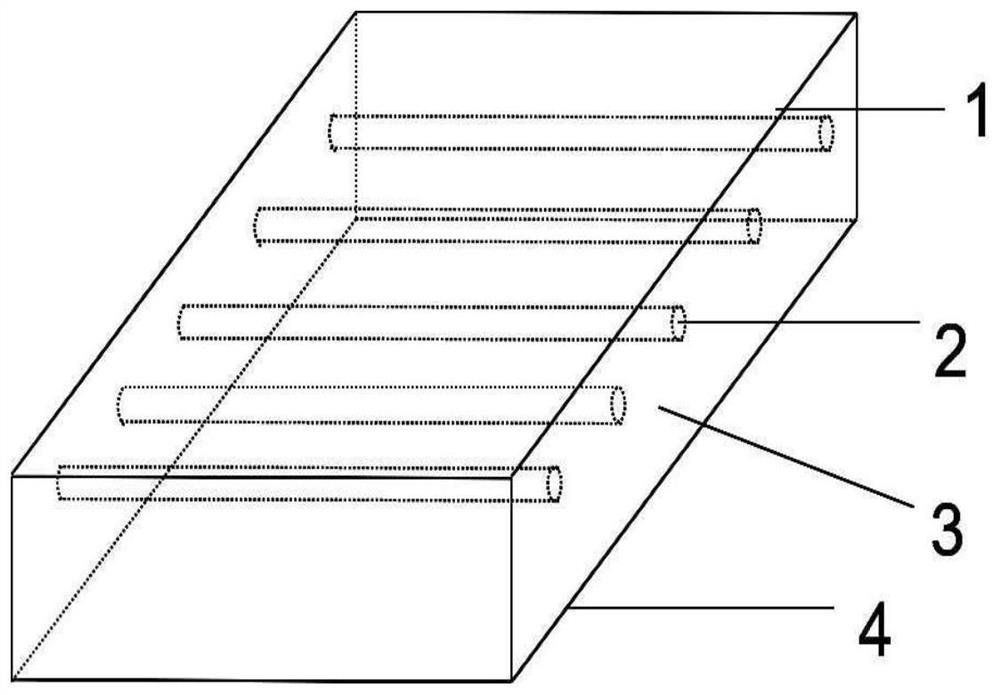

Self-stress pavement and phase change material mixed pavement ice melting system and construction method

A phase change material and self-stressing technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of low melting efficiency, short life, high power required for melting ice and snow, etc., to improve melting efficiency, inhibit road icing, The effect of reducing the difficulty of melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

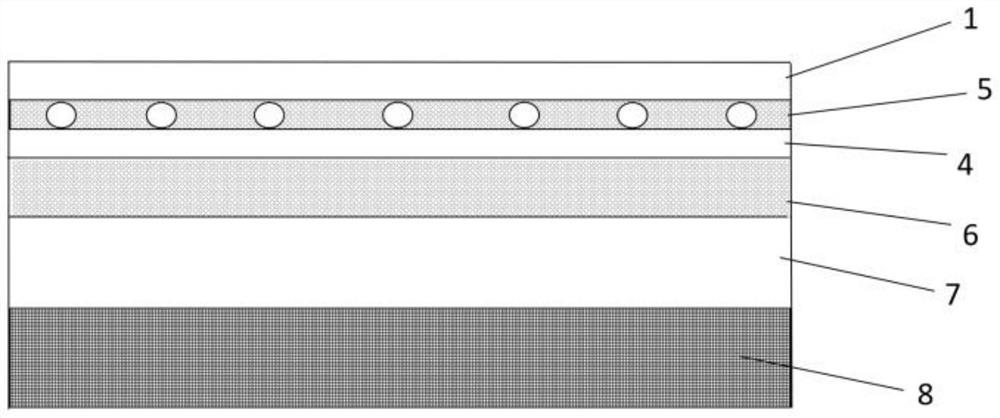

[0046] The specific steps for implementation are as follows:

[0047] 1) According to the road asphalt pavement construction technical specifications and construction process requirements, lay the road cushion 8 and the road base 7 sequentially on the road soil base, after the road base 7 is laid, lay an asphalt concrete layer on the upper surface of the road base 7; After the asphalt concrete layer 6 is laid, heat insulating material is laid on its upper surface. The material has sufficient bearing capacity, small size change, thermal conductivity not greater than 0.020W / m·k, surface density not less than 25kg / m3, and compression resistance. The strength is not less than 250kPa, and the linear shrinkage rate is not more than 0.003. Based on this, vitrified microbead thermal insulation mortar is selected, and the thickness is about 15 mm to form the thermal insulation layer 4 .

[0048] 2) Lay high-quality carbon structural steel pipes horizontally on the heat insulation laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com