Wet desulphurization and dust removal equipment for industrial waste gas and use method thereof

A technology for wet desulfurization and dust removal equipment, applied in separation methods, chemical instruments and methods, combined devices, etc., can solve the problems of inability to meet emission standards, inability to perform a large amount of fog removal, and poor desulfurization effect, and increase the contact time. , the effect of increasing the contact area and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

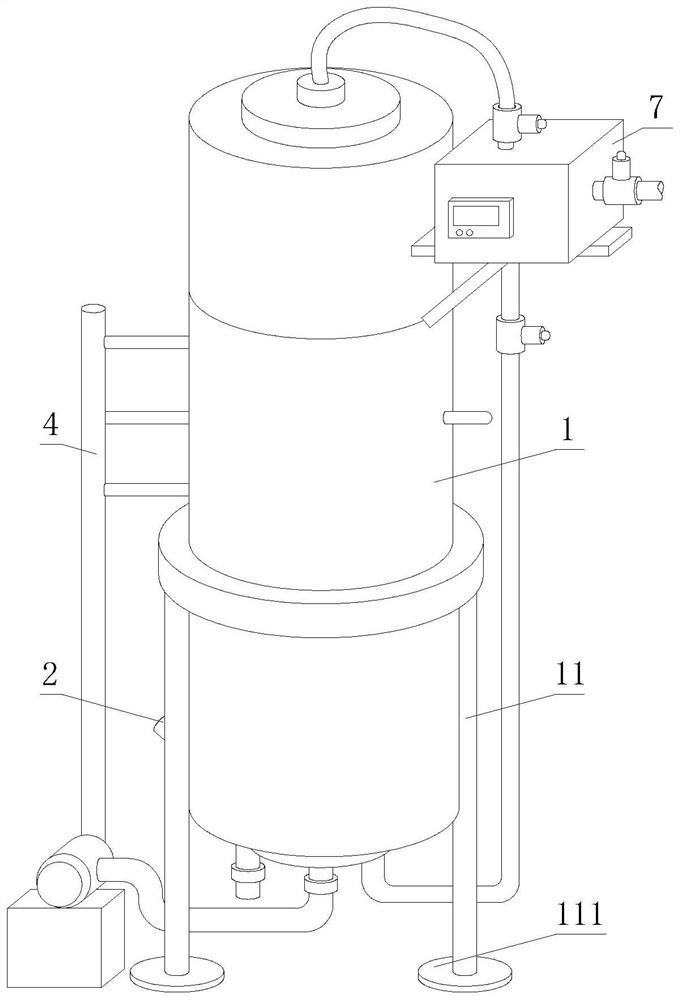

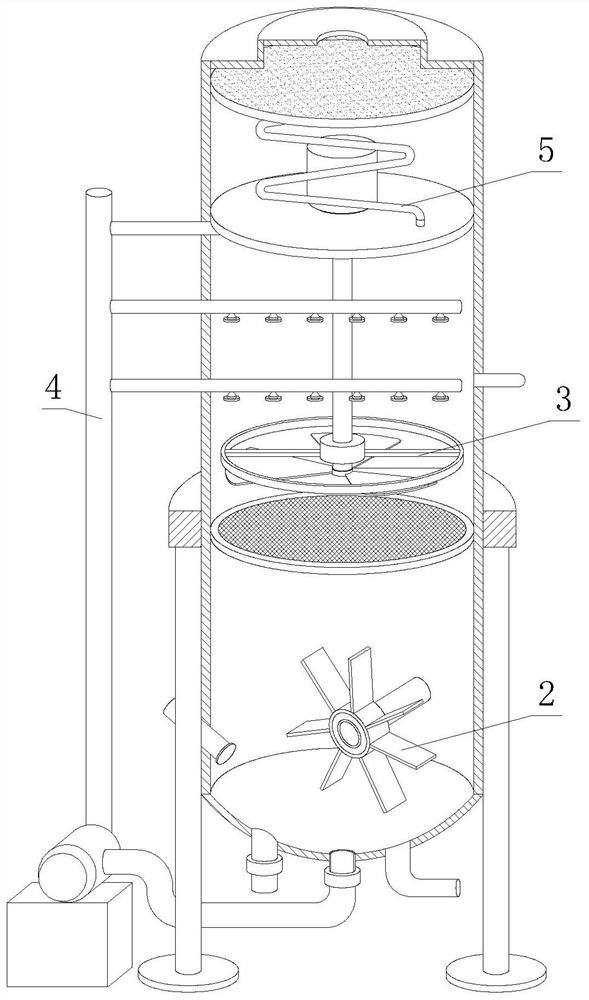

[0041] see Figure 1-Figure 2 , an industrial waste gas wet desulfurization and dust removal equipment and its use method, comprising an outer cylinder body 1, a bracket 11 is fixedly installed under the outer side of the outer cylinder body 1, a foot 111 is fixed under the bracket 11, and the interior of the outer cylinder body 1 is arranged The primary desulfurization device 2, the secondary desulfurization device 3 is installed in the outer cylinder 1 above the primary desulfurization device 2, the side end of the secondary desulfurization device 3 is provided with a spray device 4, and the top of the outer cylinder 1 is provided with a dehydration device 5, the dehydration device The 5 side end is connected with the detection device 6 .

