Hierarchical porous composite metal oxide as well as preparation method and application thereof

A technology of composite metals and metal compounds, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of low catalytic efficiency of specific pore size metal catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing the multi-stage porous composite metal oxide described in the above technical solution, comprising the following steps:

[0032] The metal compound is mixed with the template agent, and the obtained mixture is ball-milled to obtain the first precursor. The metal compound includes any two of manganese metal compound, cerium metal compound, copper metal compound and iron metal compound. The template Agents include hard templating agents and soft templating agents;

[0033] The first precursor is calcined and the template agent is removed to obtain the multi-level porous composite metal oxide.

[0034] In the present invention, the metal compound and template agent are mixed, and the obtained mixture is ball-milled to obtain the first precursor, and the metal compound includes any two of manganese metal compound, cerium metal compound, copper metal compound and iron metal compound, The templating agent includes a hard ...

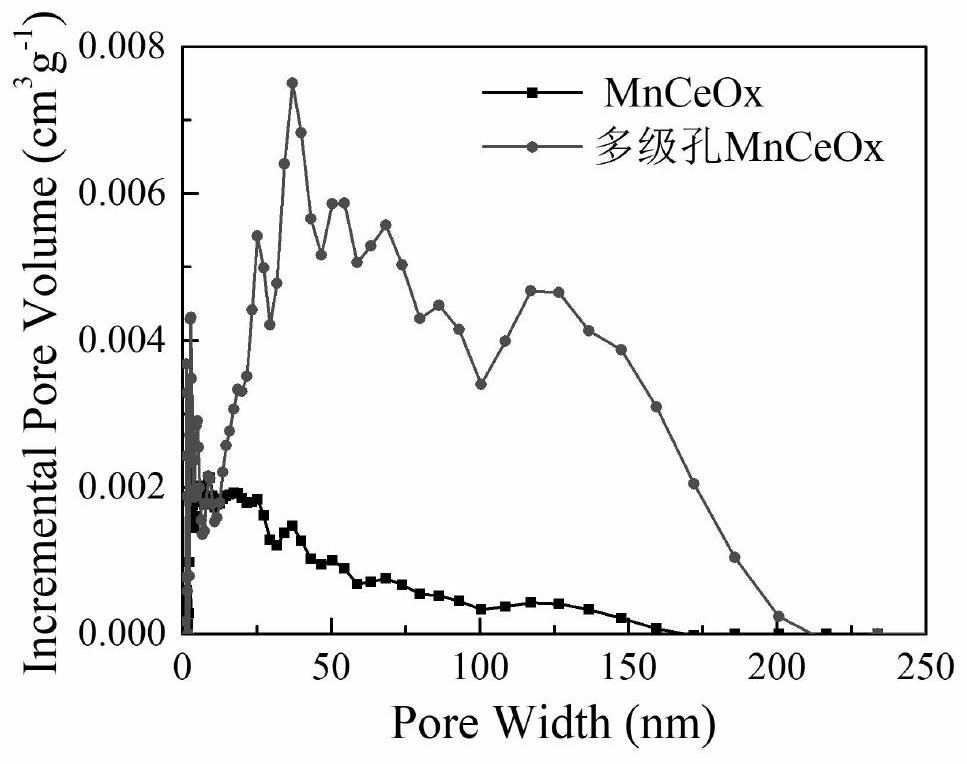

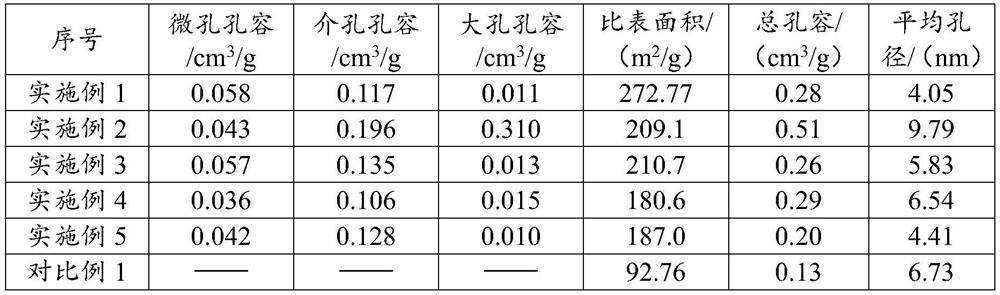

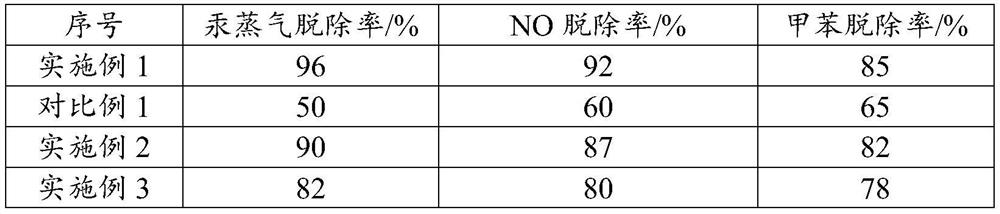

Embodiment 1

[0054] Weigh 2g of Ce(NO 3 ) 3 ·6H 2 O, 2g of Mn(NO 3 ) 2 , 2g SiO 2 , 0.8g of F127, add 2 quartz balls with a diameter of 0.7cm and 2 quartz balls with a diameter of 1.1cm, put them in a ball mill reactor, mill them at 30Hz for 60min, calcinate at 500°C for 3h, and cool to room temperature , mix the calcined product with 2.5mol / L NaOH solution, stir for 8h to remove SiO 2 Template, suction filtered, washed with deionized water until the solid product is neutral to the washed solution, and the solid product is placed in a drying oven for 24 hours to obtain a multi-level porous MnCeO x , the hierarchical channel MnCeO x The micropore volume is 0.058cm 3 / g; mesopore volume is 0.117cm 3 / g; the volume of the large pores is 0.011cm 3 / g; specific surface area 272.77m 2 / g, total pore volume 0.28cm 3 / g, the average pore diameter is 4.05nm.

Embodiment 2

[0056] Weigh 2g of Cu(NO 3 ) 2 ·6H 2 O, 2g of Mn(NO 3 ) 2 , 2g of PMMA, 0.8g of F127, add 2 quartz balls with a diameter of 0.7cm and 2 quartz balls with a diameter of 1.1cm, place them in a ball milling reactor, and after ball milling at 30Hz for 60min, calcinate at 500°C for 3h. After cooling to room temperature, the calcined product was mixed with 2.5mol / L NaOH solution and stirred for 8h to remove SiO 2 Template, suction filtered, washed with deionized water until the solid product is neutral to the washed solution, and the solid product is placed in a drying oven for 24 hours to obtain a multi-level porous CuMnO x , the hierarchical channels of CuMnO x The micropore volume is 0.043cm 3 / g; mesopore volume is 0.196cm 3 / g; the volume of the large pores is 0.31cm 3 / g; specific surface area 209.1m 2 / g, total pore volume 0.51cm 3 / g, the average pore diameter is 9.79nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com