High-entropy oxide film and preparation method and application thereof

An oxide thin film, high-entropy technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as limiting the application range of electronic devices, and achieve low cost , film performance is stable, and the operation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

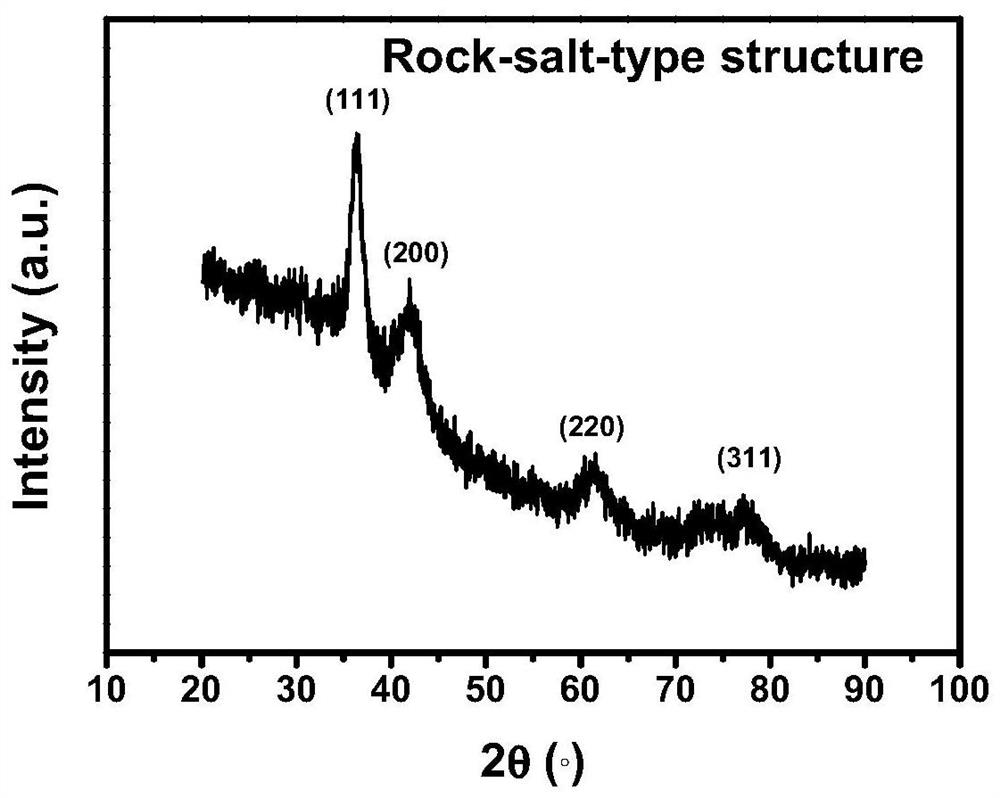

[0033] The present invention provides a kind of preparation method of high entropy oxide thin film, it is characterized in that, comprises the following steps:

[0034] Cutting the Co metal sheet, the Ni metal sheet, the Cu metal sheet and the Zn metal sheet respectively to obtain a Co fan-shaped metal sheet, a Ni fan-shaped metal sheet, a Cu fan-shaped metal sheet and a Zn fan-shaped metal sheet;

[0035] Assemble the Co fan-shaped metal sheet, Ni fan-shaped metal sheet, Cu fan-shaped metal sheet and Zn fan-shaped metal sheet into a cylindrical target to obtain a multi-metal mixed target;

[0036] Under vacuum conditions, the multi-metal mixed target is used as a target material, and the silicon substrate is subjected to radio frequency magnetron sputtering to obtain the high-entropy oxide thin film.

[0037] In the present invention, unless otherwise specified, the raw materials used are commercially available products in the art.

[0038] In the present invention, Co metal...

