Full-prefabricated assembled structure bridge suitable for grassland wetlands and construction method thereof

A technology of prefabricated assembly and construction methods, which is applied in the direction of foundation structure engineering, erection/assembly of bridges, bridges, etc., can solve the problems of small diameter range of pile foundation, weak horizontal shear bearing capacity of pile foundation, and few applications, so as to achieve construction Small safety risk, short construction time, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

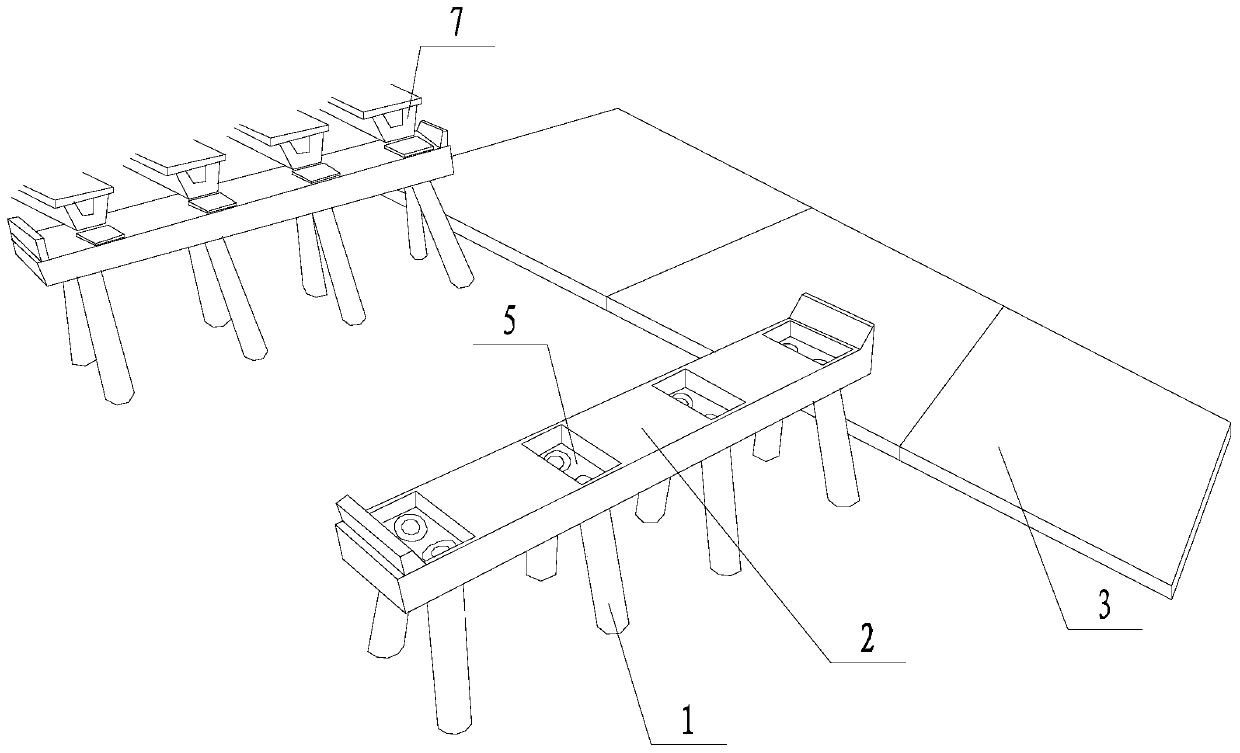

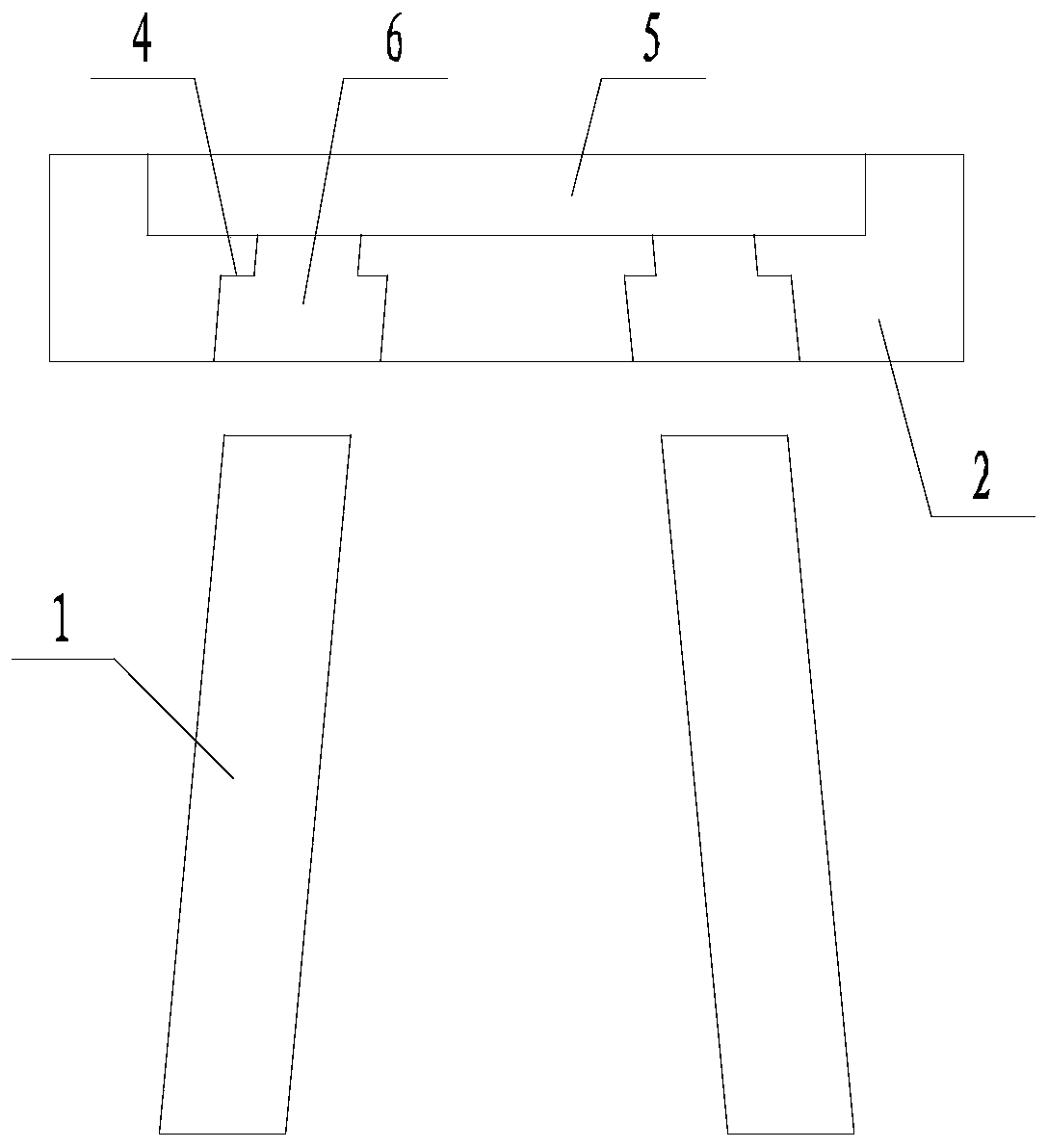

[0037] Such as figure 1 versus figure 2 A fully prefabricated assembled structure bridge suitable for prairie wetlands is shown, including a plurality of prefabricated cap beams (2), and a plurality of linearly distributed notches (5) are provided on the prefabricated cap beams (2), and each notch (5) are provided with two jacks (6), the axes of the two jacks (6) are inclined from top to bottom to the opposite outer sides of the prefabricated cover beam (2), and each jack (6) is Insert a matching prefabricated pipe pile (1), the top of the prefabricated pipe pile (1) and the corresponding socket (6) are fixed by cast-in-place concrete; the upper part is laid on two adjacent prefabricated cap beams (2) The structure (7), the upper structure (7) is a prefabricated small box beam or a prefabricated composite beam.

[0038] In this embodiment, according to the topography and landform conditions, combined with the route requirements, the wiring location layout plan is determined. Co...

Embodiment 2