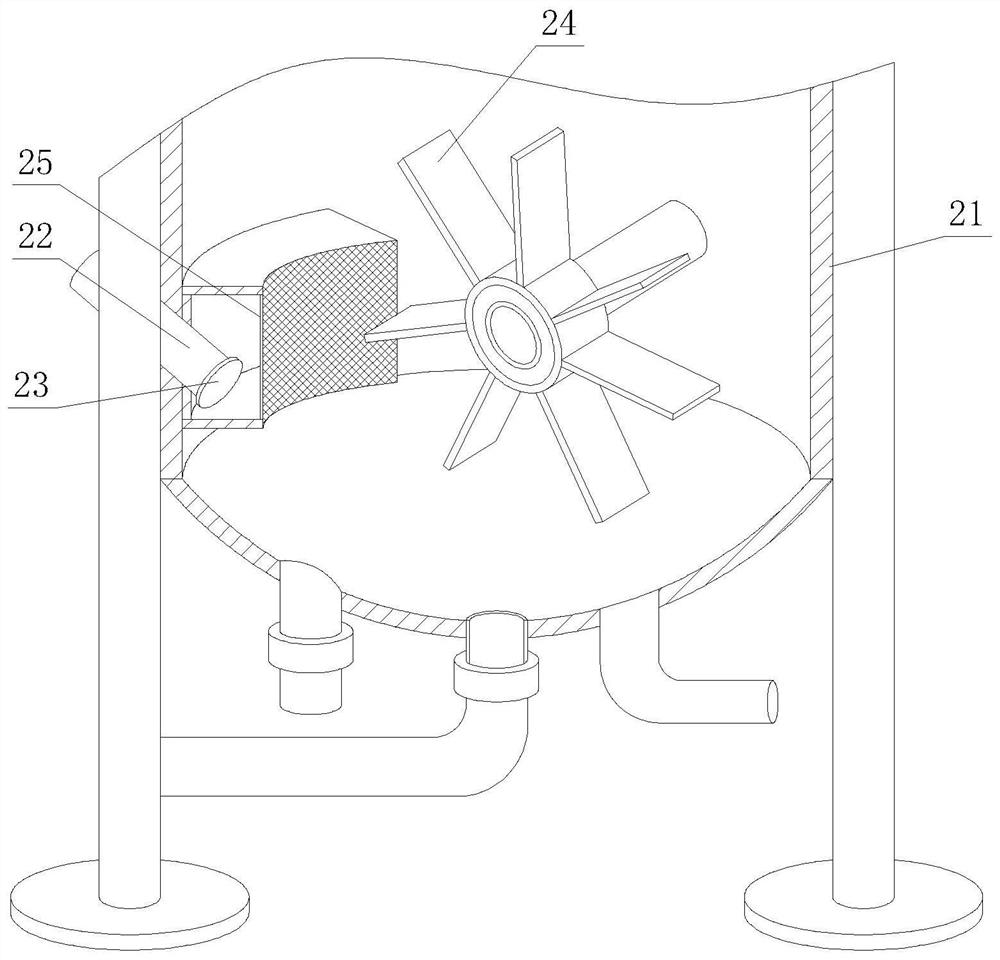

[0042] see image 3 , the preliminary desulfurization device 2 comprises a water tank 21, an air inlet pipe 22, an anti-backflow device 23, a stirring blade 24 and a dispersion net 25, and the stirring blade 24 is arranged in the water t...

Embodiment 2

[0053] see Figure 11 , an industrial waste gas wet desulfurization and dust removal equipment and its use method, comprising an outer cylinder body 1, a bracket 11 is fixedly installed under the outer side of the outer cylinder body 1, a foot 111 is fixed under the bracket 11, and the interior of the outer cylinder body 1 is arranged The primary desulfurization device 2, the secondary desulfurization device 3 is installed in the outer cylinder 1 above the primary desulfurization device 2, the side end of the secondary desulfurization device 3 is provided with a spray device 4, and the top of the outer cylinder 1 is provided with a dehydration device 5, the dehydration device 5. The side end is connected with the detection device 6. The preliminary desulfurization device 2 includes a water tank 21, an air intake pipe 22, an anti-backflow device 23, a stirring blade 24, and a dispersion net 25. The water tank 21 is provided with a stirring blade 24, and the side end of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com