A kind of soil tangerine peel and preparation method thereof

A technology of tangerine peel and frying auxiliary materials, which is applied in the direction of medical formula, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of reducing the content of volatile oil active ingredients in tangerine peel, failing to fully exert the effect of tangerine peel, Product quality is difficult to control and other problems, to achieve the effect of reducing drug dryness, enhancing Qi and spleen, and reducing drug dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

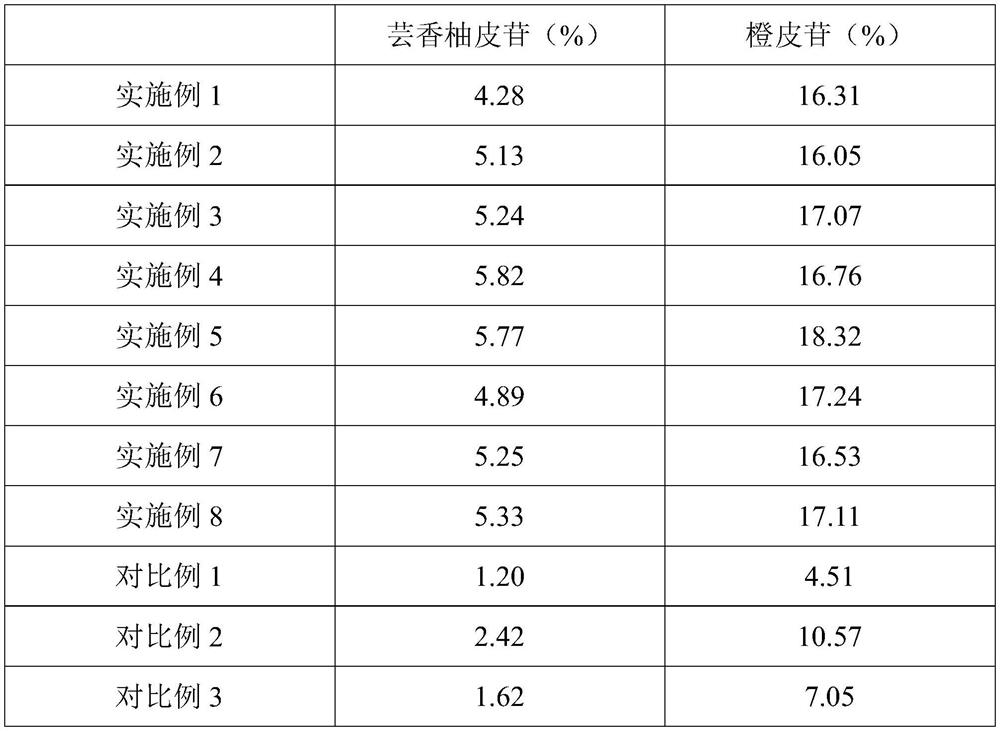

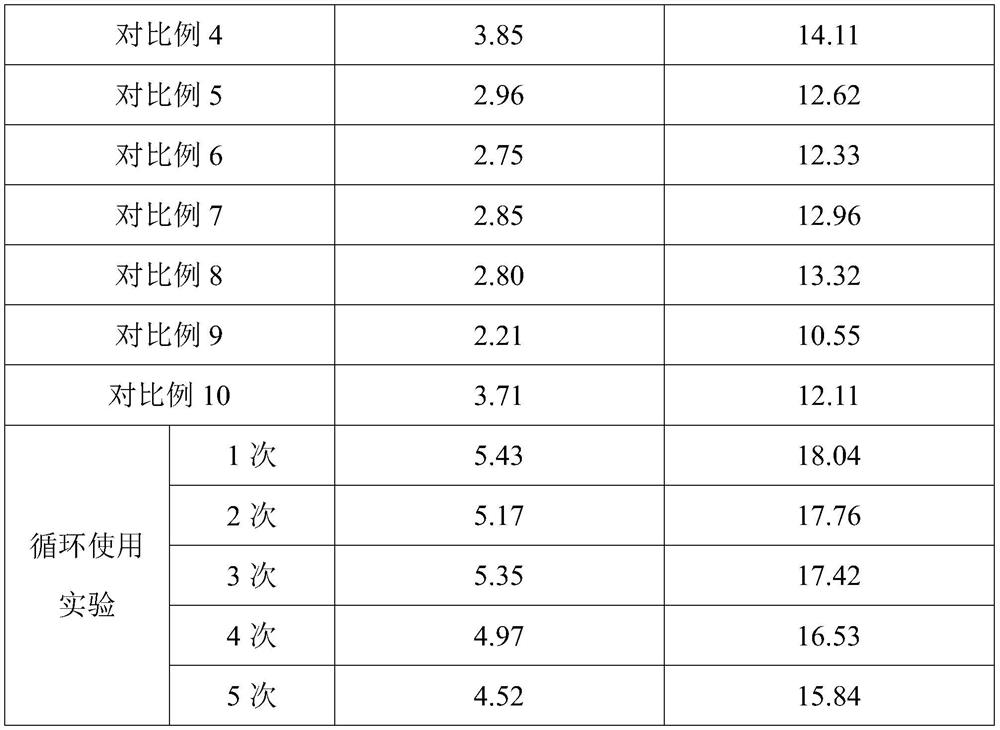

Examples

Embodiment 1

[0033] A preparation method of soil tangerine peel, comprising the following steps:

[0034] S1. Pretreatment: use an atomizing distributor to spray a pretreatment solution with 15% of the dried tangerine peel mass on the dried tangerine peel raw material, and moisten the dried tangerine peel for a certain period of time to make the dried tangerine peel moist; wherein, the pretreatment solution includes: 10 parts of vinegar, 50 parts of yellow rice wine , 2 parts of L-glycine; the moistening temperature is 25°C, and the time is 8min.

[0035] S2, shredded tangerine peel: cut the pretreated tangerine peel into shredded tangerine peel with a width of 2-3mm, and dry in the shade until the water content is 11-13%;

[0036] S3. Soil system of tangerine peel: Pass the soil fried auxiliary materials through a 60-mesh sieve. When the temperature in the pot reaches 80°C, put the soil fried auxiliary materials in the pot and stir-fry until smooth, pour in shredded orange peel, and stir-...

Embodiment 2

[0039] A preparation method of soil tangerine peel, comprising the following steps:

