A kind of copper film catalyst for cvd growth graphene and its application

A graphene film, graphene technology, applied in the direction of graphene, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low uniformity and crystallization performance, affecting graphene performance, etc. problem, to achieve the effect of high crystallinity, simple and easy preparation process, and easy to promote large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

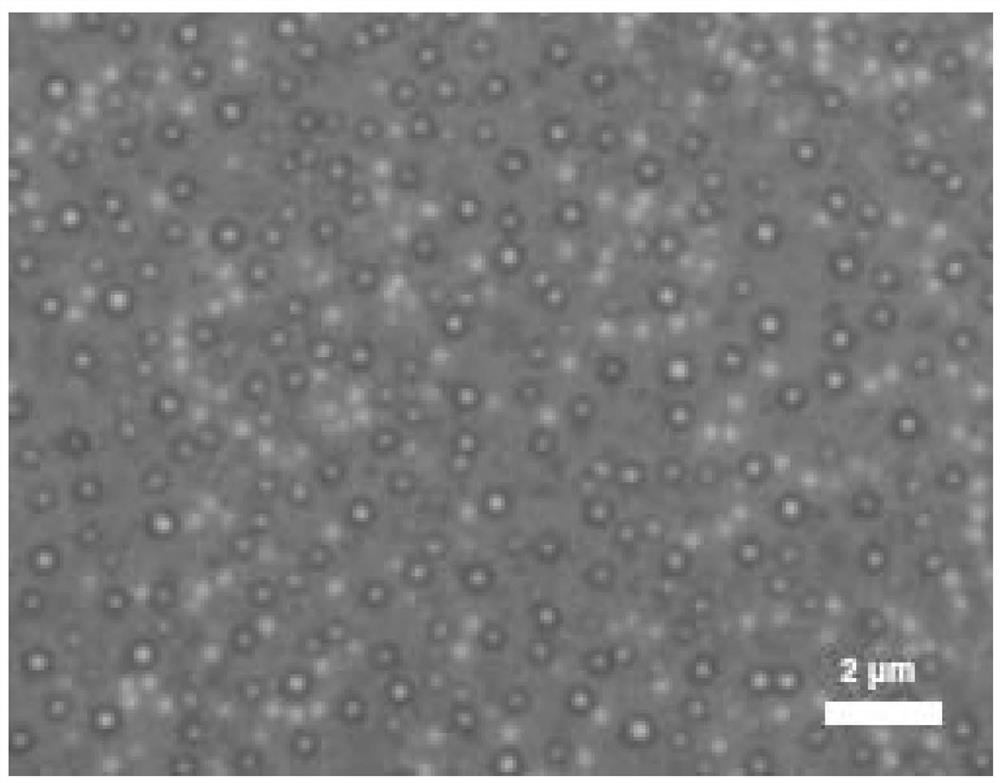

[0042] The quartz pieces were sonicated with acetone, anhydrous ethanol, and deionized water for 15 minutes each, and then with CF 4 Plasma surface treatment is performed on the quartz plate. First, the quartz plate is placed in a plasma treatment instrument (frequency is 13.56MHz), CF 4 The purity is 99.9%, the background vacuum is 1.0Pa, the power is 150W, and the time is 15min. 2 protection for 5min;

[0043] The quartz wafer is coated by sputtering coating method; the steps and parameters of the sputtering coating method include: placing the pretreated quartz wafer into a magnetron sputtering chamber, and the background vacuum is 7×10 -5 Pa, sputtering power 100W, sputtering pressure 0.1Pa, Ar100sccm, and sputtering time 10min. The thickness of the copper film in the obtained copper film catalyst is 50 nm;

[0044] Then the obtained copper film catalyst was put into the chemical vapor deposition equipment, filled with Ar=200sccm; then the temperature was raised, and whe...

Embodiment 2

[0046] The quartz pieces were sonicated with acetone, anhydrous ethanol, and deionized water for 15 minutes each, and then with CF 4 Plasma surface treatment is performed on the quartz plate. First, the quartz plate is placed in a plasma treatment instrument (frequency is 13.56MHz), CF 4 The purity is 99.9%, the background vacuum is 1.0Pa, the power is 150W, and the time is 15min. 2 protection for 5min;

[0047] The copper film is coated on the quartz sheet by the method of thermal evaporation coating; the steps and parameters of the thermal evaporation include: putting the quartz sheet into a vacuum coating machine, closing each valve for vacuum treatment, the purity of the copper sheet is 99.999%, and the vacuum degree is greater than 1×10 -3 Pa, the substrate temperature is 250°C; the thickness of the copper film in the obtained copper film catalyst is 50 nm;

[0048] Then put the copper film catalyst into the chemical vapor deposition equipment, and fill it with Ar=200s...

Embodiment 3

[0051] The quartz pieces were sonicated with acetone, anhydrous ethanol, and deionized water for 15 minutes each, and then with CF 4 Plasma surface treatment is performed on the quartz plate. First, the quartz plate is placed in a plasma treatment instrument (frequency is 13.56MHz), CF 4 The purity is 99.9%, the background vacuum is 3.0Pa, the power is 150W, and the time is 15min. 2 protection for 5min;

[0052] The quartz wafer is coated by sputtering coating method; the steps and parameters of the sputtering coating method include: placing the pretreated quartz wafer into a magnetron sputtering chamber, and the background vacuum is 7×10 -5 Pa, sputtering power 100W, sputtering pressure 0.1Pa, Ar100sccm, sputtering time 20min;

[0053] The thickness of the copper film in the copper film catalyst in Example 3 was 100 nm. The obtained copper membrane catalyst was used for in-situ growth of graphene, and the preparation process was the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com