Preparation method of polyolefin solid-phase grafted maleic anhydride

A technology of maleic anhydride and solid-phase grafting, applied in the field of polyolefins, can solve problems such as increased production cost and high energy consumption, and achieve the effects of reducing material cost, solving environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

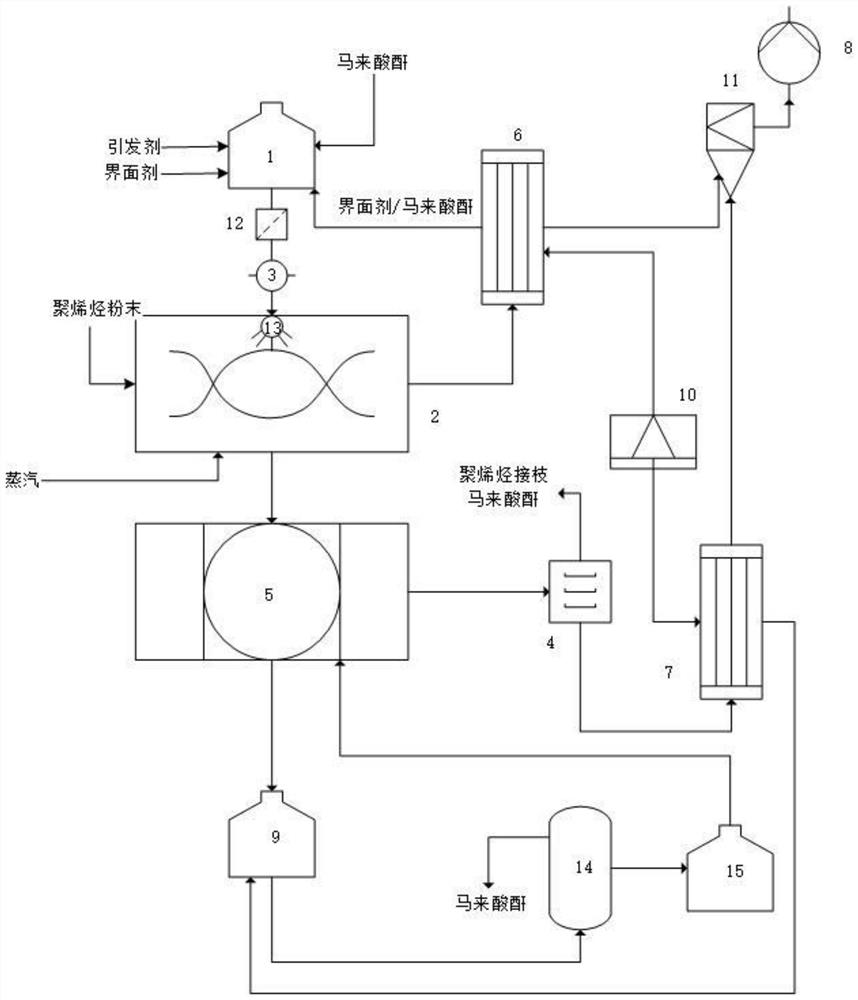

[0061] Such as figure 1 Shown, the production device of polyolefin solid-phase grafted maleic anhydride, it comprises: Liquid distribution tank 1, reactor 2, booster pump 3, drying tank 4, washing tank 5, first condenser 6, second condenser Device 7, vacuum pump 8, washing mixed liquid storage tank 9, flash tank 14 and washing liquid tank 15;

[0062] The liquid outlet and the return port are set on the liquid distribution tank 1, the liquid outlet is connected to the reactor 2, and the booster pump 3 is set on the connecting pipeline between the liquid outlet and the reactor 2; the liquid distribution tank 1 and the booster pump 3 are set filter 12;

[0063] A shower 13 and an agitator are arranged in the reactor 2, and a polyolefin inlet, a product outlet, a gas outlet, and a steam inlet are arranged on the reactor 2, and the gas outlet is connected to the inlet of the first condenser 6, The product outlet is connected with the washing kettle 5 .

[0064] The washing kett...

Embodiment 2

[0069] The production device provided in Example 1 is used, wherein the reactor is a vacuum cake reactor, the manufacturer is Changzhou Runyao Drying Equipment Co., Ltd., and the equipment model is ZKG-300.

[0070] The preparation steps of polypropylene solid-phase grafted maleic anhydride:

[0071] (1) 12L dimethylbenzene, 6.4kg tert-butyl peroxybenzoate and 10kg MAH are introduced into the liquid mixing tank, mechanically stirred for 20min at 45°C, MAH and tert-butyl peroxybenzoate are dissolved in xylene, form a clear solution;

[0072] (2) The viscosity-average molecular weight of 100kg is 2×10 5 The polypropylene powder is introduced into the vacuum rake reactor, the stirring is started, the stirring speed is set to 120rpm, and the reactor is purged with nitrogen to discharge the air; the rake reactor is protected with nitrogen;

[0073](3) After the transparent solution formed in step (1) is filtered through a filter, use a booster pump to spray into the rake reactor,...

Embodiment 3

[0081] The production device provided in Example 1 is used, wherein the reactor is a vacuum cake reactor, the manufacturer is Changzhou Runyao Drying Equipment Co., Ltd., and the equipment model is ZKG-300.

[0082] The preparation steps of polypropylene solid-phase grafted maleic anhydride:

[0083] (1) Import 10L of toluene, 5.0kg of benzoyl peroxide and 10kg of MAH into the liquid mixing tank, and mechanically stir at 50°C for 30 minutes to dissolve MAH and benzoyl peroxide in toluene to form a transparent solution;

[0084] (2) The 100kg viscosity average molecular weight is 4×10 4 The polypropylene powder is introduced into the vertical ribbon reactor, the stirring is started, the stirring speed is set to 110rpm, and the reactor is purged with nitrogen to discharge the air therein; the vertical ribbon reactor is protected with nitrogen;

[0085] (3) After the transparent solution formed in the step (1) is filtered through a filter, it is added to the vertical ribbon reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com