[0040] S1. Pretreatment: use an atomizing distributor to spray a pretreatment solution with 80% of the dried tangerine peel quality on the dried tangerine peel raw material, and moisten the dried tangerine peel for a certain period of time to make the dried tangerine peel moist; wherein, the pretreatment solution includes: 50 parts of vinegar, 50 parts of yellow rice wine , 10 parts of L-alanine, 5 parts of L-glutamic acid; the moistening temperature is 25°C, and the time is 30 minutes.

[0041] S2, shredded tangerine peel: cut the pretreated tangerine peel into shredded tangerine peel with a width of 5-6mm, and dry in the shade until the water content is 17-18%;

[0042] S3. Soil system of tangerine peel: Pass the soil fried auxiliary material through a 60-mesh sieve. When the temperature in the pot reaches 120°C, put the soil fried auxiliary material in the pot and fry until it becomes smoo...

Embodiment 3

[0045] A preparation method of soil tangerine peel, comprising the following steps:

[0046] S1. Pretreatment: use an atomizing distributor to spray a pretreatment solution with 30% of the dried tangerine peel mass on the dried tangerine peel raw material, and moisten the dried tangerine peel for a certain period of time to make the dried tangerine peel moist; wherein, the pretreatment solution includes: 20 parts of vinegar, 20 parts of yellow rice wine , 1 part of L-phenylalanine; the moistening temperature is 30°C, and the time is 25min.

[0047] S2, shredded tangerine peel: cut the pretreated tangerine peel into shredded tangerine peel with a width of 3-5mm, and dry in the shade until the water content is 13-16%;

[0048] S3. Soil system of tangerine peel: Pass the soil fried auxiliary material through a 60-mesh sieve. When the temperature in the pot reaches 140°C, put the soil fried auxiliary material in the pot and fry until it becomes smooth. It is burnt yellow and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com