Zero-emission gravel production wastewater treatment system and process

A technology for the production of waste water and treatment systems, which is applied in ceramic waste water treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of not being able to keep up with the production progress, the sewage tank cannot accommodate muddy water, and stop production, etc., to achieve Save water treatment costs, prevent soil erosion, and reduce water intake costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

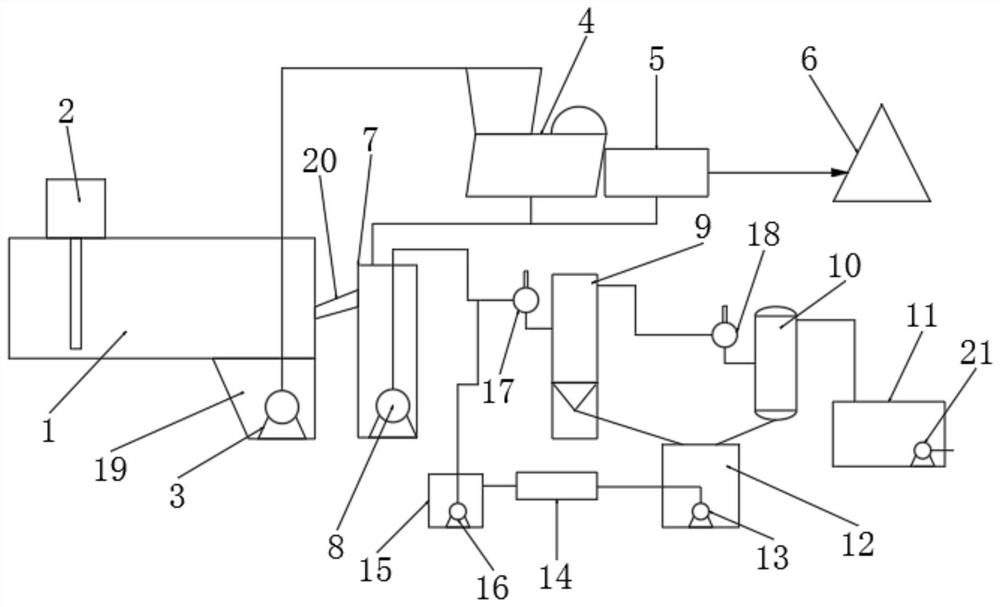

[0025] Such as figure 1 Shown is the structural representation of the present invention:

[0026] The present invention provides a waste water treatment system for zero-discharge sandstone production, including a sedimentation tank 1, a sand washing machine 4, a sand bin 6, a sewage well 7, a vertical flow clarifier 9, a high-efficiency and rapid separator 10, a clear water tank 11, a sewage Mud tank 12, sludge drying equipment 14, the sedimentation tank 1 is provided with a sand scraper 2, and one end of the bottom of the sedimentation tank 1 is provided with a sand pump 3, and the outlet of the sand pump 3 is connected to a sand washing machine 4 for sand washing The outlet of the machine 4 is provided with a dewatering screen 5, and the dewatering screen 5 and the sand bin 6 are connected by a conveyor belt; the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com