Nano-composite cross-linking agent for fracturing fluid and preparation method of nano-composite cross-linking agent

A nano-composite and cross-linking agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex liquid preparation and complex components, and achieve simple liquid preparation, simple preparation methods, and easy popularization and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, a nanocomposite cross-linking agent for fracturing fluid was prepared, and its formula in terms of moles was: 5 mol of citric acid, 2.5 mol of diethylenetriamine, 5 mol of zirconium oxychloride, and 2000 mL of deionized water.

[0025] Its specific preparation method is:

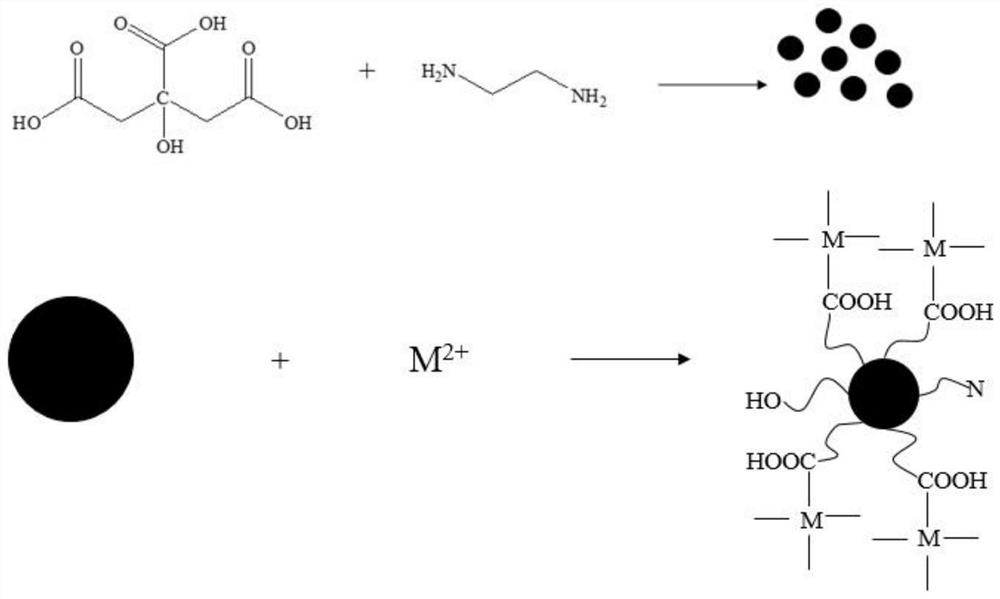

[0026] Step 1: Weigh citric acid and diethylenetriamine according to the above formula, add them into deionized water, stir and mix to obtain a mixed solution; heat the mixed solution to 180°C, react for 8 hours, and the reaction is completed to obtain a liquid system of nano-carbon quantum dots ;

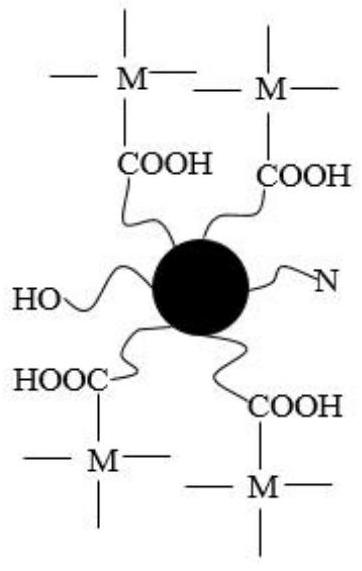

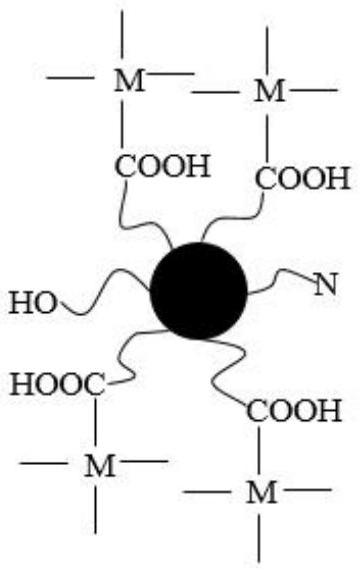

[0027] Step 2: Add zirconium oxychloride into the above liquid system according to the above formula, stir to dissolve the zirconium oxychloride completely, and react for 1.5 hours to obtain nano-crosslinking agent A.

Embodiment 2

[0029] In this example, a nanocomposite cross-linking agent for fracturing fluid was prepared, and its formula in terms of moles was: 5 mol of citric acid, 5 mol of ethylenediamine, 25 mol of zirconium oxychloride, and 2000 mL of deionized water.

[0030] Its specific preparation method is:

[0031] Step 1: Weigh citric acid and ethylenediamine according to the above formula, add them into deionized water, stir and mix to obtain a mixed solution; heat the mixed solution to 250° C., react for 4 hours, and the reaction is completed to obtain a liquid system of nano-carbon quantum dots;

[0032] Step 2: Add zirconium oxychloride into the above liquid system according to the above formula, stir to dissolve the zirconium oxychloride completely, and react for 3 hours to obtain nano-crosslinking agent B.

Embodiment 3

[0034] In this example, a nanocomposite cross-linking agent for fracturing fluid was prepared, and its formula in terms of moles was: 5 mol of citric acid, 4 mol of diethylenetriamine, 15 mol of zirconium oxychloride, and 2000 mL of deionized water.

[0035] Its specific preparation method is:

[0036] Step 1: Weigh citric acid and diethylenetriamine according to the above formula, add them into deionized water, stir and mix to obtain a mixed solution; heat the mixed solution to 200°C, react for 5 hours, and the reaction is completed to obtain a liquid system of nano-carbon quantum dots ;

[0037] Step 2: Add zirconium oxychloride into the above liquid system according to the above formula, stir to dissolve the zirconium oxychloride completely, and react for 2 hours to obtain nano-crosslinking agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com