A kind of nickel-manganese-titanium composite material and its preparation method and application

A composite material, nickel-manganese technology, used in positive electrodes, active material electrodes, structural parts, etc., can solve the problems of poor cathode material capacity and cycle stability, achieve high structural stability and electrochemical performance, and improve electrochemical cycles. The effect of performance and appearance is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

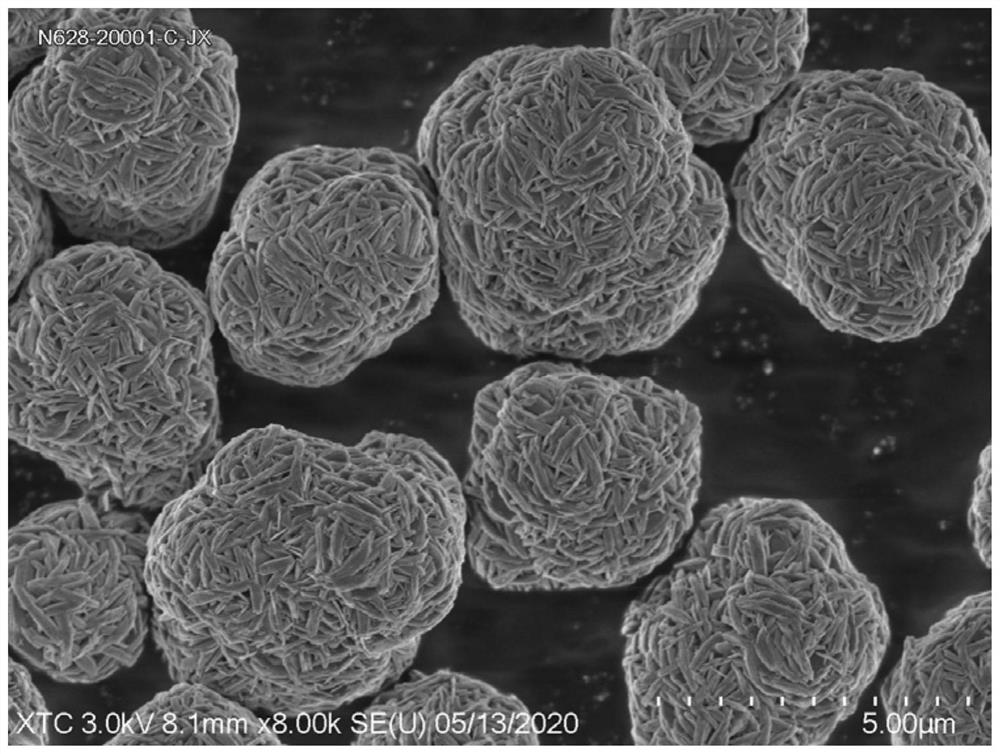

[0060] S1, be 83:17 by the mol ratio of Ni:Mn to take by weighing nickel sulfate and manganese sulfate and be made into the mixed solution of 1mol / L, this mixed solution and the ammonia solution (complexing agent) of 2mol / L, the mixed solution of 2mol / L Aqueous sodium hydroxide solution (precipitating agent) was added to the reaction kettle, and the reaction was allowed to stand for 4 hours under the conditions of a water bath temperature of 55°C and a pH value of 11.00, to obtain a nickel-manganese hydroxide precursor.

[0061] S2, place the nickel-manganese hydroxide precursor in a 2mol / L ammonia solution and continue stirring for 30min, then slowly add a 1mol / L tetrabutyl titanate solution and a 2mol / L sodium hydroxide solution, at a temperature of The primary titanium-doped nickel-manganese precipitate was obtained by standing at 60 °C and a pH value of 11.5 for an aging reaction for 3 hours, wherein the molar ratio of titanium ions and nickel-manganese mixed ions added thi...

