Bamboo fiber crisp and preparation method thereof

A technology for flaky crisps and raw materials, applied in the field of bamboo flaky crisps and their preparation, can solve the problems of thick and rough taste, bamboo shoot crisps cannot take into account high fiber and low sugar, and high sugar content, and achieves improved appearance and taste, great advantages and competition. Strength, health effect improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

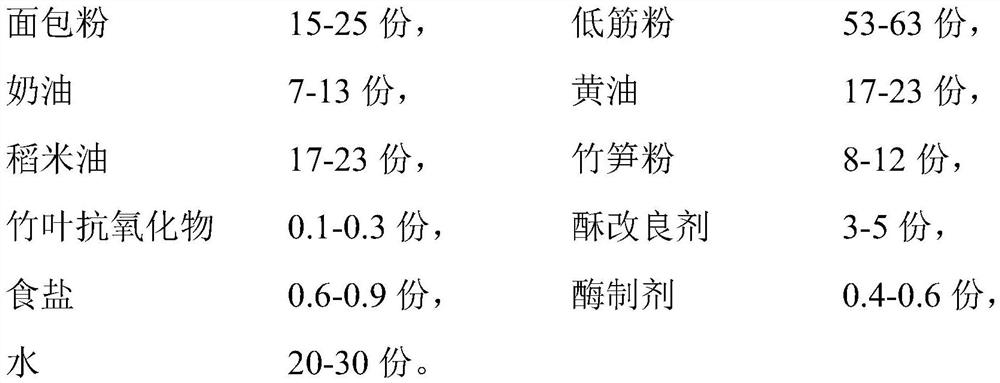

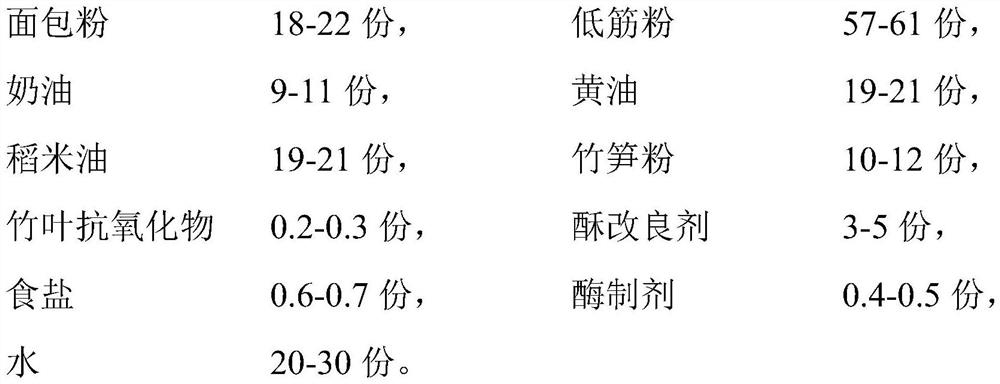

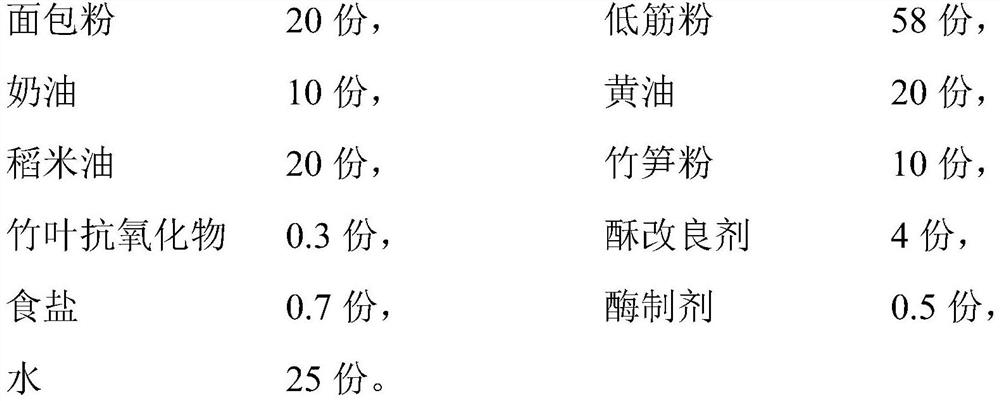

[0032] When the bamboo fiber crisp is prepared, the raw materials are taken in parts by weight: 10 parts of bamboo shoot powder, 0.3 part of bamboo leaf antioxidant, 20 parts of bread flour, 58 parts of low-gluten flour, 20 parts of butter, 10 parts of butter, 20 parts of rice oil, 3 parts of white sesame, 0.7 parts of salt, 4 parts of crisp improver, 0.5 parts of enzyme preparation, 25 parts of water.

[0033] The preparation process is as follows:

[0034] (1) Soften the butter, add rice oil, butter, bread flour, low-gluten flour, bamboo shoot powder, bamboo leaf antioxidant, crisp improver, salt, enzyme preparation, water and half of white sesame in turn, stir well and knead Knead the dough;

[0035] (2) Roll the dough into a crispy green body, and sprinkle the other half of the white sesame on the surface of the crispy green body, then put it in a rotary oven, and bake it at 180°C at 360° for 25-30min until the crispy golden yellow ;

[0036] (3) Take out the baked puff...

Embodiment 2

[0038] When the bamboo fiber crisp is prepared, the raw materials are taken in parts by weight: 10 parts of bamboo shoot powder, 0.3 part of bamboo leaf antioxidant, 20 parts of bread flour, 58 parts of low-gluten flour, 20 parts of butter, 10 parts of butter, 20 parts of rice oil, 12 parts of almond slices, 0.7 parts of salt, 4 parts of crisp improver, 0.5 parts of enzyme preparation, 25 parts of water.

[0039] The preparation process is as follows:

[0040] (1) Soften the butter, add rice oil, butter, bread flour, low-gluten flour, bamboo shoot powder, bamboo leaf antioxidant, crisp improver, salt, enzyme preparation, water and half of almond flakes in turn, stir well and knead Knead the dough;

[0041] (2) Roll the dough into a crispy green body, and sprinkle the other half of the almond slices on the surface of the crispy green body, then put it in a rotary oven, and bake it at 180°C at 360° for 25-30min until the crispy golden brown ;

[0042] (3) Take out the baked p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com