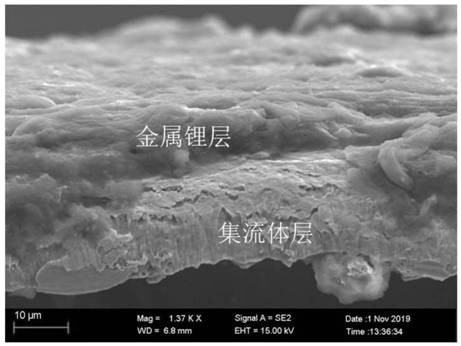

Ultrathin metal lithium electrode, preparation method thereof, and application of ultrathin metal lithium electrode as negative electrode of primary lithium battery

An ultra-thin metal, lithium electrode technology, applied in primary batteries, electrode carriers/current collectors, battery electrodes, etc., can solve the problem of low energy density of primary lithium batteries, achieve industrialization and practicality, huge application market, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

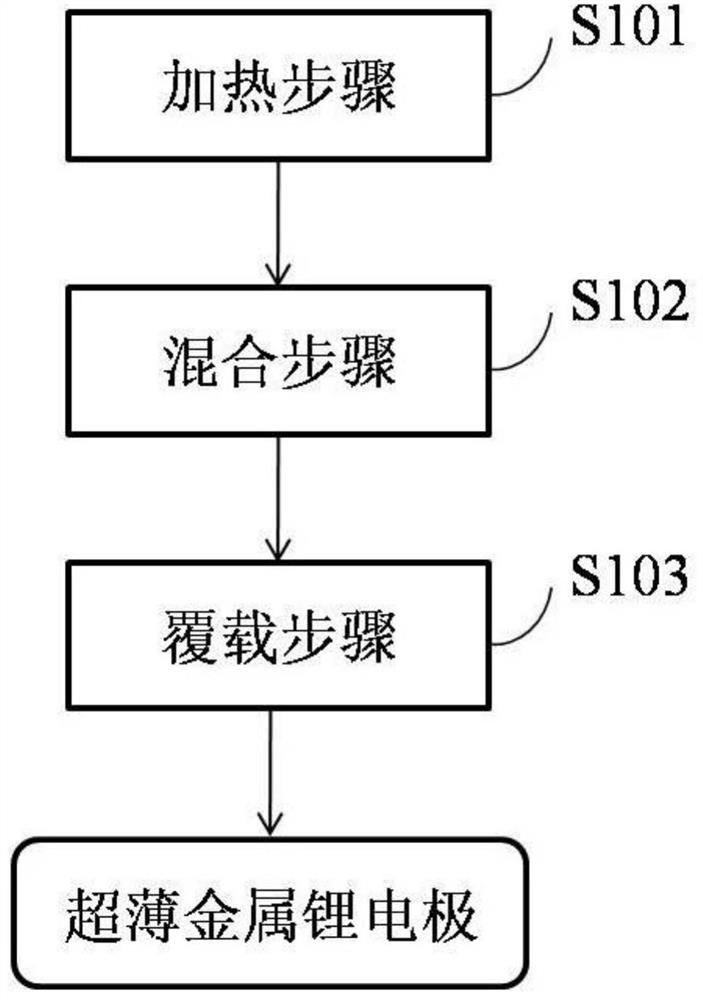

[0032] This embodiment provides a preparation method of the ultra-thin metal lithium electrode of the present invention, such as figure 1 shown, including steps:

[0033] Heating step S101: heating and melting metal lithium or lithium alloy in an inert gas environment to obtain liquid metal lithium;

[0034] Mixing step S102: adding additional components into the liquid lithium metal, mixing and dispersing to obtain a mixed lithium slurry;

[0035] Covering step S103: coating the mixed lithium slurry on the current collector layer to form a thin film layer, and after the thin film layer is cooled and solidified, an ultra-thin metal lithium electrode is obtained.

