Preparation method of polyphosphate synergistic nitrophosphate fertilizer

A technology of polyphosphate and nitrophosphate fertilizers, applied in magnesium fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of explosive phosphorus utilization rate, easy troughing, etc., achieve high nutrient absorption and utilization rate, improve effectiveness, promote The effect of improving quality and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

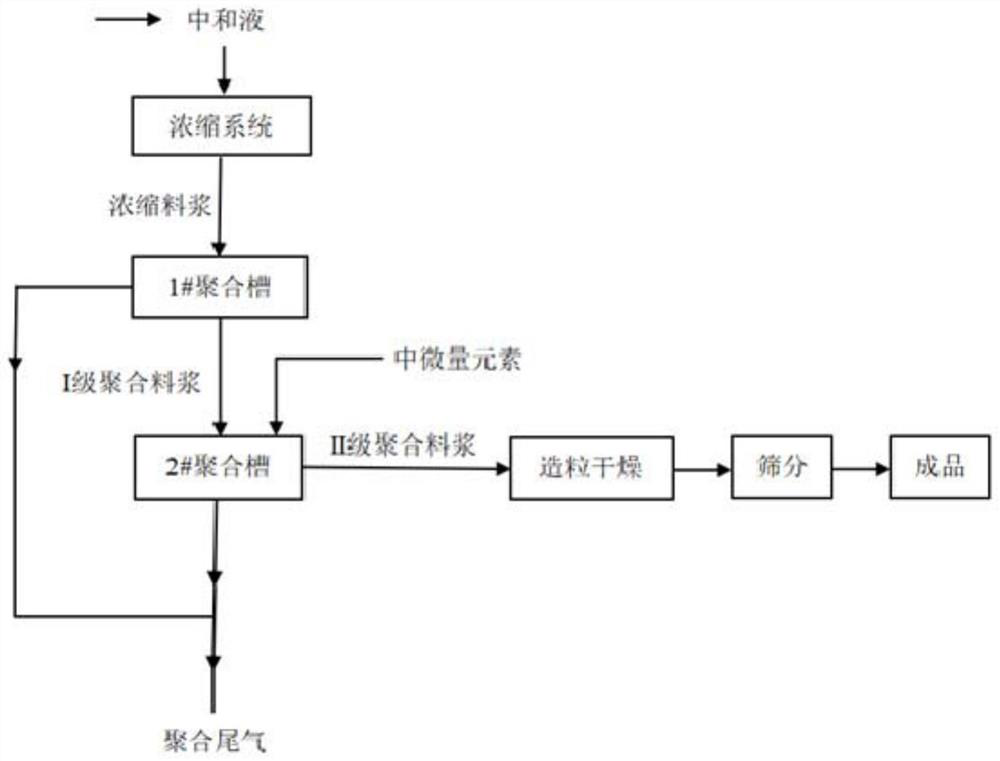

[0016] The embodiment of the present invention provides a kind of preparation method of polyphosphate synergistic nitrophosphate fertilizer, and described method comprises the following steps:

[0017] The present invention provides one, and it is characterized in that, the method specifically comprises the following steps:

[0018] S01: preparing neutralizing solution;

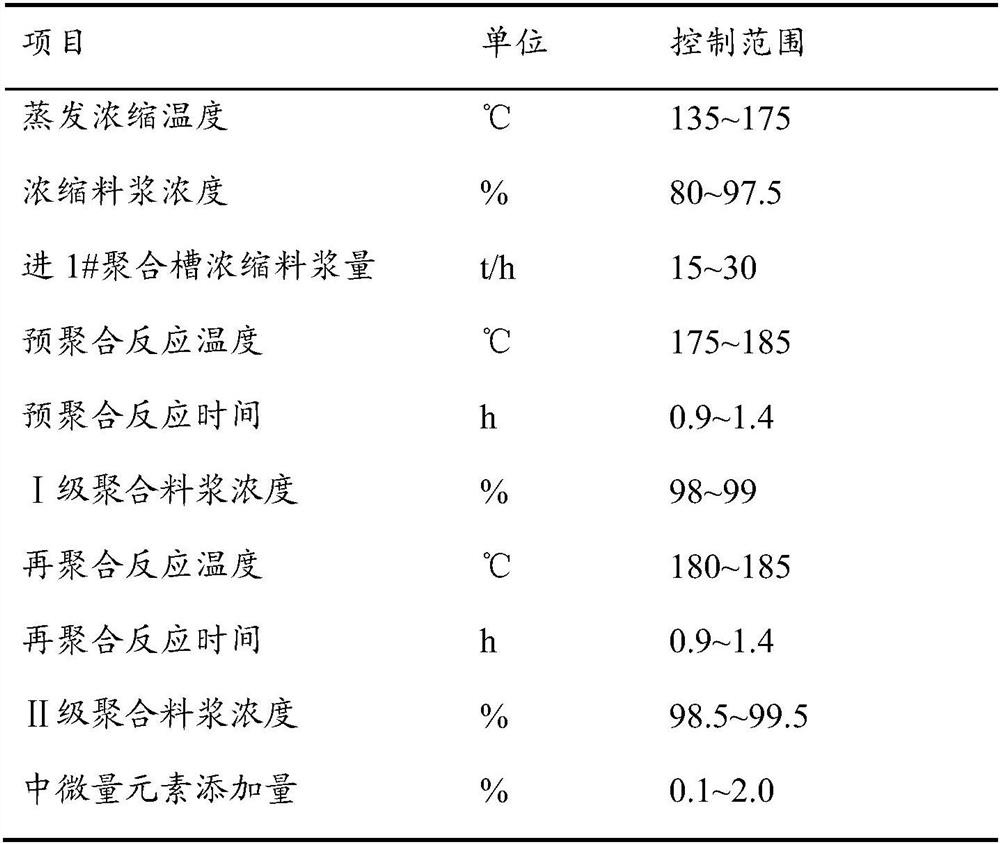

[0019] S02: pump the neutralization solution into the concentration system at 135-175°C for preheating, evaporation, and gas-liquid separation to obtain concentrated slurry;

