A kind of imitation leaf porous film composite ppy/pva sponge and its preparation method and application

A porous membrane and sponge technology, applied in the field of imitation leaf porous membrane composite PPy/PVA sponge and its preparation, can solve the problems of low conversion efficiency of light, heat and steam, alleviate the global energy and fresh water shortage crisis, and have good desalination and purification capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

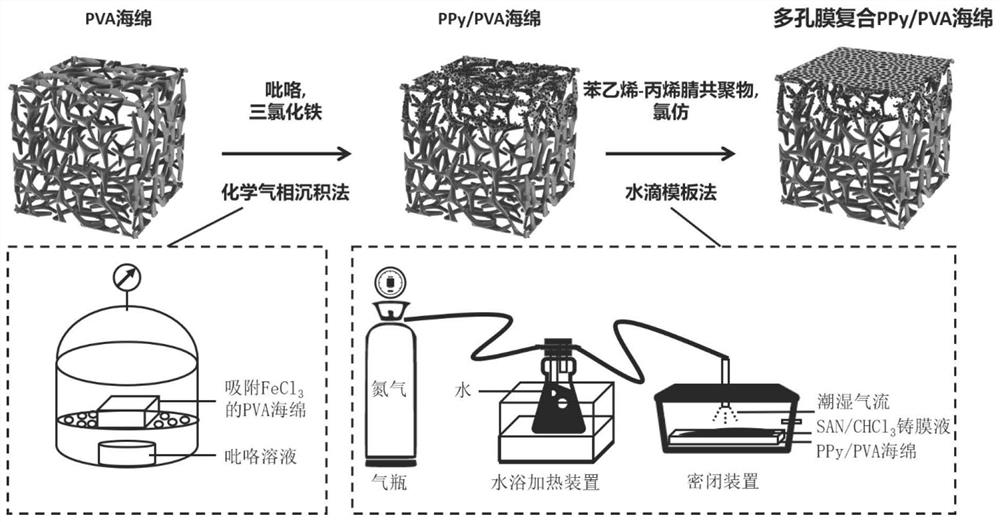

[0041] The invention provides a method for preparing a leaf-like porous film composite PPy / PVA sponge, comprising the following steps:

[0042] Soak the polyvinyl alcohol sponge in FeCl 3 In the solution, obtain the pretreatment polyvinyl alcohol sponge;

[0043] Contacting the pretreated polyvinyl alcohol sponge with pyrrole, and in-situ chemical vapor deposition of polypyrrole on the pretreated polyvinyl alcohol sponge to obtain a PPy / PVA sponge;

[0044] The PPy / PVA sponge is dipped in a styrene-acrylonitrile copolymer solution, and the water drop template method is used to form a film, so as to obtain the composite PPy / PVA sponge with imitation leaf porous membrane.

[0045] In the present invention, unless otherwise specified, the raw materials used are commercially available products in the art.

[0046] The present invention soaks polyvinyl alcohol (PVA) sponge in FeCl 3 After being removed from the solution, a pretreated polyvinyl alcohol sponge was obtained.

[00...

Embodiment 1

[0073] PPy / PVA sponges were prepared in a vacuum oven. Put ferric chloride and ethanol into an Erlenmeyer flask, stir at 25°C for 1 hour, and prepare FeCl with a FeCl concentration of 1mol / L 3 solution. PVA sponge (1cm3 ) into FeCl 3 Soak in the solution (1 mL), then take it out and place it in a vacuum drying oven with 2 mL of pyrrole, keep the vacuum degree of the vacuum drying oven at 0.6, the temperature at 25 ° C, and react for 4 hours. After the reaction, the sample was taken out and washed 3 times with absolute ethanol, and dried in a blast drying oven. The sponge appeared black, indicating that PPy had been successfully loaded on the PVA sponge to obtain a PPy / PVA sponge.

