Preparation method of nano bismuth/graphene composite material and application of nano bismuth/graphene composite material in MALDI-MS

A composite material and nanomaterial technology, applied in the field of preparation of nano-bismuth/graphene composite materials, can solve the problems of uneven crystallization of matrix and sample, increased identification difficulty, poor reproducibility, etc., and achieves overcoming matrix interference and high stability. , the effect of narrow band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

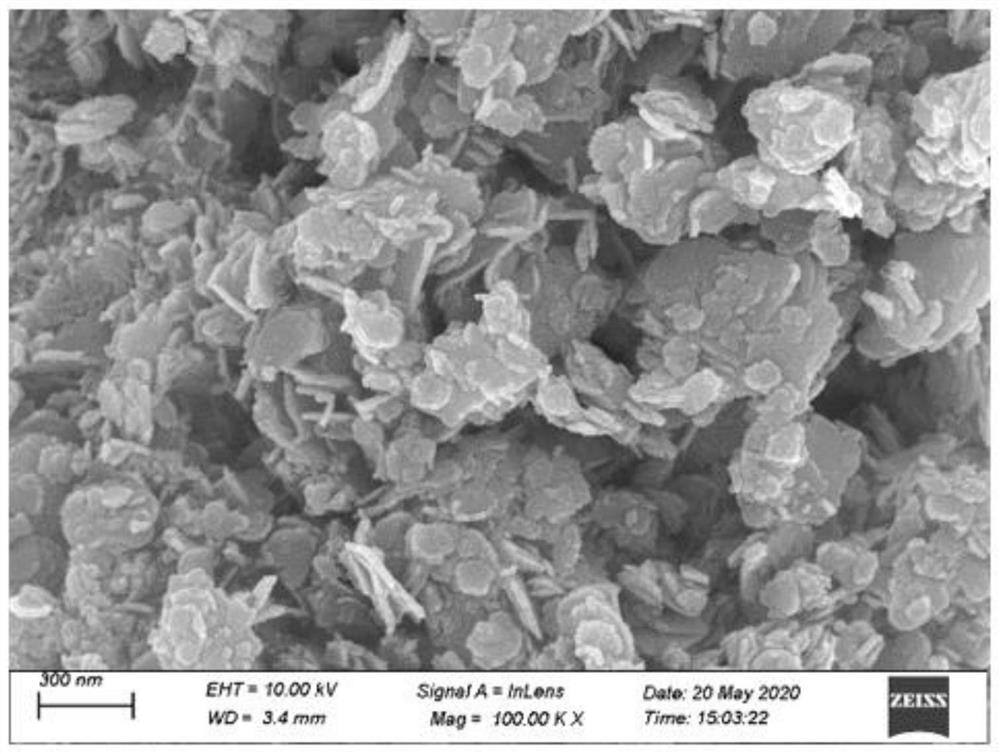

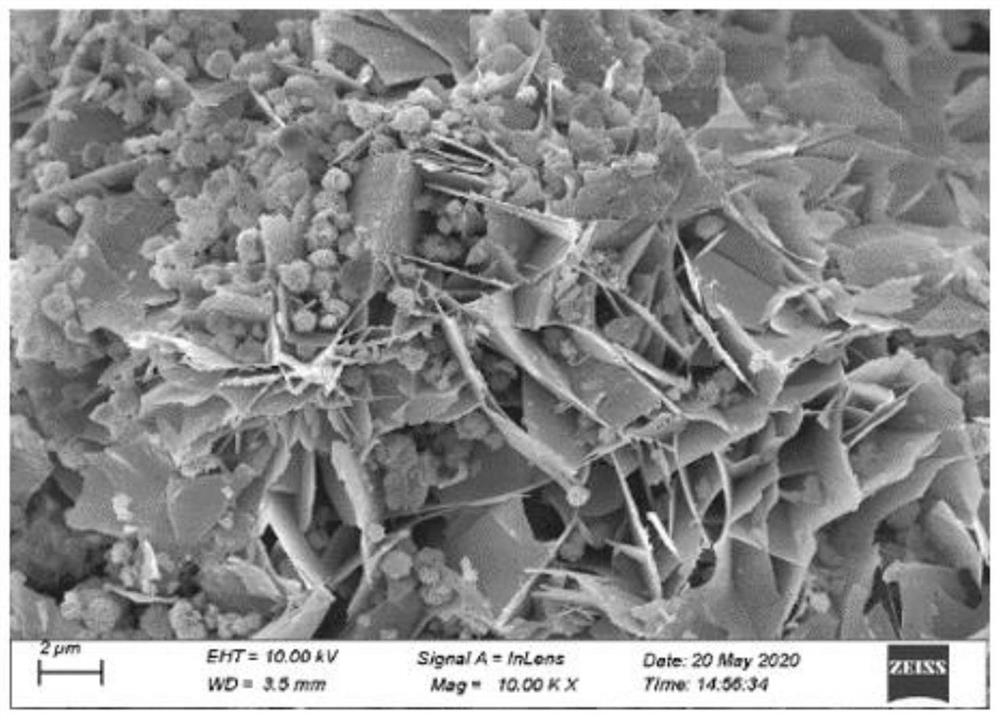

[0029] A preparation method of nano-bismuth / graphene composite material, comprising the following steps:

[0030] S01. Prepare GO, configure a GO aqueous solution with a concentration of 0.5-1.5 mg / mL;

[0031] S02. Add bismuth salt in step S01, the concentration of bismuth salt is 30mM, stir for 20-40min, and adjust the pH of the solution to be 9-10;

[0032] S03. Place the solution treated in step S02 in a reaction kettle to react at a temperature of 180° C. for 8 to 12 hours;

[0033] S04. Wash the solid obtained in step S03 with ethanol and water for several times, and then vacuum-dry to obtain a bismuth / graphene composite material.

