Waste gas treatment device used for catalytic combustion

An exhaust gas treatment device and catalytic combustion technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of uneven mixing of exhaust gas and catalyst, affecting the efficiency of catalytic work, etc., to reduce mixing time, improve practicability, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

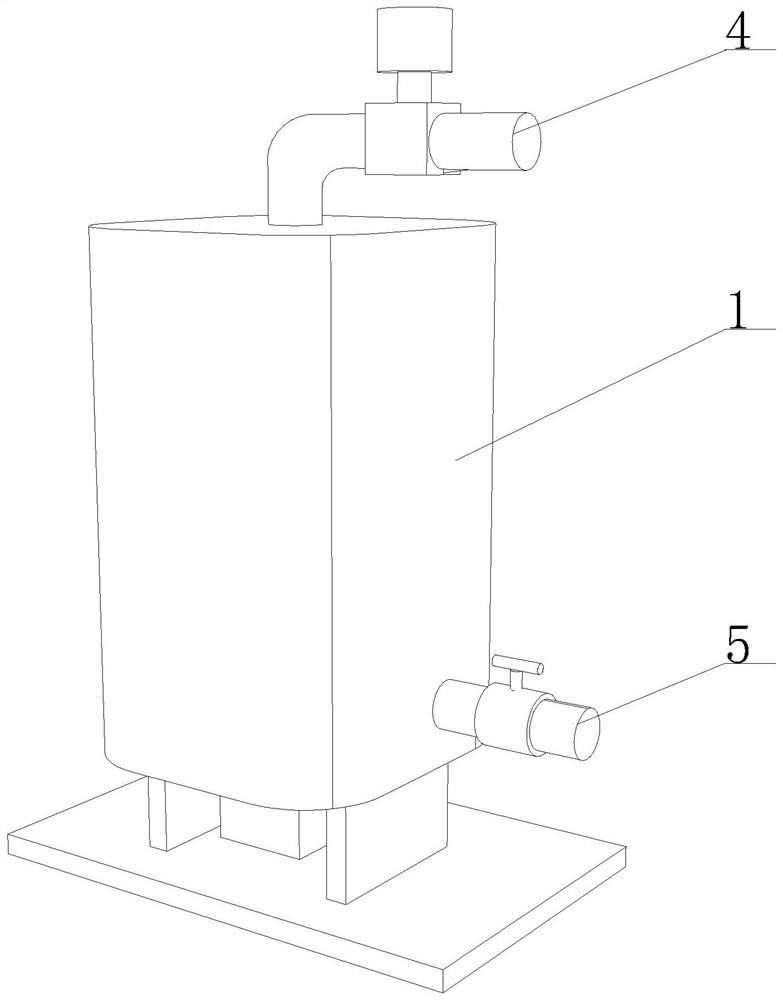

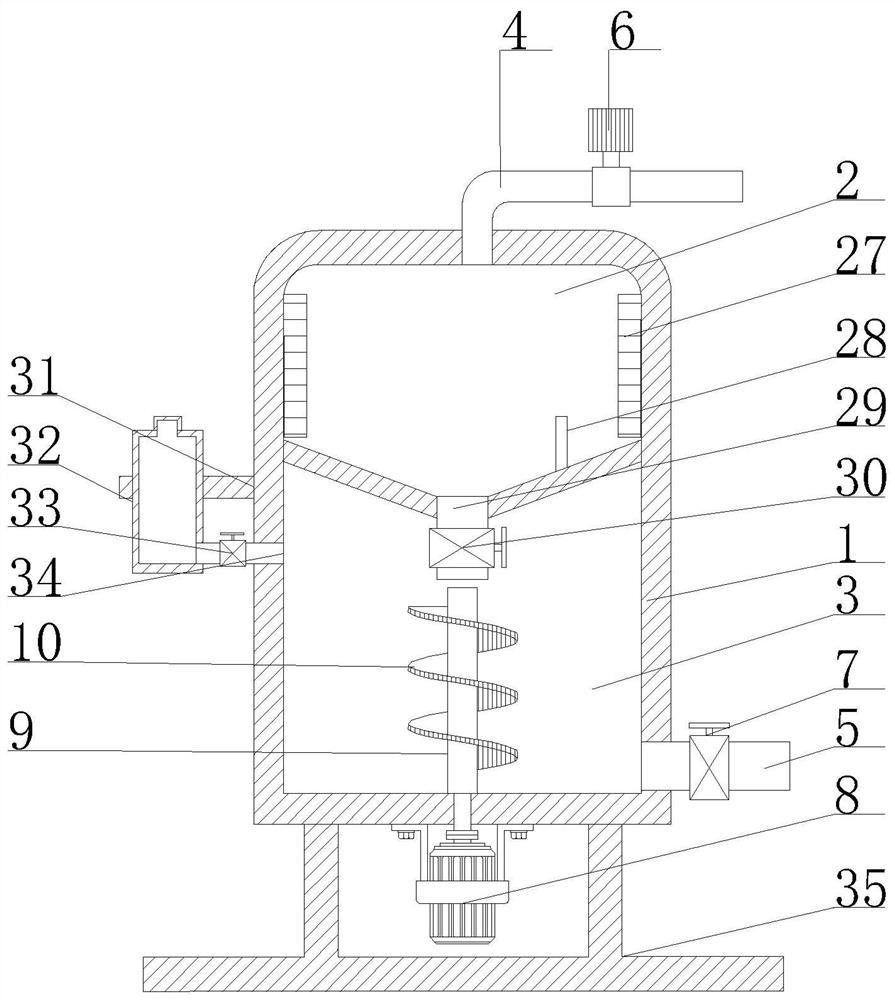

[0034] Such as figure 1 - figure 2 As shown, the present invention provides an exhaust gas treatment device for catalytic combustion, including a treatment mechanism 1, a heating chamber 2, a catalytic chamber 3, an air inlet pipe 4, an air outlet pipe 5, a negative pressure pump 6, and a first valve 7 , a drive motor 8, a rotating roller 9 and a spiral blade 10, a heating chamber 2 and a catalytic chamber 3 are provided inside the processing mechanism 1, the heating chamber 2 is located above the catalytic chamber 3, and the top of the processing mechanism 1 is provided with an inlet Trachea 4, negative pressure pump 6 is arranged on the surface of air inlet pipe 4, outlet pipe 5 is arranged on the bottom right side of processing mechanism 1, first valve 7 is arranged on the surface of outlet pipe 5, and drive motor 8 is arranged on the bottom of processing mechanism 1 , the output end of the driving motor 8 is provided with a rotating roller 9 , the rotating roller 9 penet...

Embodiment 2

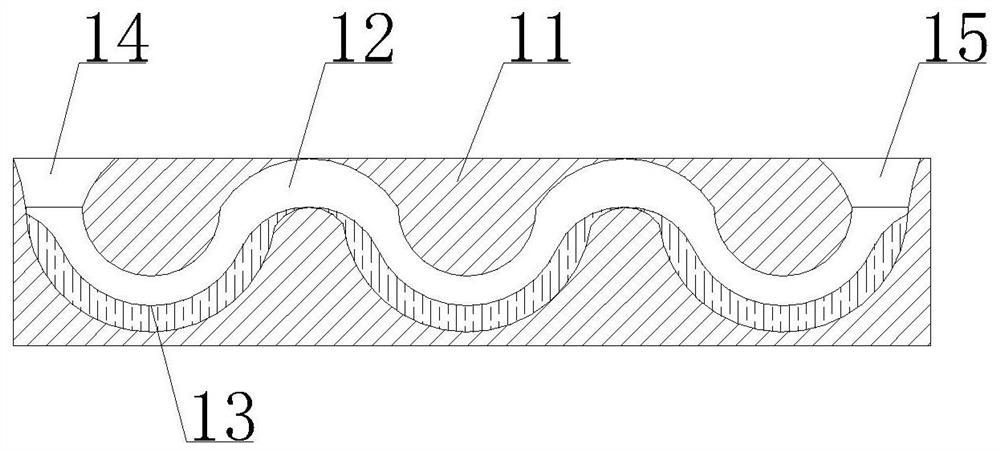

