N-and-P double-doped carbon fiber-loaded CoP composite catalytic material as well as preparation method and application thereof

A catalytic material and carbon fiber technology, applied in fuel cell half-cells and primary battery half-cells, electrical components, battery electrodes, etc., can solve problems such as poor conductivity of transition metal phosphide catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

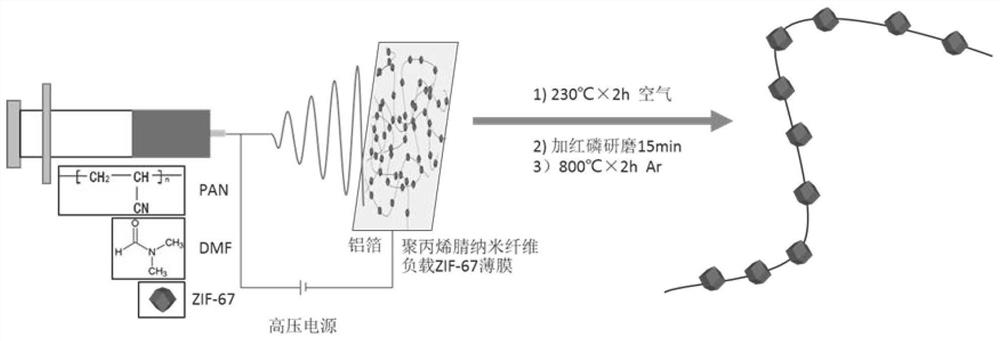

[0046] The invention provides a kind of preparation method of N, P double-doped carbon fiber supporting CoP composite catalytic material, comprising the following steps:

[0047] Mixing ZIF-67 organic solution and polyacrylonitrile organic solution to obtain spinning precursor;

[0048] Electrospinning the spinning precursor solution to obtain a flexible film;

[0049] Pre-oxidizing the flexible film to obtain a pre-oxidation product;

[0050] After the pre-oxidized product is mixed with red phosphorus, it is pyrolyzed in a protective atmosphere to obtain the N, P double-doped carbon fiber-loaded CoP composite catalytic material.

[0051] The invention mixes ZIF-67 organic solution and polyacrylonitrile organic solution to obtain spinning precursor solution.

[0052] In the present invention, ZIF-67 particles are preferably mixed with an organic solvent to obtain a ZIF-67 organic solution.

[0053] In the present invention, the particle size of the ZIF-67 particles is prefe...

Embodiment 1

[0093] figure 1 In Example 1, the preparation flow diagram of N, P double-doped carbon fiber loaded CoP composite catalytic material, ZIF-67 nanoparticles, polyacrylonitrile and DMF are mixed, and aluminum foil is used as the substrate for electrospinning to obtain polyacrylonitrile nanofibers Load the ZIF-67 film, and then perform pre-oxidation in air (230°C, 2h) to obtain the pre-oxidized product. After the pre-oxidized product is mixed with red phosphorus for 15 minutes, it is pyrolyzed in Ar (800°C, 2h), The N, P double-doped carbon fiber supported CoP composite catalytic material was obtained.

[0094]Step 1: Preparation of CoP@G / NP-PCNFs composite

[0095] Preparation of ZIF-67 nanoparticles: 2.5mmolCo(NO 3 ) 2 ·6H 2 Dissolve O in 50 mL of methanol, 20 mmol of 2-methylimidazole in 50 mL of methanol, then mix the two, stir at room temperature for 1 h, centrifuge to separate the precipitate, wash with methanol several times, and then heat to 60 ° C in a vacuum oven and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com