Heat transfer printing disperse color paste and preparation method thereof, and heat transfer printing ink and preparation method thereof

A technology of thermal transfer printing and color paste, applied in transfer printing, dyeing, printing, etc., can solve the problems of operator and environmental damage, thermal transfer ink is easy to age, and a large amount of white smoke is easy to produce, so as to improve grinding Efficiency, good nozzle moisturizing performance, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the present invention, the preparation method of the dispersant preferably comprises the following steps:

[0029] The dispersant is obtained by mixing benzyl methacrylate, methacrylic acid salt, an initiator and a solvent, and reacting under an inert atmosphere.

[0030] In the present invention, the operating process of the reaction is specifically preferably:

[0031] Mix benzyl methacrylate with the first part of organic solvent to obtain premix A; mix potassium methacrylate, the first part of water and the second part of organic solvent to obtain premix B; mix the first part of initiator and the third part Mixing organic solvents to obtain premix C; mixing the remaining initiator with the fourth part of organic solvent to obtain premix D;

[0032] Add the remaining water and the remaining organic solvent into the reaction device, and then pass inert gas, then add the premix A, premix B and premix C into the reaction device for reaction, after 3-4 hours of react...

Embodiment 1~4

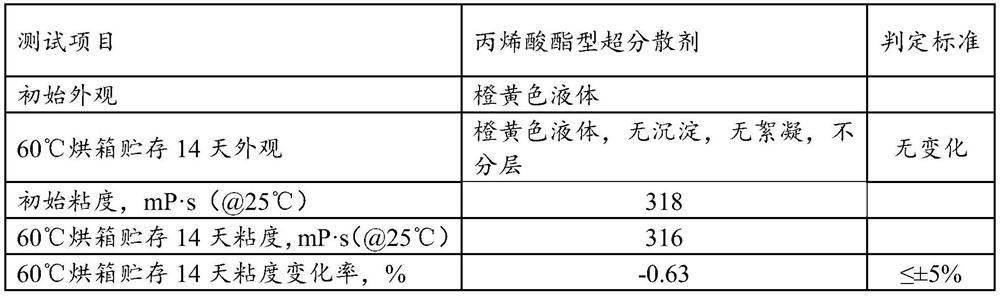

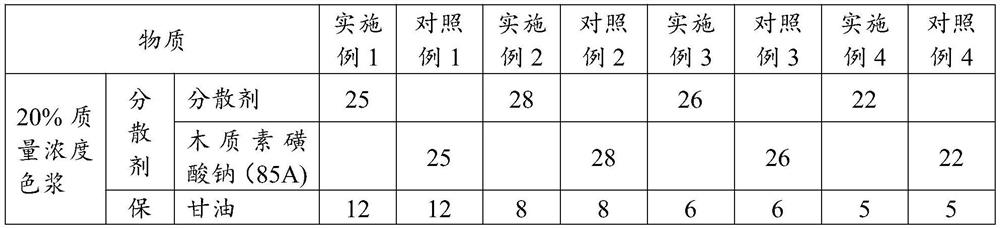

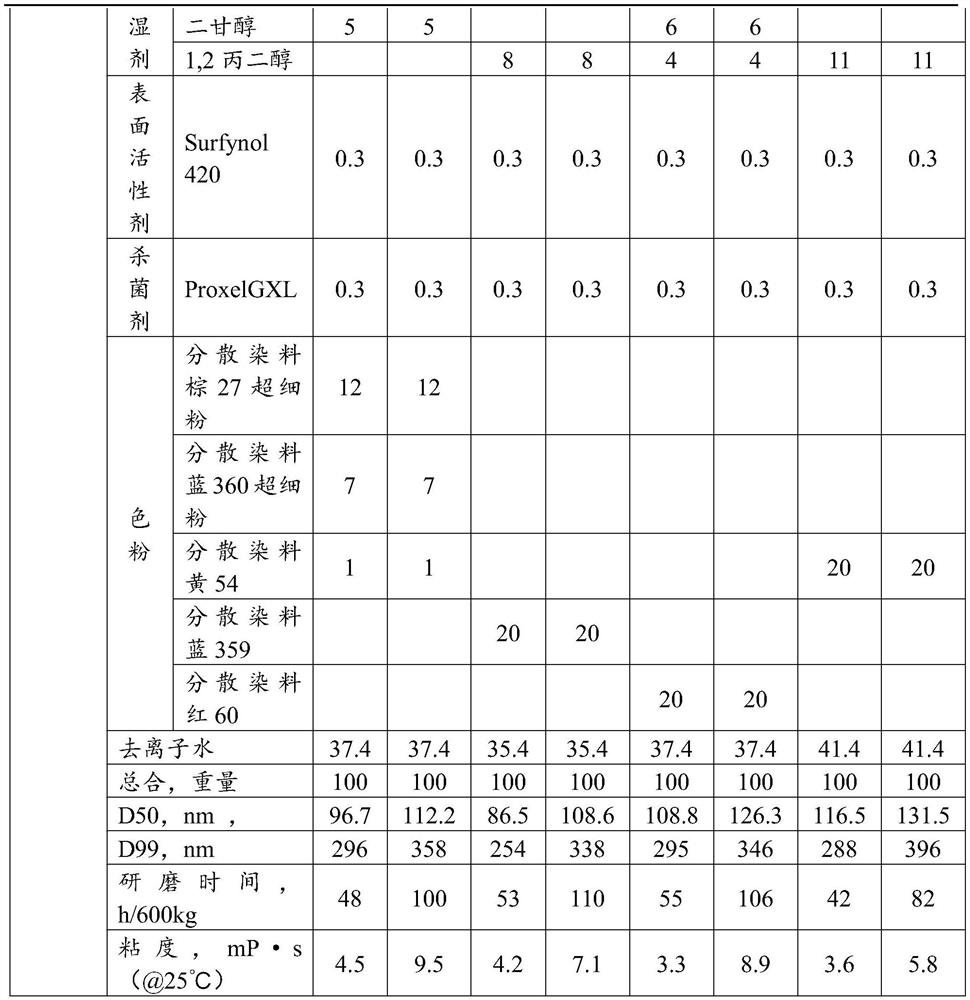

[0066] The thermal transfer disperse color paste was prepared by using the above dispersant, and the mass fraction of the thermal transfer disperse dye in the color paste was 20%. The formulas of the thermal transfer disperse color paste in Examples 1-4 are shown in Table 2.

[0067] The preparation method of thermal transfer dispersion color paste is as follows: mix the raw materials to obtain the color paste dispersion liquid, inject the color paste dispersion liquid into a ceramic sand mill for grinding, use zirconium beads as abrasive particles in the grinding, and the particle size of the grinding particles is 0.05 ~0.2μm, the D of the milled paste 50 Controlled at 50~150nm, D 99 The particle size is controlled at <400nm. After reaching this standard, the material is filtered to obtain thermal transfer dispersion color paste. The specific particle size of the color paste and the grinding time required to reach the grinding end point are shown in Table 2.

Embodiment 5~8

[0075] The thermal transfer printing inks prepared in Examples 1-4 were respectively used to prepare thermal transfer printing inks, and the formulations of the thermal transfer printing inks prepared in Examples 5-8 are shown in Table 3.

[0076] The preparation method of thermal transfer printing ink is as follows: add deionized water, humectant, surfactant, defoamer, and bactericide in order, stir at room temperature 200rpm for 15 minutes, mix well, add thermal transfer dispersion color paste, and stir for 1 hour. Filter through a PVDF membrane with a pore size of 1.0 μm to obtain thermal transfer ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com