Antibiotic feed substitute and preparation method thereof

A technology of substitutes and antibiotics, applied in animal feed, animal feed, application, etc., can solve the problems of bacterial flora imbalance, decline of immune function, economic loss of farmers, meat food safety, etc., to increase the amount of meat and eggs, and promote Effects of growth and development, improvement of medicinal efficacy and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

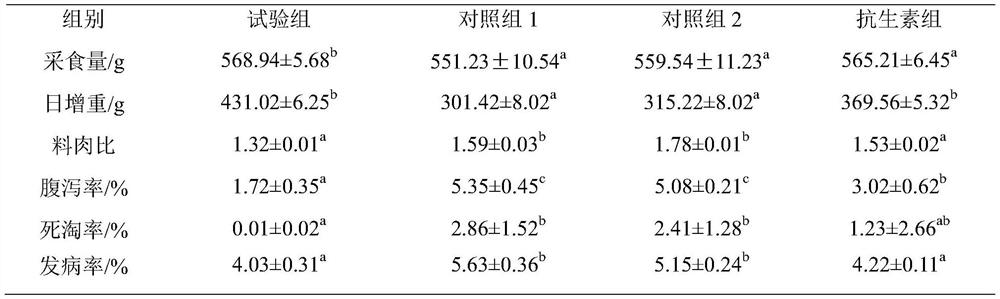

Examples

Embodiment 1

[0037] An antibiotic feed substitute is obtained by fermenting a fermentation base material, a fermentation agent and an enzyme preparation; the fermentation base material includes the following raw materials in parts by mass:

[0038] 10 parts of Radix Isatidis, 10 parts of Shuanghuanglian, 10 parts of Honeysuckle, 15 parts of Huangcen, 10 parts of Forsythia, 200 parts of Houttuynia cordata, 12 parts of soybean meal, 12 parts of corn flour and 15 parts of bran;

[0039] The fermentation agent includes Bacillus subtilis, yeast and lactic acid bacteria, and the Bacillus subtilis, yeast and lactic acid bacteria respectively account for 3%, 2% and 0.5% of the mass of the fermentation bottom material;

[0040] The enzyme preparation is cellulase, which accounts for 3% of the mass of the fermentation bottom material.

[0041] The antibiotic feed substitute in the present embodiment is made through the following steps:

[0042] S1: Mix the fermentation base material with sterile wa...

Embodiment 2

[0047] An antibiotic feed substitute is obtained by fermenting a fermentation base material, a fermentation agent and an enzyme preparation; the fermentation base material includes the following raw materials in parts by mass:

[0048] 8 parts of Radix Isatidis, 15 parts of Shuanghuanglian, 8 parts of Honeysuckle, 16 parts of Huangcen, 9 parts of Forsythia, 220 parts of Houttuynia cordata, 10 parts of soybean meal, 15 parts of corn flour and 15 parts of bran;

[0049] The fermentation agent includes Bacillus subtilis, yeast and lactic acid bacteria, and the Bacillus subtilis, yeast and lactic acid bacteria respectively account for 2%, 3% and 0.4% of the mass of the fermentation bottom material;

[0050] The enzyme preparation is a compound protease, which accounts for 4% of the mass of the fermentation bottom material.

[0051] The antibiotic feed substitute in the present embodiment is made through the following steps:

[0052] S1: mixing the fermentation base material with ...

Embodiment 3

[0057] An antibiotic feed substitute is obtained by fermenting a fermentation base material, a fermentation agent and an enzyme preparation; the fermentation base material includes the following raw materials in parts by mass:

[0058] 12 parts of Radix Isatidis, 5 parts of Shuanghuanglian, 12 parts of Honeysuckle, 12 parts of Huangcen, 12 parts of Forsythia, 180 parts of Houttuynia cordata, 15 parts of soybean meal, 10 parts of corn flour and 20 parts of bran;

[0059] The fermentation agent includes Bacillus subtilis, yeast and lactic acid bacteria, and the Bacillus subtilis, yeast and lactic acid bacteria respectively account for 4%, 1% and 0.8% of the mass of the fermentation bottom material;

[0060] The enzyme preparation is a compound protease, which accounts for 2% of the mass of the fermentation bottom material.

[0061] The antibiotic feed substitute in the present embodiment is made through the following steps:

[0062] S1: mixing the fermentation base material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com