Embodiment 2

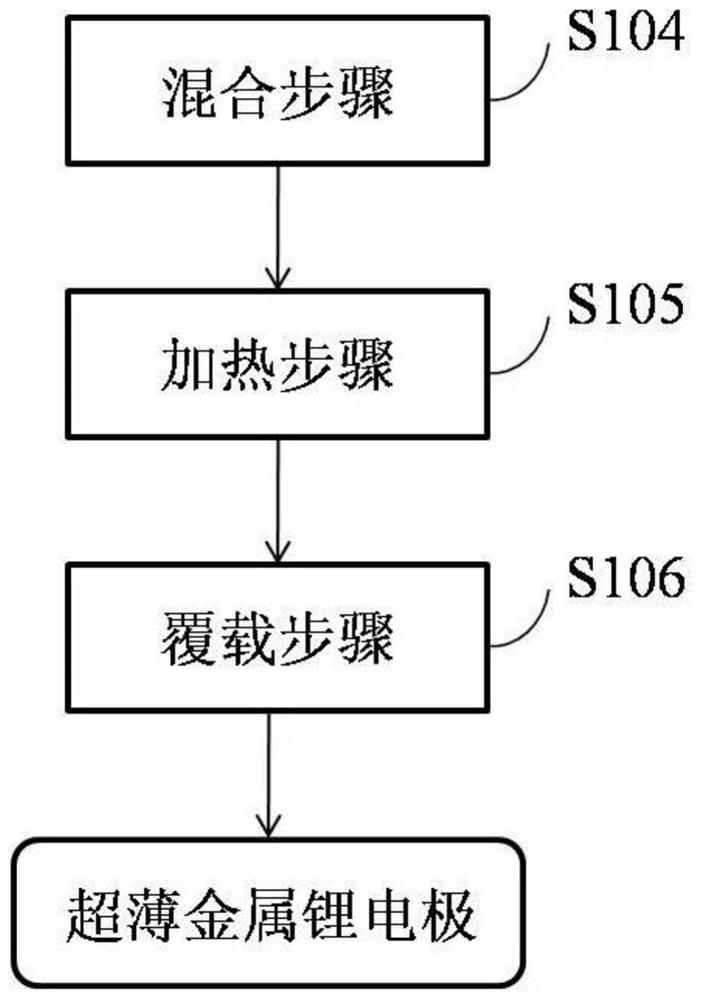

[0037] This embodiment provides another embodiment of the preparation method of the ultra-thin metal lithium electrode of the present invention, such as figure 2 shown, including steps:

[0038] Mixing step S104: in an inert gas environment, physically mix the metal lithium or lithium alloy with the added components to obtain a mixture;

[0039] Heating step S105: heating the mixture until the metal lithium is melted to obtain a mixed lithium slurry;

[0040]Covering step S106: coating the mixed lithium slurry on the current collector layer to form a thin film layer, and after the thin film layer is cooled and solidified, an ultra-thin metal lithium electrode is obtained.

[0041] In Examples 1 and 2, the lithium alloy contains alloying elements that reduce the surface tension of liquid metal lithium, and the alloying elements include: Mg, Al, In, Zn, Ag, Ca, Sr, Ba, Sc, Y, Rh, One or more of Ir, Pd, Pt, Au, Cd, Hg, Ga, Tl, Ge, Pb, As, Sb, Bi, B, S, Se or Te. Alloying elem...

Embodiment 3

[0047] This embodiment provides a specific implementation method in Example 1, using the transition metal carbide titanium carbide (Ti) containing the alloying element Mg and the added component -F functional group 3 C 2 F) as an example, specifically illustrate the preparation method of the ultra-thin metal lithium electrode of the present invention, comprising steps:

[0048] Heating step: In an atmosphere of argon (purity greater than 99.999%), add 400 mg of metallic lithium block into a stainless steel pot and heat to 200° C. to melt the metallic lithium block into a liquid state.

[0049] Mixing steps: keep the heating temperature, first add 40mg metal magnesium flakes to the liquid metal lithium, then add 50mg Ti 3 C 2 F, stirring and mixing, the metal magnesium flakes are melted to form a liquid lithium-magnesium alloy, and the stirring is continued for about 30 minutes to make the Ti 3 C 2 F is evenly dispersed to obtain a gel-state mixed lithium slurry;

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com