Electrolytic additive component for electrolytic copper by recycling alkaline etching solution

A technology of electrolytic copper and additives, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of low density of electrolytic copper, low texture of electrolytic copper plate, low quality and purity, etc. Guaranteed etching rate and etching factor, the effect of high quality and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

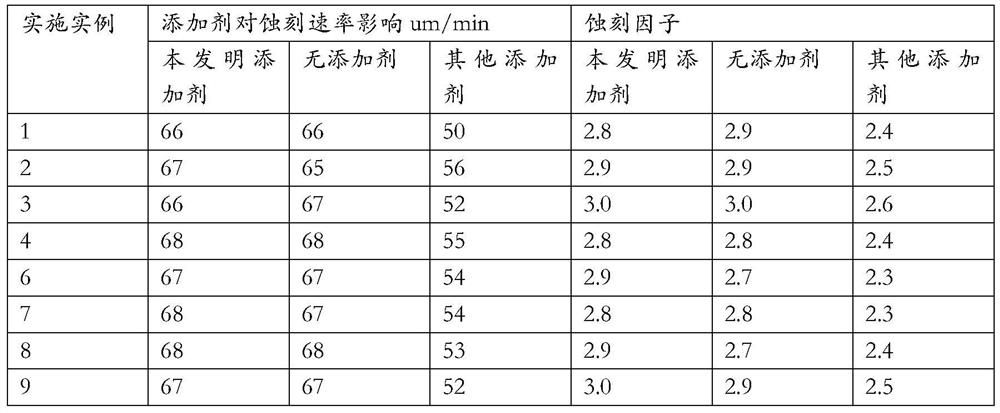

Examples

Embodiment Construction

[0012] The raw materials used in this application all meet the international industrialized raw material standards, so the source of a single raw material is not indicated in this application. This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art are after reading Modifications without creative contribution can be made to this embodiment as required after this description, but as long as they are within the scope of the claims of the present invention, they are all protected by the patent law.

[0013] An electrolytic additive component of an alkaline etching solution that recycles and utilizes electrolytic copper, and is prepared from raw materials in the following mass ratio: PEG-8000: SPS: Basic Bright Yellow: Copper Sulfate: Water = 2500: 40: 15: 10: 22500 .

[0014] The preparation process is:

[0015] (1) Use a 10L measuring cup to add 10 liters of water, then add 2.5 kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com