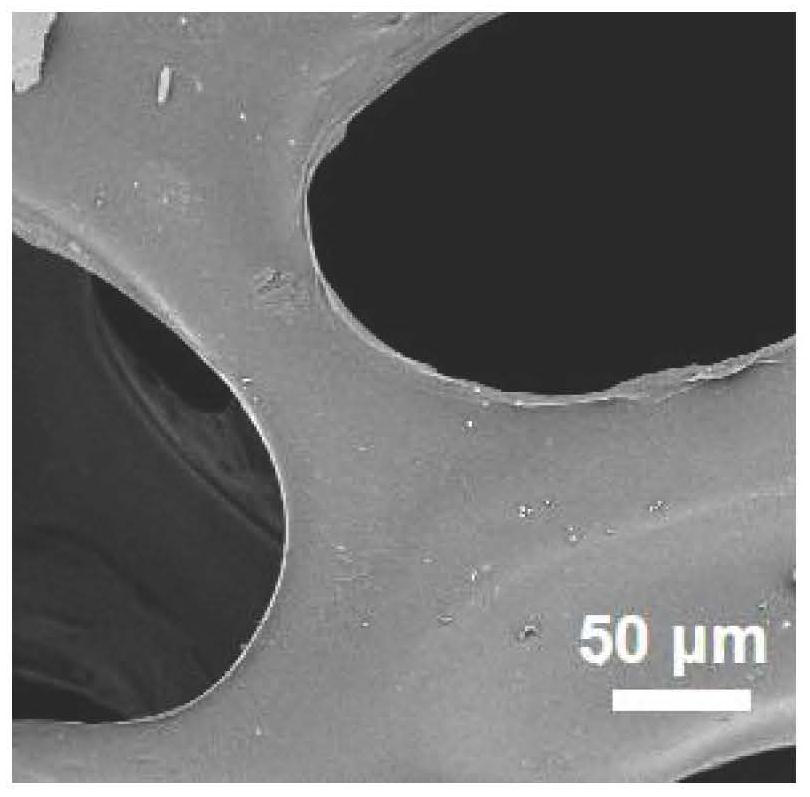

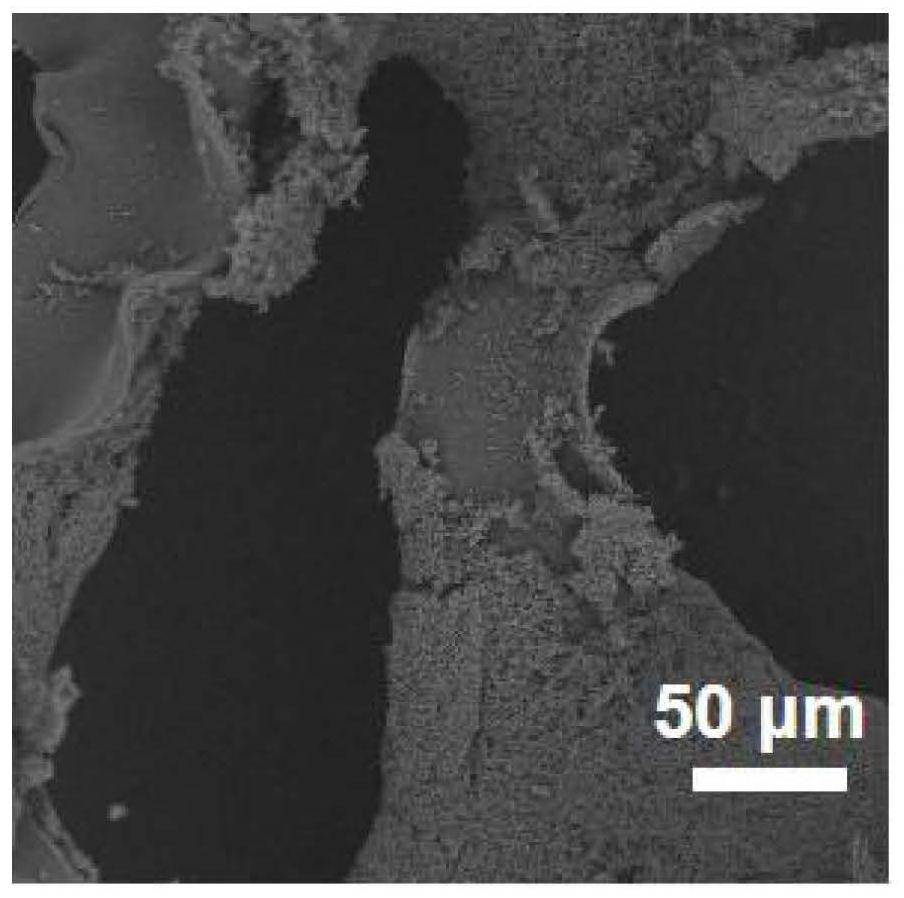

[0074] The SEM of the uncoated PPy PVA sponge and the prepared PPy / PVA sponge are as follows: figure 2 and image 3 shown. Depend on Figure 2~3 It can be seen that polypyrrole (PPy) has been successfully attached to the PVA sponge skeleton.

[0075] Put styrene-acrylonitrile copolymer and c...

Embodiment 2~5

[0082] Same as Example 1, the only difference is that the concentration of SAN in the SAN solution is adjusted to 0.018, 0.020, 0.022 and 0.024g / mL respectively, and the obtained imitation leaf porous membrane composite PPy / PVA sponge is respectively recorded as HPF-2 and HPF-3 , HPF-4 and HPF-5.

[0083] Figure 9 It is the electron micrograph of the imitation leaf porous membrane composite PPy / PVA sponge that embodiment 1~5 makes, wherein a is HPF-1, b is HPF-2, c is HPF-3, d is HPF-4, e is HPF -5. Figure 10 It is a comparison chart of the most probable pore diameter and the equivalent perimeter per unit area of the leaf-like porous membrane composite PPy / PVA sponge prepared in Examples 1-5. Depend on Figure 10 It can be seen that with the increase of the concentration of SAN solution, the pore size of the porous membrane layer of the leaf-like porous membrane composite PPy / PVA sponge (HPF) decreases, and the equivalent perimeter per unit area increases, HPF-1, HPF-2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com