[0037] Such as Figure 3-7 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: helical blade 10 comprises blade body 11 and flow groove 12, and the top surface of blade body 11 is provided with feed inlet 14, and the bottom surface of blade body 11 There is a discharge port 15, the feed port 14 and the discharge port 15 are connected through the set flow tank 12, the bottom of the inner wall of the flow tank 12 is provided with a filter mechanism 13, and the surface of the filter mechanism 13 is provided with a filter tank 16, the filter tank The bottom of the inner wall of 16 is provided with a viscous filter layer 17 to the left, and the bottom of the filter tank 16 is provided with an arc-shaped groove 18 to the left. The viscous filter layer 17 includes a viscous adsorption layer 22 and an adhesive bristle 23. The inner wall of the groove 16 is fixedly connected, the top of the viscous adsorption layer 22 is uniformly provided wi...

Embodiment 3

[0039] Such as Figure 1-2 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the inner wall side of the heating chamber 2 is provided with a heater 27, and the inner wall bottom of the heating chamber 2 is provided with a temperature sensor device 28, the bottom of the heating chamber 2 communicates with the catalytic chamber 3 through the flow pipe 29 provided, the surface of the flow pipe 29 is provided with a solenoid valve 30, the temperature sensing device 28 is connected with the signal of the solenoid valve 30, and the left side of the processing mechanism 1 The side is movably connected with a catalyst storage bottle 32 through a fixed bracket 31 provided, and the bottom of the catalyst storage bottle 32 is provided with a feeding pipe 33, and the feeding pipe 33 runs through the processing mechanism 1 and extends inside the catalytic chamber 3, and the feeding pipe 33 A second valve 34 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com