Embodiment 1

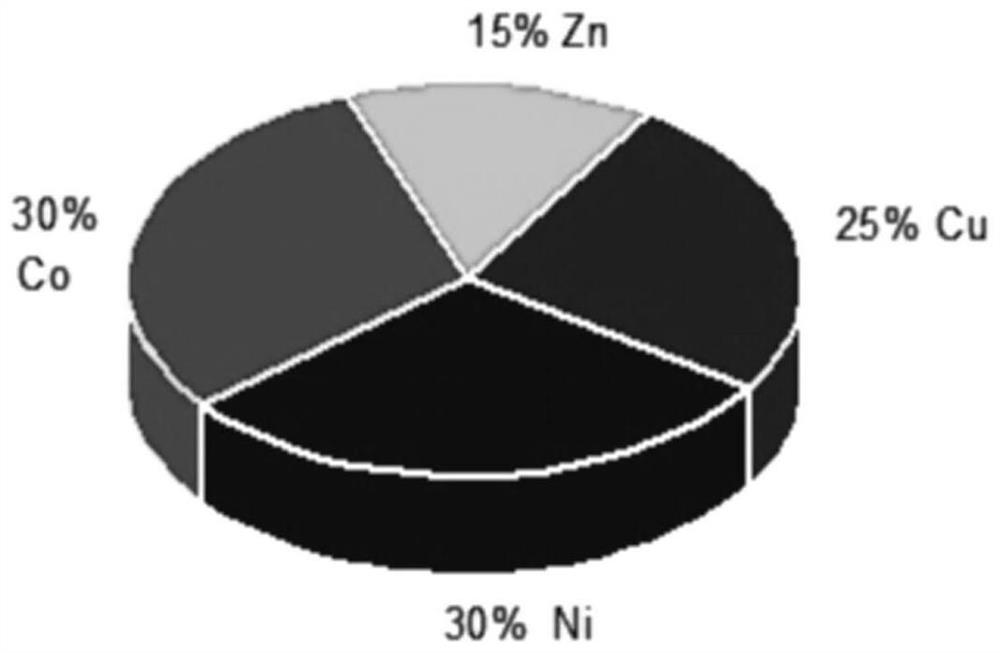

[0066] Step S1: firstly take a metal plate (Co, Ni, Cu, Zn) with a purity higher than 99.90%, and use a wire cutting machine to cut the plate into a sector with a diameter of 60mm, a thickness of 5mm, and different radians. The area percentage of the sector is as follows: 15% Zn fan-shaped metal sheet, 25% Cu fan-shaped metal sheet, 30% Co fan-shaped metal sheet, 30% Ni fan-shaped metal sheet;

[0067] Step S2: Ultrasonic cleaning each fan-shaped metal sheet with alcohol, acetone, and deionized water for 5 minutes respectively; assemble each fan-shaped metal sheet into a cylindrical target, and fix it on the target base with a fixture to obtain a multi-metal mixed target;

[0068] Step S3: ultrasonically cleaning the monocrystalline silicon (100) base material with alcohol, acetone, and deionized water for 5 minutes in sequence;

[0069] Step S4: Load the cleaned monocrystalline silicon (100) base material in the radio frequency magnetron sputtering vacuum chamber, close the ...

Embodiment 2

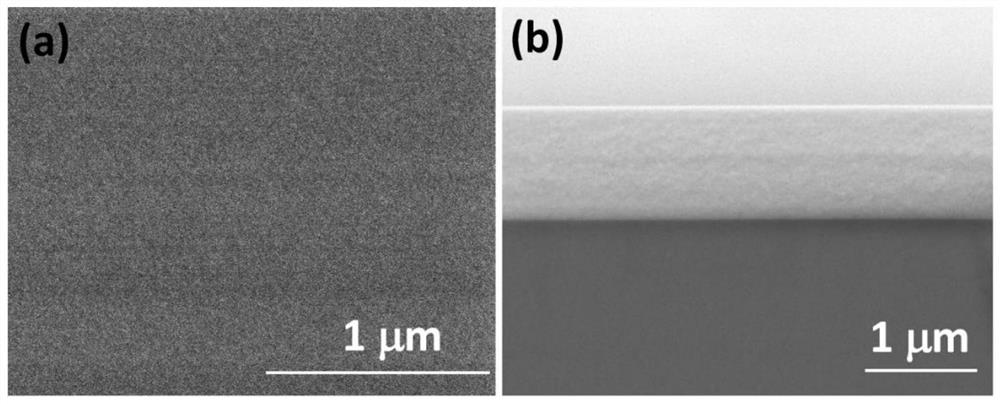

[0084] Same as Example 1, the only difference is that the sputtering time is 3h again, the thickness of the obtained high-entropy oxide film is 1.2μm, the grain size is 10-20nm, and the saturation magnetization at room temperature is 120emu / cm 3 , The coercive force is 18Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com