Microbial flocculant as well as preparation method and application thereof

A microbial flocculant and microbial technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high preparation cost, large dosage, and high cost of microbial flocculants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Screening and identification of flocculation microbial strains

[0020] 1. Experimental materials

[0021] The test material is the activated sludge of the No. 2 Sewage Plant in Ma'anshan City, Anhui Province;

[0022] 2. Medium

[0023] LB liquid medium: tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L;

[0024] LB solid medium: tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L, agar 20g / L.

[0025] Screening of flocculating microbial strains: Collect activated sludge samples from the sludge of the No. 2 Sewage Plant in Ma'anshan City, Anhui Province, weigh 10g of sludge samples into a beaker filled with 100mL of sterile distilled water, and stir them evenly with a magnetic stirrer; then, The samples were sequentially divided into 10 -1 , 10 -2 , 10 -3 , 10 -4 , 10 -5 , 10 -6 Six gradient dilutions; take 0.2mL of the diluted sample and evenly coat LB medium, place the plate upside down in a constant temperature incubator at 30°C for 48 hours; pick 12 str...

Embodiment 2

[0035] Example 2: Optimization of culture conditions for flocculant-producing microbial strain XN-1

[0036] (1) Temperature: Use an inoculation loop to pick up the XN-1 strain stored on the LB slope into 5 mL of LB liquid medium, shake and culture at 30°C and 180 rpm for 24 hours, and transfer 50 μL of the bacterial liquid to fresh In 5mL LB medium, cultured at different temperature conditions of 25°C, 30°C, 35°C, and 37°C for 48 hours, respectively, and measured the flocculation rate of the strains; The flocculation rate is up to 92%.

[0037] (2) pH: Use an inoculation loop to pick up the XN-1 strain stored on the LB slope into 5 mL of LB liquid medium, shake and culture it at 180 rpm at 35°C for 24 hours, and transfer 50 μL of the bacterial liquid to fresh The pH is respectively in 5mL LB culture medium of 4,5,6,7,8,9, measure the growth situation of OD600 comparison bacterial strain by ultraviolet spectrophotometer, the result shows that in the pH range of 5-8, bacterial...

Embodiment 3

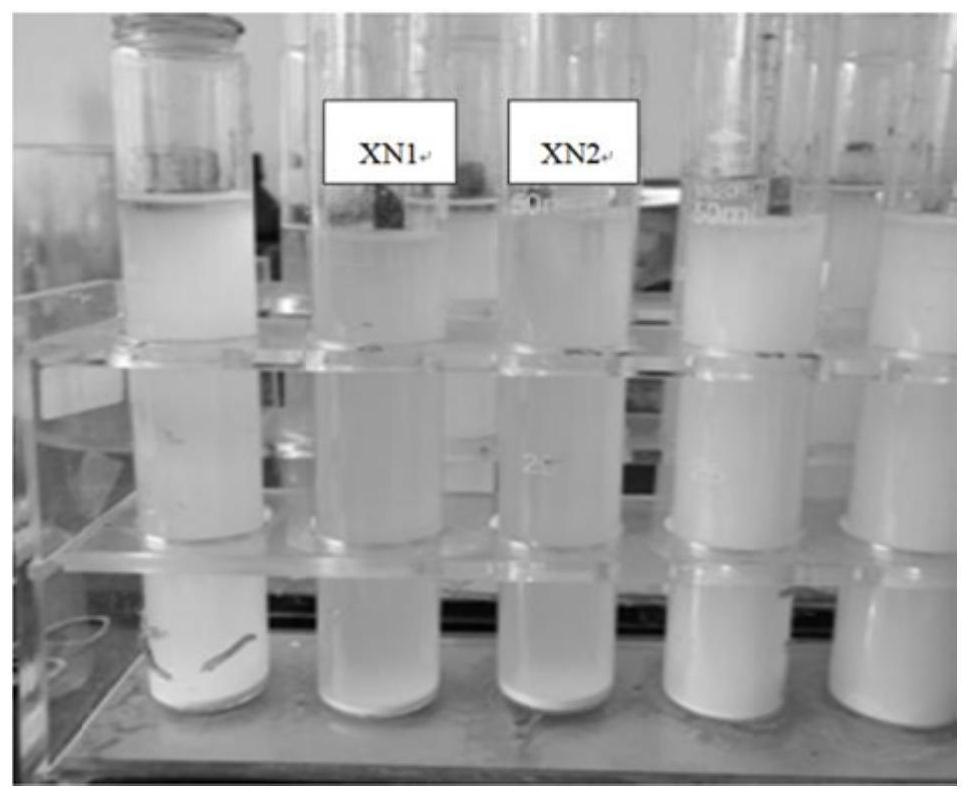

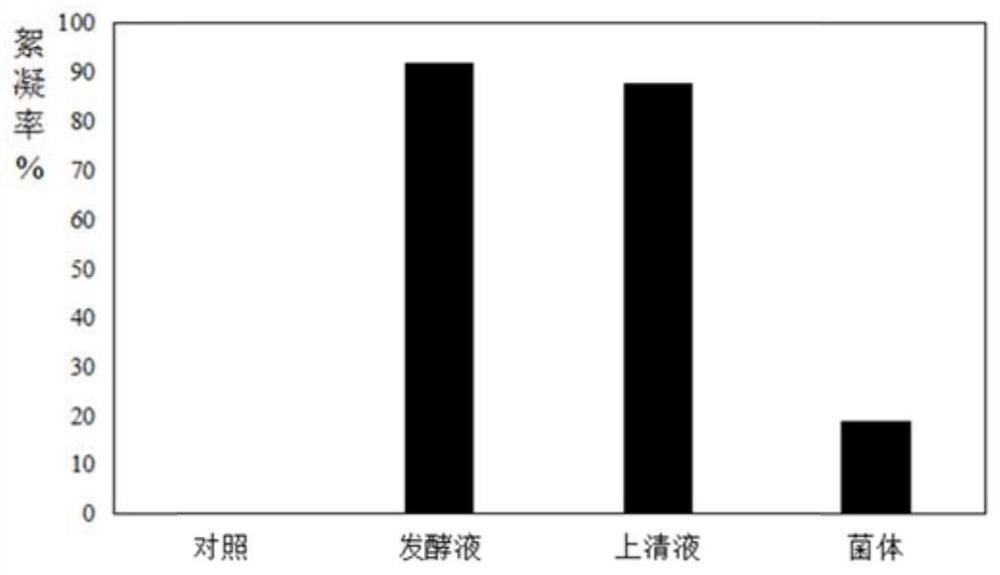

[0039] Example 3: Activity distribution and extraction of microbial flocculants

[0040] Inoculate 0.5mL of XN-1 bacteria solution into two Erlenmeyer flasks filled with 50mL of LB liquid medium, and culture at 30°C and 180rpm for 48h. Collect one of the bottles of fermentation broth, centrifuge at 12000r / min for 10min, separate the supernatant from the cells, wash the cells twice with distilled water, suspend the cells in distilled water equal to the volume of the supernatant, and place Shake on a shaker for several minutes to mix evenly to obtain a bacterial cell suspension. Taking LB medium as a blank control, add equal volumes of fermentation broth, supernatant, bacterial suspension and culture medium into the kaolin flocculation system to measure its flocculation effect. The results are shown in figure 2 . Both the fermentation broth and the supernatant showed high flocculation activity, and the flocculation activity of bacterial cells was low, so most of the flocculants...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com