A kind of preparation method of superhydrophobic low infrared emissivity coating

A low-infrared emission, super-hydrophobic technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of lack of super-hydrophobicity and self-cleaning properties, and achieve good infrared stealth effect, excellent adhesion and low gloss performance. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

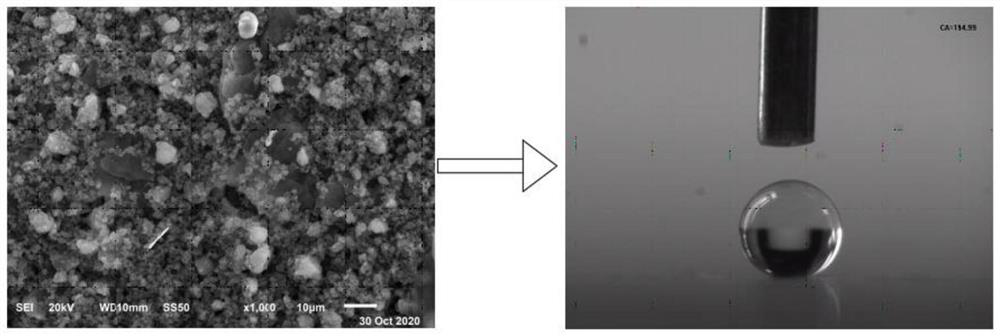

[0024] see Figure 1-2 , the embodiment of the present invention provides a technical solution: a method for preparing a superhydrophobic low infrared emissivity coating, the specific operation steps are as follows:

[0025] S1, use standard tin plate, aluminum alloy plate and titanium alloy plate as the substrate, polish the substrate with sandpaper to make the substrate have a roughness of 3-10 μm, rinse it with tap water and dry it in an oven at 80°C for 30 minutes, then use a piece of alcohol dipped in alcohol Wipe the substrate clean with a cotton cloth for later use;

[0026] S2, HCSO and PU are fully mixed according to the mass ratio of 1:9 to 3:7 to obtain blended modified PU, and then HCSO modified PU is used as a binder to prepare a coating, and polyether polyol is used as a curing agent. agent, the dosage is 25% of the quality of the above-mentioned modified resin;

[0027] S3, flaky Al powder and nano-SiO 2 The mass ratio is 5.5:4.5~6.5:3.5, and an appropriate a...

Embodiment 1

[0035] Mix HCSO and PU at a mass ratio of 1:9 to obtain blended modified PU, then use HCSO modified PU as a binder to prepare a coating, and use polyether polyol as a curing agent, the amount of which is the above modification 25% of the mass of permanent resin;

[0036] Flaky Al powder and nano-SiO 2 The mass ratio is 6.5:3.5, and an appropriate amount of HCSO modified PU and functional filler (flaky Al powder + nano-SiO 2 );

[0037] In the plastic cup, add absolute ethanol as a diluent, the weight of which is 20% of the mass of HCSO modified PU, and use a glass rod to fully stir to make it evenly dispersed until no obvious particles can be seen in the coating;

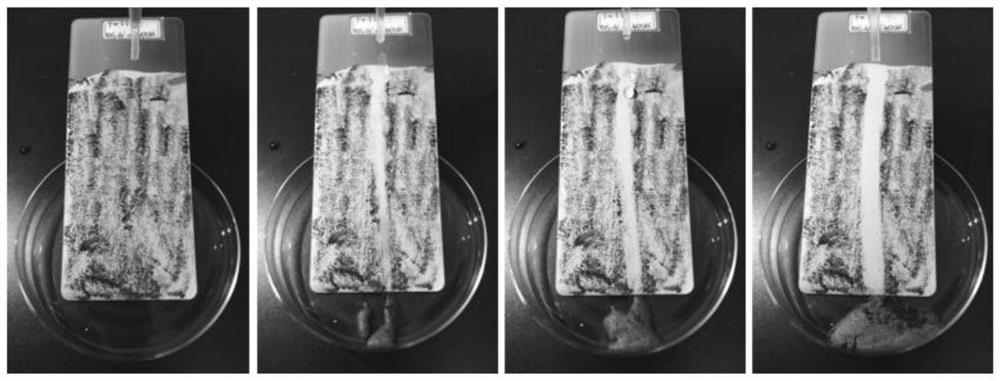

[0038] Use ultrasonic waves with a frequency of 25KHz to disperse the paint further ultrasonically for 10 minutes to further disperse the paint evenly, and then add a small amount of absolute ethanol to adjust the viscosity of the paint to an appropriate range until it can flow continuously downward in a straight li...

Embodiment 2

[0042] Mix HCSO and PU at a mass ratio of 2:8 to obtain blended modified PU, then use HCSO modified PU as a binder to prepare a coating, and use polyether polyol as a curing agent, the amount of which is the above modified 25% of the mass of permanent resin;

[0043] Flaky Al powder and nano-SiO 2 The mass ratio is 5.5:4.5, and an appropriate amount of HCSO modified PU and functional filler (flaky Al powder + nano-SiO 2 );

[0044] In the plastic cup, add absolute ethanol as a diluent, the weight of which is 15% of the mass of HCSO modified PU, and use a glass rod to fully stir to make it evenly dispersed until no obvious particles can be seen in the coating;

[0045] Use ultrasonic waves with a frequency of 25KHz to disperse the paint further ultrasonically for 10 minutes to further disperse the paint evenly, and then add a small amount of absolute ethanol to adjust the viscosity of the paint to an appropriate range until it can flow continuously downward in a straight line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com