Method for purifying semaglutide

A purification method and crude peptide technology, applied in the field of medicine and chemical industry, can solve the problems of affecting the purity and yield of the sample, poor solubility of the finished product, etc., and achieve the effect of good solubility of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

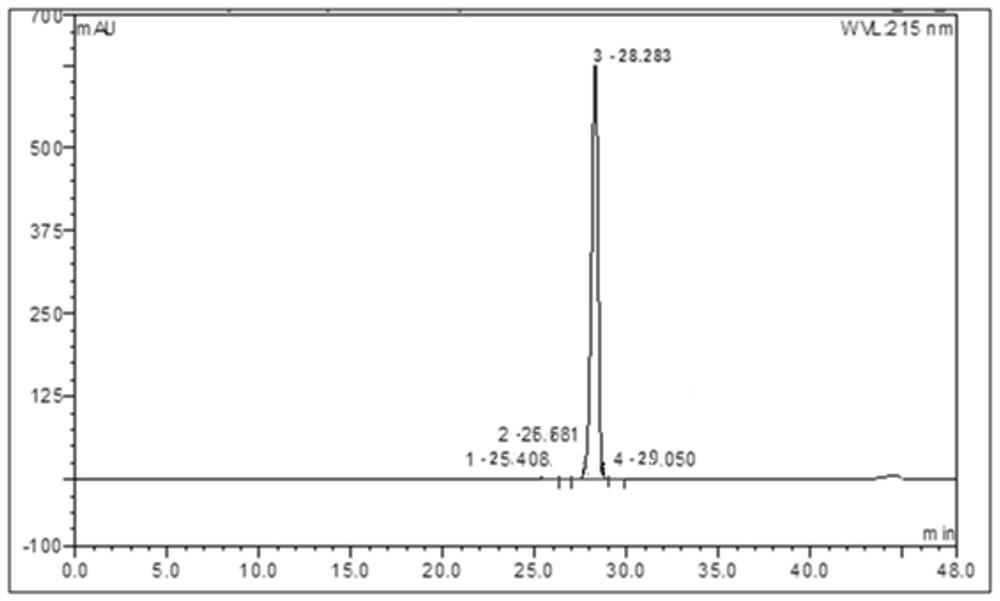

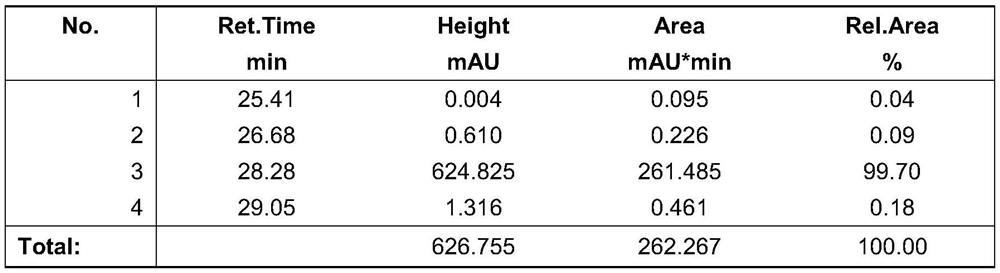

Image

Examples

Embodiment 1

[0029] A method for purifying semaglutide, comprising the steps of:

[0030] (1) Dissolution: Dissolve the crude semaglutide peptide at 5 mmol / L in an acetonitrile aqueous solution with a volume ratio (v / v) of 10%-20%, to obtain an aqueous solution of semaglutide, heat it in a water bath at 45°C for 2 hours, and then use 0.45 Filter with μm mixed filter membrane, spare;

[0031] The applicant found that due to the characteristics of the structure and composition of semaglutide itself, during the synthesis and cleavage process, the protective group of tryptophan is easily removed incompletely, and double peaks will appear on the analytical instrument, which has a negative impact on the purification yield. After repeated exploration by the applicant, when the crude peptide is completely dissolved, heating it in a water bath at a constant temperature of 40-45°C for 1.5-2 hours has the best effect, and can completely remove the protecting group. If the temperature is too low, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com