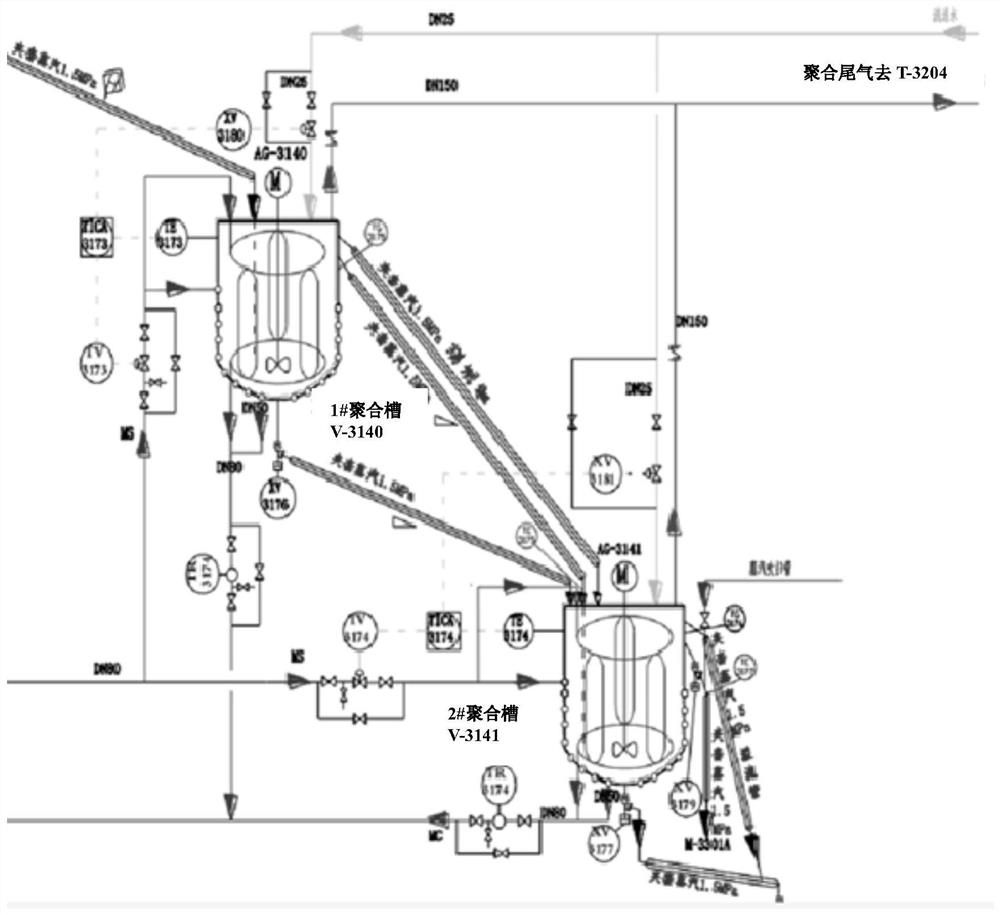

[0020] S03: Put the concentrated slurry into the 1# polymerization tank for pre-polymerization at 175-185°C to obtain grade I polymerization slurry;

[0021] S04: When the level of the first-grade polymerization slurry is full, overflow to the 2# polymerization tank, and add medium and trace elements to carry out re-polymerization under the condition of 180-185°C to obtain the second-grade polymerization slurry;

[0022] S05: Granulat...

Embodiment 1

[0046] The preparation method of polyphosphate synergistic nitrophosphate fertilizer specifically comprises the following steps:

[0047] 1) Preparation of neutralizing solution;

[0048] 2) Pump the neutralizing solution into the concentration system to perform preheating, evaporation, and gas-liquid separation at 175°C to obtain concentrated slurry with a mass concentration of 97.5%;

[0049] 3) Pre-polymerization: Put the concentrated slurry into the 1# polymerization tank, the feed rate is 25t / h, and heat the pre-polymerization under the condition of 180°C, the reaction time is 1.2h, and obtain the first-grade polymerization slurry with a mass concentration of 98.5 %;

[0050] 4) Re-polymerization: When the level of the first-stage polymerization slurry is full, overflow to 2# polymerization tank, add medium and trace elements, the mass fraction is 1.88% (magnesium oxide, zinc sulfate monohydrate, boric acid, the mass ratio of the three is 0.06:1.7 : 0.12), under the condi...

Embodiment 2

[0053] On the basis of Example 1, the temperature of step 2) evaporation and concentration was changed to 165° C. to prepare polyphosphate synergistic nitrophosphate fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com