Preparation method of carbon nanotube fiber loaded nano iron oxide composite material

A technology of carbon nanotube fiber and nano-iron oxide, which is applied in the direction of iron oxide, carbon fiber, carbon compound, etc., can solve problems such as low efficiency, high equipment requirements, and complex operation of the synthesis process, and achieve good application prospects and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) ferrocene is dissolved in sherwood oil, and preparation concentration is the ferrocene solution of 1wt%;

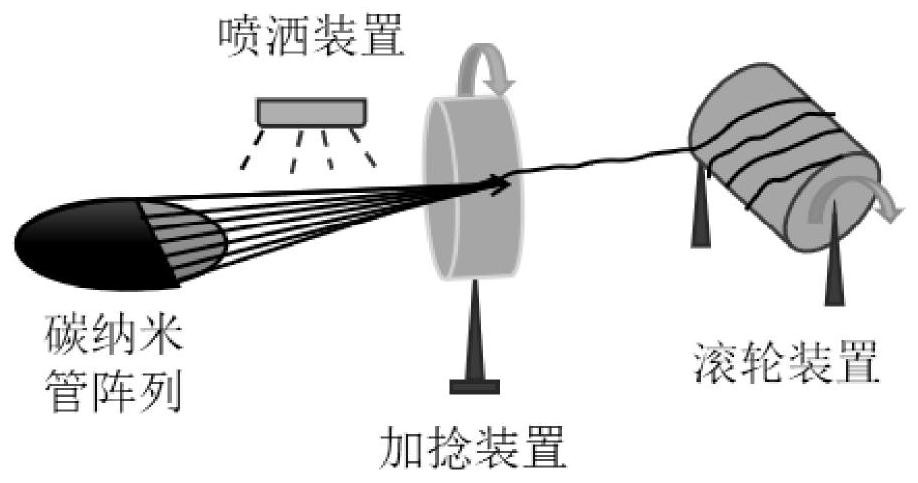

[0035] (2) if figure 1 As shown, the carbon nanotube array with a diameter of 80 mm is first drawn by the array spinning method to form a carbon nanotube film, and then the carbon nanotube film is twisted to form a carbon nanotube fiber with a diameter of 100 μm. In the process, spray the ferrocene solution obtained in step (1) to the surface of the formed carbon nanotube film;