Embodiment 2

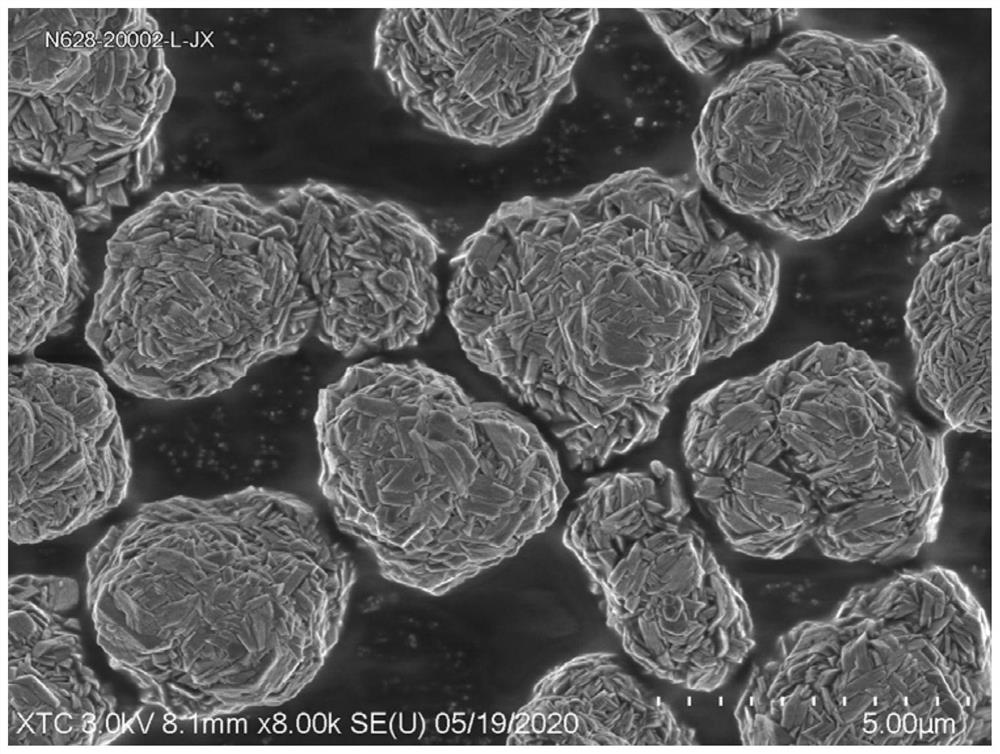

[0067] S1, be 84:16 by the molar ratio of Ni:Mn to take by weighing nickel sulfate and manganese sulfate and be made into the mixed solution of 1mol / L, this mixed solution and the ammonia solution (complexing agent) of 1.5mol / L, 2mol / L The sodium hydroxide aqueous solution (precipitant) was added to the reaction kettle, and the reaction was allowed to stand for 5 hours under the conditions of a water bath temperature of 55 °C and a pH value of 11.00 to obtain a nickel-manganese hydroxide precursor.

[0068] S2. Place the nickel-manganese hydroxide precursor in a 1.5 mol / L ammonia solution and continue stirring for 30 min, and then slowly add a 1 mol / L isobutyl titanate solution and a 2 mol / L sodium hydroxide solution. The reaction was allowed to stand for 4 hours at 50°C and pH 11.5 to obtain primary titanium-doped nickel-manganese precipitates, wherein the molar ratio of titanium ions and nickel-manganese mixed ions added this time was 6:70.

[0069] S3. Place the primary tit...

Embodiment 3

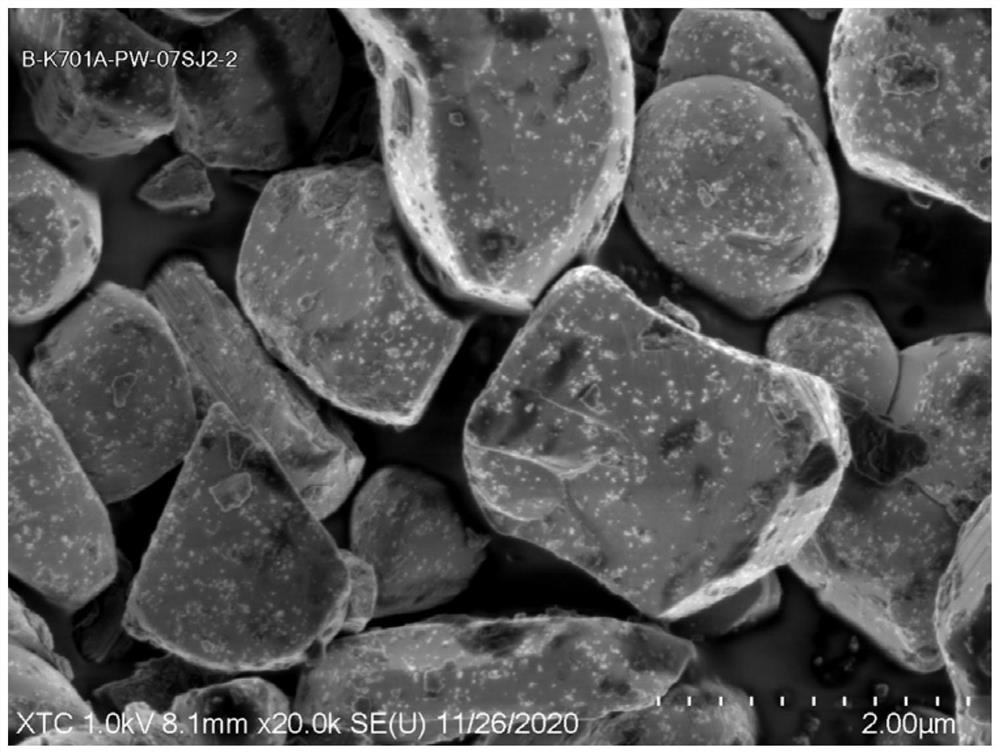

[0074] S1, be 80:20 by the molar ratio of Ni:Mn to take by weighing nickel sulfate and manganese sulfate and be made into the mixed solution of 1.3mol / L, this mixed solution and the ammonia solution (complexing agent) of 1.5mol / L, 2mol / L L potassium hydroxide aqueous solution (precipitating agent) was added to the reaction kettle, and the reaction was allowed to stand for 3.6 hours under the conditions of a water bath temperature of 55 °C and a pH value of 11.00 to obtain a nickel-manganese hydroxide precursor.

[0075] S2, place the nickel-manganese hydroxide precursor in a 1.5 mol / L ammonia solution and continue stirring for 30 min, then add a 1.3 mol / L tetrabutyl titanate solution and a 2 mol / L potassium hydroxide aqueous solution. For 3.8 hours of standing at 55°C and pH value of 11.5 for aging reaction, primary titanium-doped nickel-manganese precipitates were obtained, wherein the molar ratio of titanium ions and nickel-manganese mixed ions added this time was 1:15.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com