[0034] The bismuth / graphene composite material obtained by the preparation method of the nano-bismuth / graphene composite material.

[0035] Preparation of bismuth oxide nanomaterials: disperse bismuth-containing salts in organic solvents, and obtain required bismuth nanomaterials after high temperature and high pressure solvothermal reactio...

Embodiment 2

[0045]Bismuth oxide nanomaterials and bismuth / graphene composite materials are the same as in Example 1.

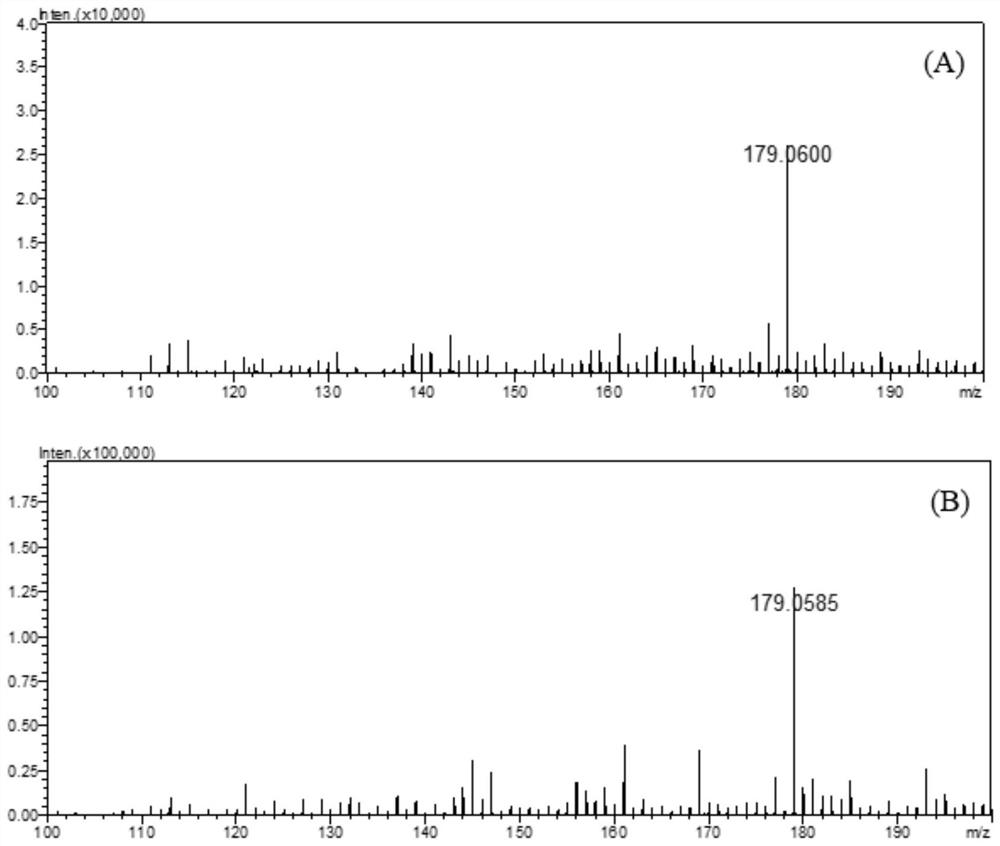

[0046] Bismuth-based nanomaterials are used as substrates for matrix-assisted laser desorption ionization time-of-flight mass spectrometry detection. The specific experimental process is as follows:

[0047] 1. Prepare an organic suspension solution of 2.0mg / mL bismuth-based nanomaterials as matrix solution;

[0048] 2. Ultrasonic the above system at room temperature for 1-2 minutes to form a uniform dispersion suspension system;

[0049] 3. Configure 10mM five kinds of mixed amino acid solutions as the sample solution to be tested, the concentration is 10mM, and the specific amino acids are Asp, Glu, His, Arg, and Try.

[0050] 4. Drop the nano-suspension onto the MALDI MS metal target plate, and form a uniform matrix layer after the solution is dried.

[0051] 5. Add the sample solution dropwise to the surface of the dried nanomaterial described in step 3.

[0052] 6...

Embodiment 3

[0055] Bismuth oxide nanomaterials and bismuth / graphene composite materials are the same as in Example 1.

[0056] Bismuth-based nanomaterials are used as substrates for matrix-assisted laser desorption ionization time-of-flight mass spectrometry detection. The specific experimental process is as follows:

[0057] 1. Prepare an organic suspension solution of 2.0mg / mL bismuth-based nanomaterials as matrix solution;

[0058] 2. Ultrasonic the above system at room temperature for 1-2 minutes to form a uniform dispersion suspension system;

[0059] 3. Configure 200mM 5 kinds of mixed fatty acid solutions as the sample solution to be tested, the specific fatty acids are C12:0, C14:0, C16:0, C18:0, C20:0

[0060] 4. Drop the nano-suspension onto the MALDI MS metal target plate, and form a uniform matrix layer after the solution is dried.

[0061] 5. Add the sample solution dropwise to the surface of the dried nanomaterial described in step 3.

[0062] 6. The dried spots were subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com