High-pressure jet grouting pile construction method for road foundation

A technology of high-pressure rotary grouting piles and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, soil protection, etc., can solve the problems of poor shape controllability, easy pollution of the environment, poor erosion resistance, etc., and achieve slurry concentration and material Wide, durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing and embodiment:

[0025] Technical solution of the present invention is as follows:

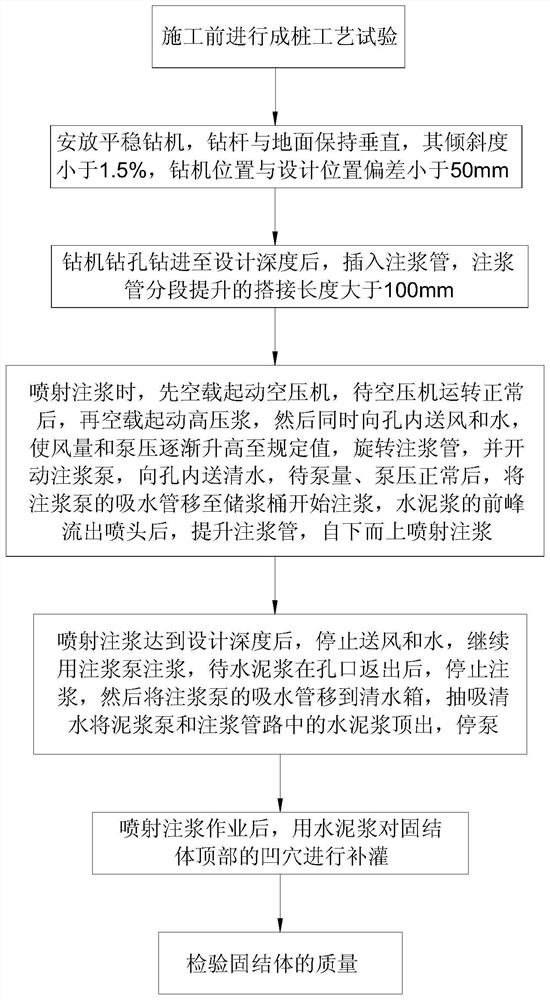

[0026] Such as figure 1 Shown, a kind of high-pressure rotary grouting pile construction method of road foundation, comprises the following steps:

[0027] (1) Piling process test shall be carried out before construction.

[0028] (2) Place the drilling rig stably, keep the drill pipe vertical to the ground, its inclination is less than 1.5%, and the deviation between the position of the drilling rig and the design position is less than 50mm.

[0029] (3) After the drilling rig drills the hole to the design depth, insert the grouting pipe, and the overlapping length of the grouting pipe is greater than 100mm.

[0030] (4) When spraying grouting, first start the air compressor with no load, and then start the high-pressure grout with no load after the air compressor runs normally, and then send ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com