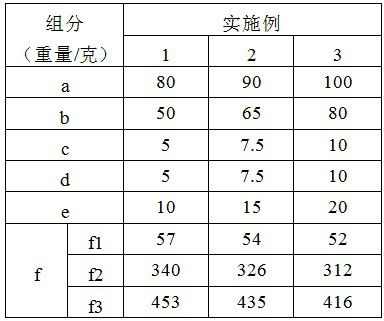

Embodiment 1~3

[0057] (1) Prepare raw materials

[0058] a. Silicone modified epoxy resin with a viscosity of about 90cps;

[0059] b. Methyl hexahydrophthalic anhydride;

[0060] c. Dicyandiamide accelerator;

[0061] d. Polypropylene glycol diglycidyl ether;

[0062] e. Titanate coupling agent KR-TTS;

[0063] f. Thermally conductive powder;

[0064] Among them: f1 zinc oxide powder (average particle size 0.6μm);

[0065] f2 alumina powder (average particle size 25μm);

[0066] f3 Aluminum powder (average particle size 60μm).

[0067] The above-mentioned heat-conducting powder f that has been dewatered is mixed according to the ratio shown in Table 1, and then the surface of the mixed powder is treated by wet method, so that the surface is coated with a layer of titanate coupling Agent e thermal conductive powder.

[0068] Put the above components a, b, c, d in proportion (see Table 1 for the specific components and their ratios) into a high-speed disperser for 10 to 20 minutes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com