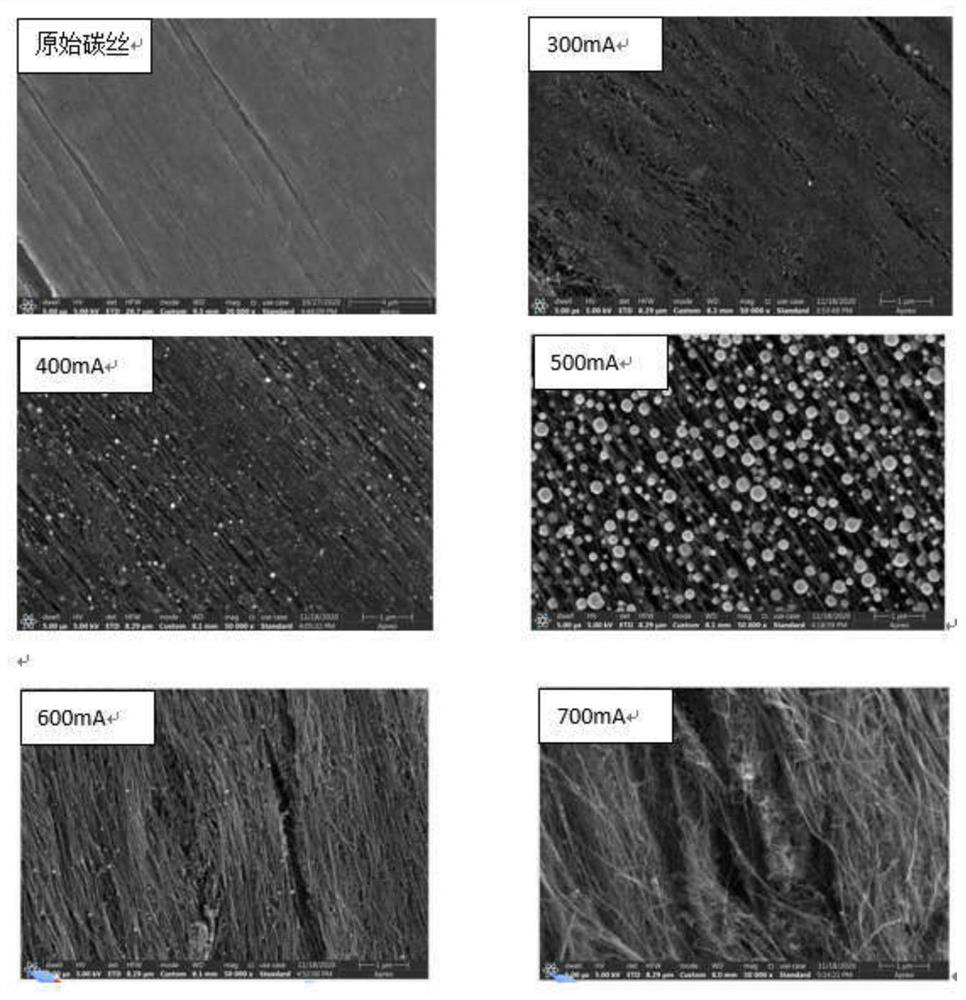

[0036] (3) Under a high-purity argon atmosphere, the carbon nanotube fibers prepared in step (2) were subjected to Joule heat treatment for 30 s, and the current intensity of the DC power supply for the Joule heat treatment was 500 mA.

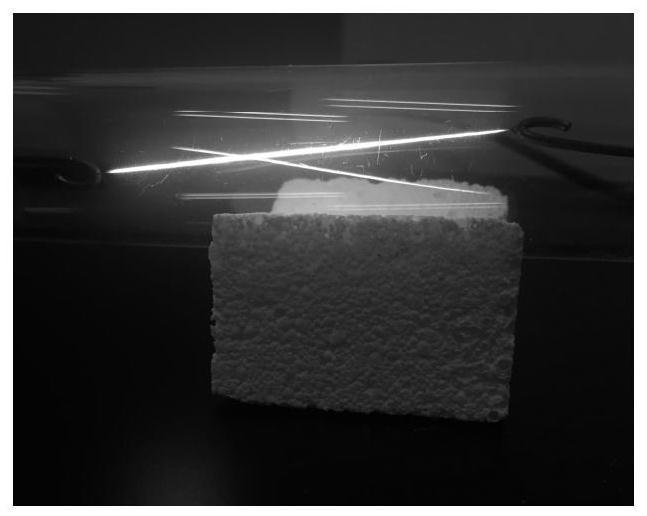

[0037] Such as figure 2 As shown, the carbon nanotube fiber-loaded nano-iron oxide composite material prepared in this example can emit brighter light, and the degree of brightness varies with the current. Depend on image 3 It is known that the s...

Embodiment 2

[0039] (1) ferrocene is dissolved in sherwood oil, and preparation concentration is the ferrocene solution of 0.5wt%;

[0040] (2) if figure 1 As shown, the carbon nanotube array with a diameter of 60 mm is first stretched by the array spinning method to form a carbon nanotube film, and then the carbon nanotube film is twisted to form a carbon nanotube fiber with a diameter of 110 μm. In the process, spray the ferrocene solution obtained in step (1) to the surface of the formed carbon nanotube film;

[0041] (3) Under a high-purity argon atmosphere, the carbon nanotube fibers prepared in step (2) were subjected to Joule heat treatment for 30 s, and the current intensity of the DC power supply for the Joule heat treatment was 300 mA.

[0042] Such as figure 2 As shown, the surface of the carbon nanotube fiber-loaded nano-iron oxide composite material prepared in this example has basically no composite of larger iron oxide, but there are extremely small particles on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com