Preparation method of acidic degreaser for PCB

A PCB circuit board, acid degreasing technology, applied in chemical instruments and methods, surface active detergent compositions, detergent compounding agents, etc., can solve problems that affect the production and processing of PCB circuit boards, affect work efficiency, and cannot remove oil and other problems to achieve the effect of speeding up air-drying time, improving work efficiency, and improving oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for an acid degreaser for PCB circuit boards, characterized in that, in terms of weight components, wherein the raw materials include the following components: 80-100 parts of deionized water, 22-34 parts of cycloalkane, 18-34 parts of ethanol 30 parts, organic amine ester 10-20 parts, emulsifier 5-10 parts, metal cleaning agent 10-20 parts and surfactant 4-8 parts.

[0025] The cycloalkane is isooctane.

[0026] Ethanol and water were mixed and stirred so that the concentration of the ethanol solution was 0.65 g / ml.

[0027] The emulsifier is ethylene oxide.

[0028] The surfactant is sodium dodecylbenzenesulfonate.

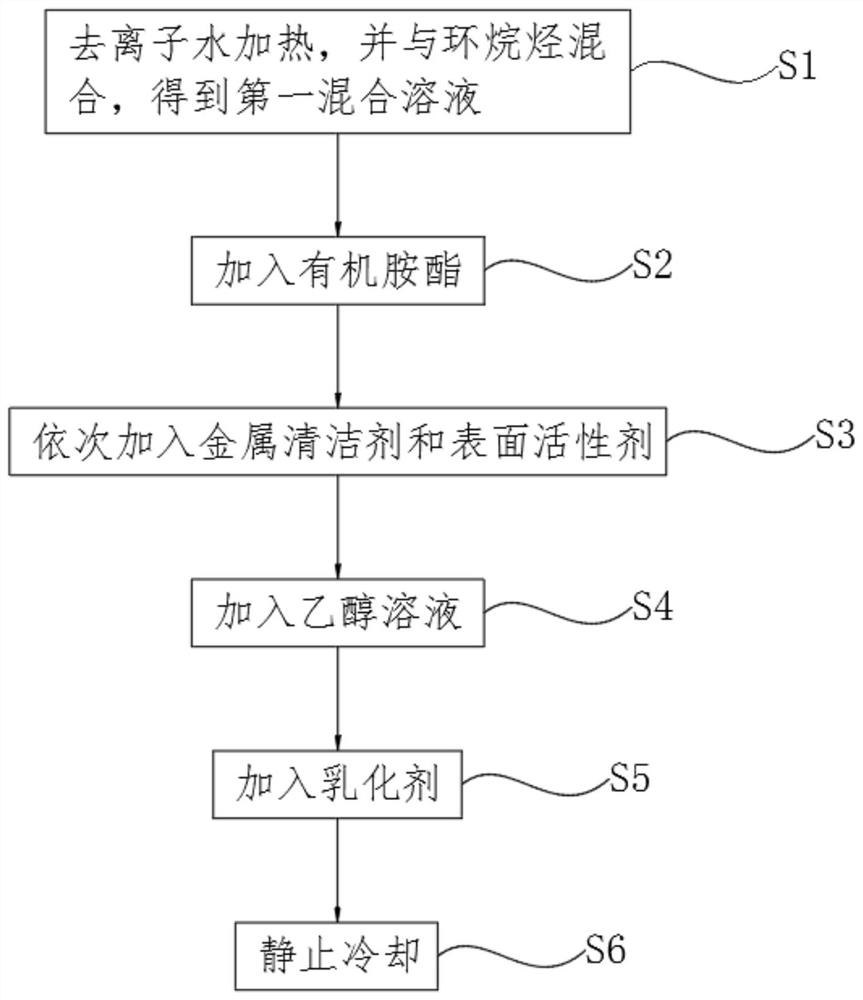

[0029] A kind of preparation method for the acid degreasing agent of PCB circuit board, it is characterized in that, it is characterized in that comprising the following steps:

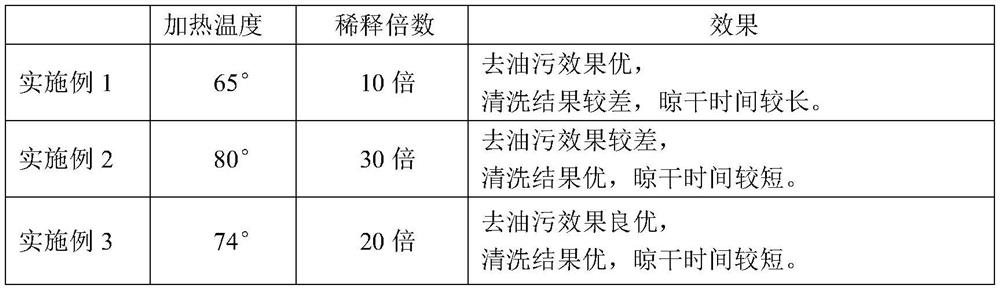

[0030] S1: Evenly heat 80 parts of deionized water to 65°, then add 22 parts of isooctane into the deionized water, and add it uniformly and slowly and st...

Embodiment 2

[0038] A preparation method for an acid degreaser for PCB circuit boards, characterized in that, in terms of weight components, wherein the raw materials include the following components: 80-100 parts of deionized water, 22-34 parts of cycloalkane, 18-34 parts of ethanol 30 parts, organic amine ester 10-20 parts, emulsifier 5-10 parts, metal cleaning agent 10-20 parts and surfactant 4-8 parts.

[0039] The cycloalkane is cyclopentane.

[0040] Ethanol and water were mixed and stirred so that the concentration of the ethanol solution was 0.8 g / ml.

[0041] The emulsifier is fatty acid ester.

[0042] The surfactant is triethanolamine soap.

[0043] A kind of preparation method for the acid degreasing agent of PCB circuit board, it is characterized in that, it is characterized in that comprising the following steps:

[0044] S1: uniformly heat 100 parts of deionized water to 80°, then add 30 parts of cyclopentane into the deionized water, and add it evenly and slowly and stir...

Embodiment 3

[0052] A preparation method for an acid degreaser for PCB circuit boards, characterized in that, in terms of weight components, wherein the raw materials include the following components: 80-100 parts of deionized water, 22-34 parts of cycloalkane, 18-34 parts of ethanol 30 parts, organic amine ester 10-20 parts, emulsifier 5-10 parts, metal cleaning agent 10-20 parts and surfactant 4-8 parts.

[0053] The cycloalkane is cyclohexane.

[0054] Ethanol and water were mixed and stirred so that the concentration of the ethanol solution was 0.75 g / ml.

[0055] The emulsifier is polyoxypropylene ether.

[0056] The surfactant is an alkyl sulfate.

[0057] A kind of preparation method for the acid degreasing agent of PCB circuit board, it is characterized in that, it is characterized in that comprising the following steps:

[0058] S1: Evenly heat 90 parts of deionized water to 74°, then add 25 parts of cyclohexane into the deionized water, and add it evenly and slowly and stir it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com