A field simulation system and method of industrial robot based on augmented reality technology

An industrial robot and augmented reality technology, applied in manipulators, manufacturing tools, comprehensive factory control, etc., can solve problems such as interference and collision, damage to workpieces and tooling, and ensure the security of NC codes, so as to save time and money and make up for interference problems , Reduce the effect of debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

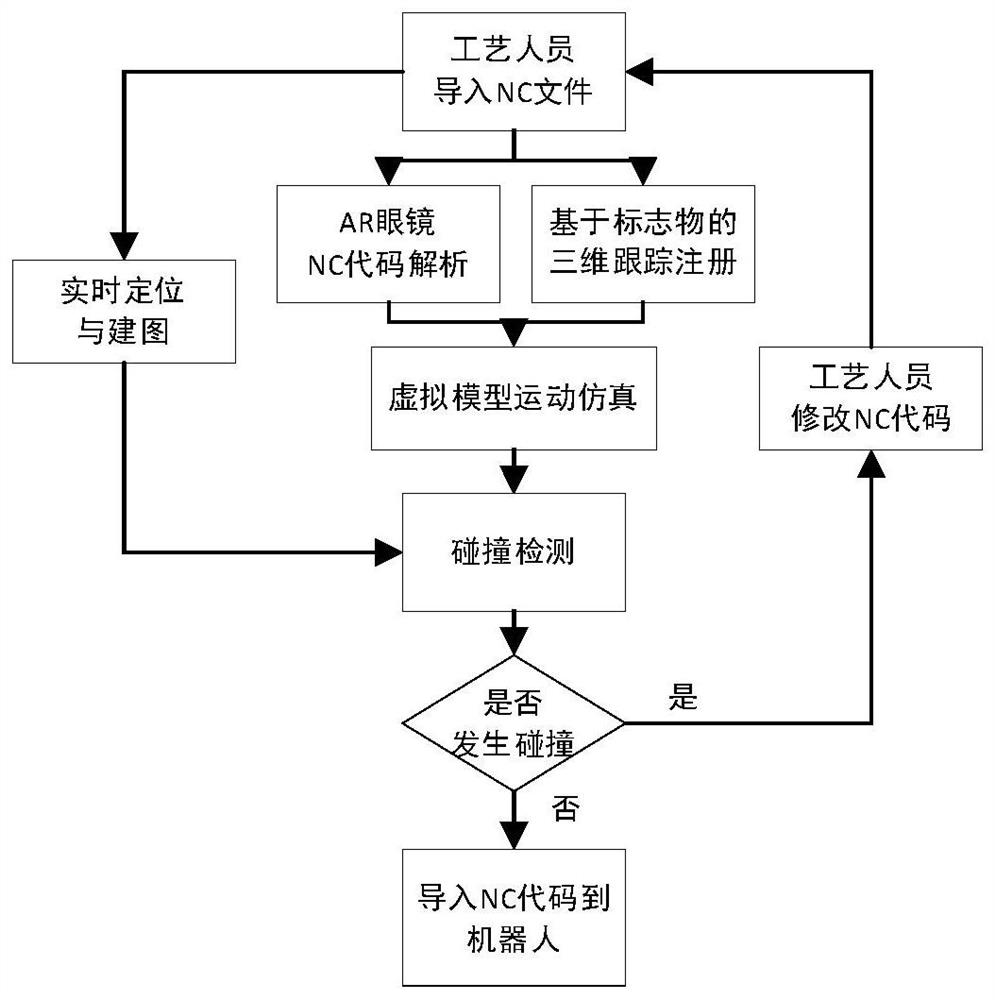

[0036] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

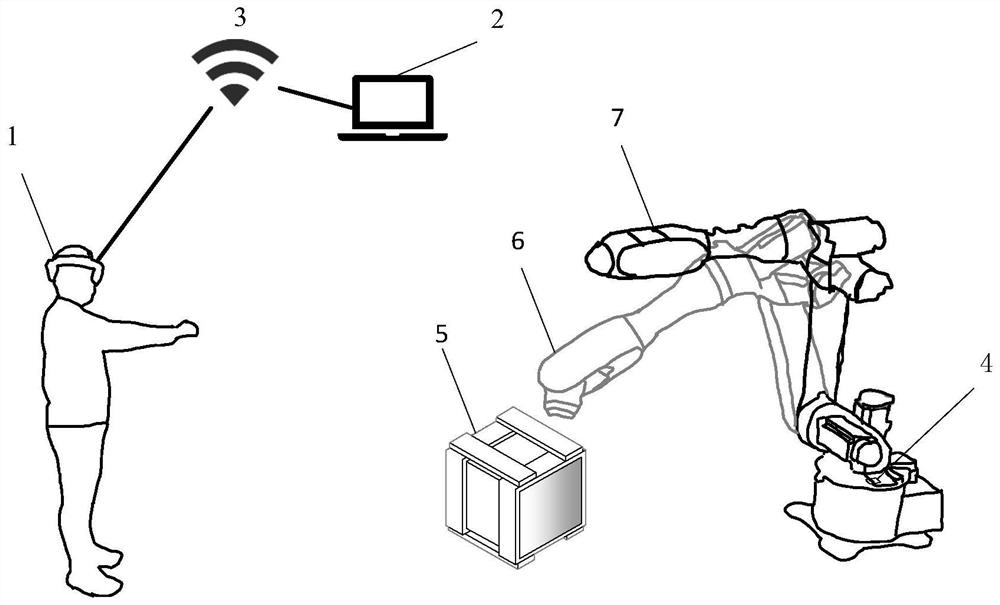

[0037] see figure 1 , an industrial robot on-site simulation system based on augmented reality technology of the present invention, including a physical industrial robot 7, a two-dimensional code 4, Hololens augmented reality glasses 1 and a controller 2;

[0038] The controller 2 controls the Hololens augmented reality glasses 1 to recognize the two-dimensional code 4, and realizes that the virtual robot 6 and the physical robot overlap in the Hololens augmented reality glasses 1;

[0039] The Hololens augmented reality glasses 1 drive the physical industrial robot 7 to move according to the command of the controller 2, so as to obtain the environment information of its moving area and perform collision detection.

[0040] figure 1 The middle obstacle 5 is an object that needs to avoid interference in the robot processing process.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com