[0040] Such as figure 1 versus figure 2 A fully prefabricated assembly structure bridge suitable for prairie wetlands is shown. On the basis of Example 1, the top surface of the prefabricated cap beam 2 is rectangular, and a number of slots 5 on the prefabricated cap beam 2 are along the length of the rectangle. The axis is distributed, and the two insertion holes 6 in each notch 5 are inclined toward the two sides of the long axis of the rectangle. A step 4 is provided in the jack 6, and the prefabricated pipe pile 1 cannot pass through the step 4 from bottom to top. The angle between the axis of the prefabricated pipe pile 1 and the vertical line is 8°. The prefabricated cover beam 2 is integrally prefabricated or split prefabricated; when the prefabricated cover beam 2 is prefabricated separately, two adjacent parts are connected by a wet joint. The prefabricated pipe pile 1 is a mixed-reinforced prefabricated prestressed pipe pile, the prefabricated small box beam is a p...

Embodiment 3

[0052] Prefabricated components such as prestressed pile foundations, prefabricated cover beams, 25-meter small box beams, etc., are prepared by purchasing industrial products or establishing prefabricated yards. Use the repaired road as a transportation channel to transport the components to be assembled to the bridge location. Lay load-bearing boards on the ground to provide driving channels for pile drivers and cranes. The pile driver travels to the pile position and inserts the prefabricated pipe piles. After all the pile foundations of the first and second piers are driven, the crane is used to install the prefabricated cover beams and handle the joints. Cushion stone for cast-in-place bridge pier cap beam support. After the support cushion stone reaches the strength, install the support, use the bridge frame to set up a 25-meter small box girder, bind the beam body and the wet joint steel bar, and choose the machine to cast the wet joint of the beam body. While erecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com