Drainage pavement structure

A technology of pavement structure and drainage asphalt, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of inability to achieve anti-cracking effect, can not be used for drainage and noise reduction pavement, stress concentration, etc., to overcome poor shear resistance, Improved durability and excellent fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Further, the present invention also provides a method for preparing the drainage asphalt mixture in the drainage pavement structure, which includes the step of mixing the components of the drainage asphalt mixture.

[0083] Specifically, the preparation method of the drainage asphalt mixture of the present invention includes the following steps: first mix the composite fiber, then dry mix with the coarse aggregate and fine aggregate in the graded aggregate, and then add SBS modified asphalt and mix After continuing to add ore powder and stir, the drainage asphalt mixture is obtained.

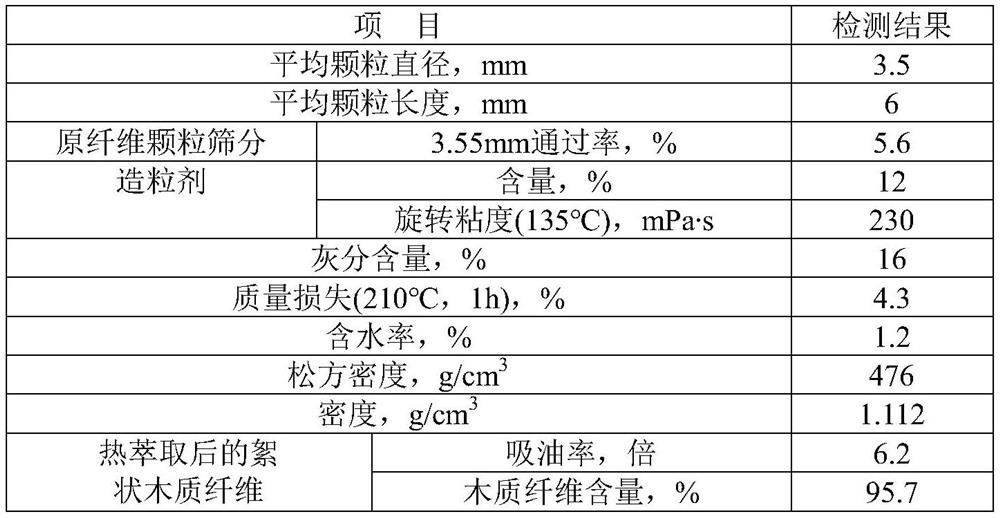

[0084] Further, weigh granular lignin fiber and glass fiber respectively, stir the two fibers evenly at room temperature, dry mix with coarse aggregate and fine aggregate for 50-150s, and finally add SBS at a temperature of 150-200°C Stir the modified asphalt for 80-160s, and finally add mineral powder and stir quickly. During the mixing process, try to make the composite fiber evenly di...

Embodiment 1

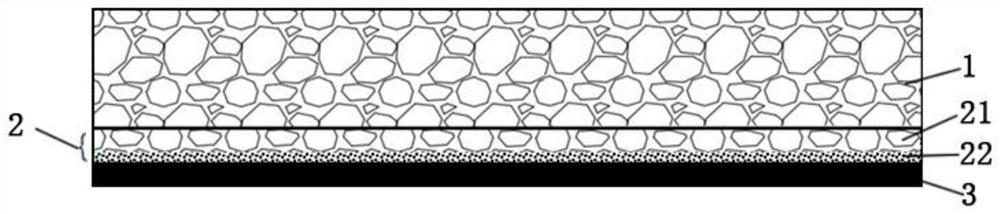

[0110] According to the designed gradation, the drainage asphalt mixture was prepared under the condition of 7% asphalt dosage of the total mass of the graded aggregate, in which the total mass of the graded aggregate was about 1121.5g: the first asphalt layer 1 was the drainage asphalt layer, and the Drainage asphalt mixture, the porosity of the first asphalt layer 1 is 11%; the construction thickness is 4cm. The specific preparation method is as follows:

[0111] Dry the coarse aggregate and fine aggregate at a temperature of 105° C., weigh 1.8 g of granular lignin fiber and 1.8 g of glass fiber (that is, the mass ratio of granular lignin fiber to glass fiber is 1:1), mix the two kinds of fibers evenly at room temperature, then dry mix them with the washed and dried coarse aggregate and fine aggregate for 90s, then add 78.5g of SBS modified asphalt at a temperature of 180°C and stir 120s, and finally add mineral powder and stir quickly. During the mixing process, try to ma...

Embodiment 2

[0116] According to the designed gradation, the drainage asphalt mixture was prepared under the condition of 7% bitumen content of the total mass of the graded aggregate, and the total mass of the graded aggregate was about 1121.5g. The first asphalt layer 1 is a drainage asphalt layer, and the drainage asphalt mixture is used. The porosity of the first asphalt layer 1 is 11%; the construction thickness is 4cm.

[0117] Dry the coarse aggregate and fine aggregate at a temperature of 105° C., weigh 2.4 g of granular lignin fiber and 1.2 g of glass fiber (that is, the mass ratio of granular lignin fiber to glass fiber is 2:1, after mixing the two fibers evenly at room temperature, dry mix them with the washed and dried coarse aggregate and fine aggregate for 90s, then add 78.5g of SBS modified asphalt at a temperature of 180°C and stir for 120s , and stir rapidly after adding the mineral powder at last. During the stirring process, the composite fiber is evenly distributed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com