Low-formaldehyde high-quality solid wood composite floor and processing technology

A technology for solid wood composite flooring and processing technology, which is used in wood processing appliances, plywood presses, and the joining of wooden veneers. Promotion and other issues to achieve the effect of improving gluing efficiency, improving production efficiency and avoiding formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

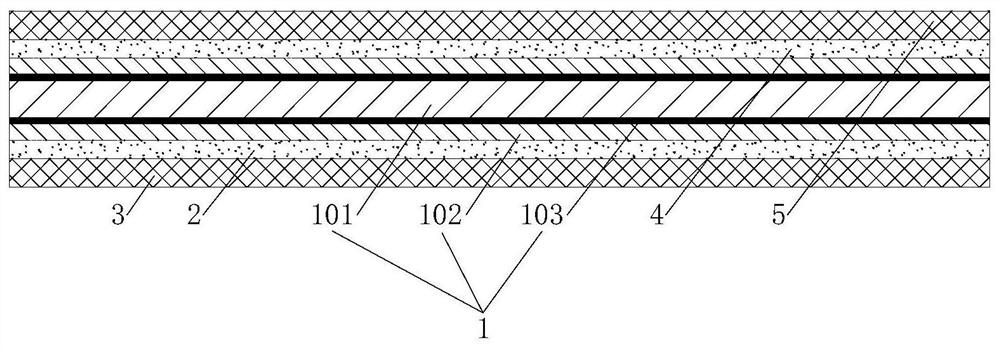

[0035] Example 1. A low-aldehyde high-quality engineered wood flooring consisting of figure 1 As shown, it includes a substrate 1, the back of the substrate 1 is connected with a backboard 3 through a first thermosetting adhesive film 2, and the front of the substrate 1 is connected with a panel 5 through a second thermosetting adhesive film 4; the substrate 1 includes a core The board 101 and the front and back of the core board 101 are provided with veneers 102 .

[0036] The front and back of the core board 101 are connected to the veneer 102 through the MDI formaldehyde-free adhesive layer 103 .

[0037] The thickness of the core board 101 is 6-8 mm, and the thickness of the single board 102 is 2-3 mm.

[0038] The thickness of the back plate 3 is 0.7-1 mm, and the thickness of the panel 5 is 1-2.5 mm.

[0039] The wood grain directions of the core board 101 , the face plate 5 and the back board 3 are all longitudinal (consistent with the length direction of the floor),...

Embodiment 2

[0049] Example 2. A low-aldehyde high-quality engineered wood flooring consisting of figure 1 As shown, it includes a substrate 1, the back of the substrate 1 is connected with a backboard 3 through a first thermosetting adhesive film 2, and the front of the substrate 1 is connected with a panel 5 through a second thermosetting adhesive film 4; the substrate 1 includes a core Board 101, the front and back sides of core board 101 are provided with veneer 102; the melting point of the first thermosetting adhesive film paper 2 and the second thermosetting adhesive film paper 4 are both 25-30°C, and the curing temperature is 108-116°C .

[0050] The front and back of the core board 101 are connected to the veneer 102 through the MDI formaldehyde-free adhesive layer 103 .

[0051] The thickness of the core board 101 is 6-8 mm, and the thickness of the single board 102 is 2-3 mm.

[0052] The thickness of the back plate 3 is 0.7-1 mm, and the thickness of the panel 5 is 1-2.5 mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com