Preparation method of styrene oxide

A technology of ethylene oxide and styrene, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. problems, to achieve high reactivity, simplify the process flow, reduce the effect of the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]1) Preparation of modified molybdenum lactate catalyst: Dissolve 25.8g (0.2mol) n-octylamine in 103.9g (120ml) toluene, then add 14.3g (0.1mol) dichloroethyl ether, reflux at 75°C for 5h; in the above solution Add 18g (0.2mol) of lactic acid and 0.33g (1.9mmol) of p-toluenesulfonic acid, continue to react at 110°C for 12h, and filter while hot; The molybdenum oxide was continuously reacted at 200° C. for 24 hours, and the modified molybdenum lactate catalyst was obtained by filtration, and the molybdenum content was 3.2 wt % as measured by ICP.

[0040] 2) Synthesis of styrene oxide: Dissolve 31.2g (0.3mol) styrene in 259.8g (300ml) toluene, add 0.035g (12umol) modified molybdenum lactate catalyst, heat up to 70°C under stirring, and continuously add 11.3 g (0.1mol) 30% hydrogen peroxide aqueous solution, continue to maintain the temperature after the addition, and take samples at intervals during the heat preservation process for GC analysis. After 6 hours of normal pre...

Embodiment 2

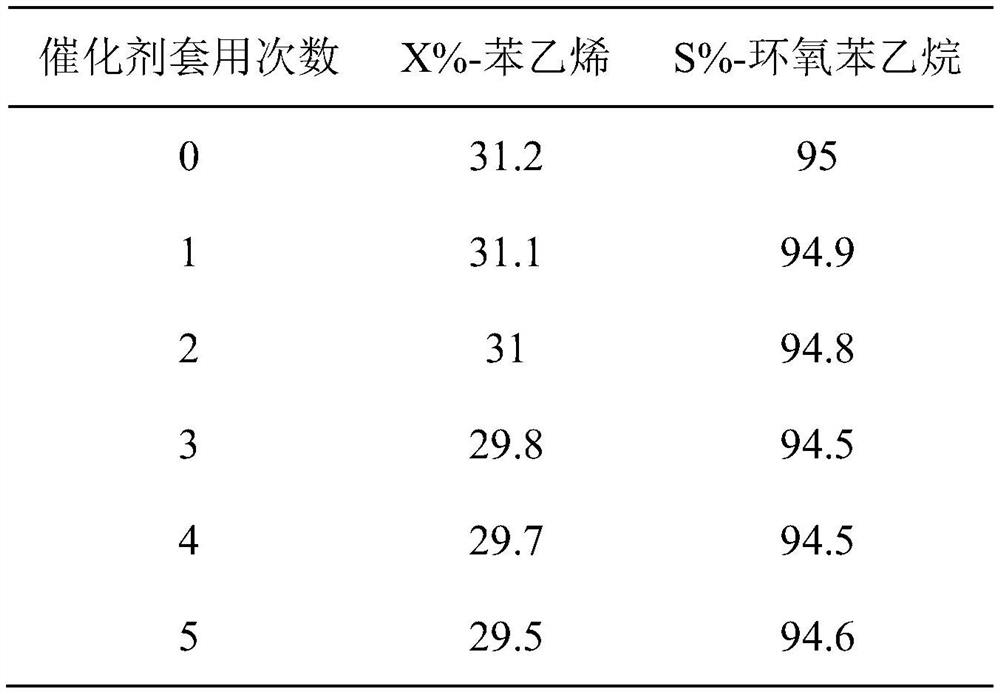

[0042] The fresh molybdenum lactate catalyst is replaced by a reclaimed catalyst, and other reaction conditions are the same as in Example 1, and the reaction results are as follows.

[0043]

Embodiment 3

[0045] 1) Preparation of modified molybdenum lactate catalyst: Dissolve 55.6g (0.3mol) dodecylamine in 433g (500ml) toluene, then add 14.3g (0.1mol) dichloroethyl ether, reflux at 90°C for 8h; add 19.8g (0.22mol) of lactic acid and 2.8g (16mmol) of p-toluenesulfonic acid, continued to react at 130°C for 16h, filtered while hot; the filter cake was added to 129.9g (150ml) of toluene, and 1.7g (0.012mol) of trioxide The molybdenum was continuously reacted at 220°C for 36 hours, and the modified molybdenum lactate catalyst was obtained by filtration, and the molybdenum content was 2.6wt% as measured by ICP.

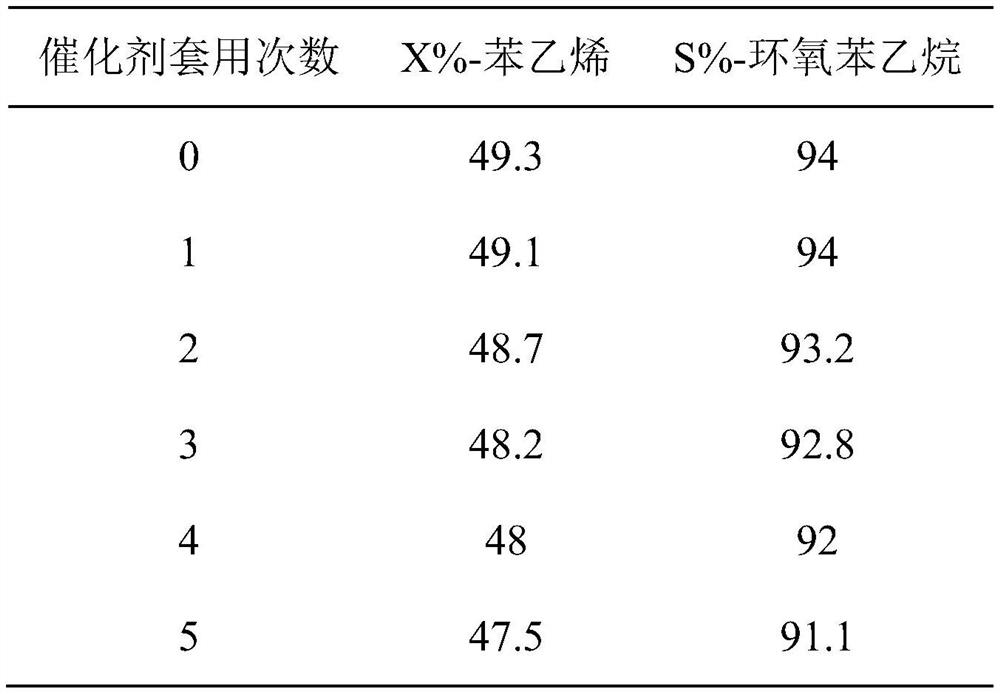

[0046] 2) Synthesis of styrene oxide: Dissolve 12.5g (0.12mol) styrene in 103.9g (120ml) toluene, add 0.065g (18umol) modified molybdenum lactate catalyst, heat up to 60°C under stirring, and continuously add 11.3 g (0.1mol) 30% hydrogen peroxide aqueous solution, continue to maintain the temperature after the addition, and take samples at intervals during the heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com