Resource utilization and treatment method for nitromethane waste gas

A technology of nitromethane and resource utilization, which is applied in the field of resource utilization and treatment of nitromethane waste gas. It can solve the problems of reducing nitrogen oxide emissions and purifying harmful waste gas methyl nitrite, so as to reduce emissions and realize green environmental protection. Emissions and the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A kind of purification method of nitromethane tail gas of the present invention, comprises the following steps:

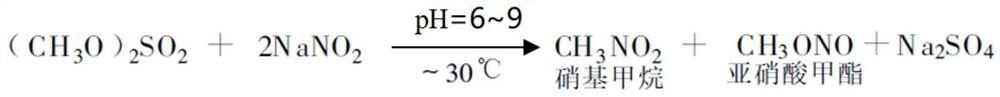

[0097] (1) The nitromethane waste gas produced by the industry through the substitution reaction of dimethyl sulfate and sodium nitrite is washed successively by sodium carbonate solution with pH=9 and sodium hydroxide solution with pH=11, keeping the washing temperature at 0°C;

[0098](2) Pass the tail gas washed by the two-stage lye successively into the absorption solution of absolute ethanol whose molar ratio of sodium hydroxide and hydrazine hydrate is 1.05:1 for reaction and absorption, the temperature of the absorption reaction is 18°C, and the stirring speed is 140r / min, control the pH of the absorbing liquid>9, when the pH=9.3, end the absorption reaction of this batch of absorbing liquid, switch to another absorbing liquid containing hydrazine hydrate and sodium hydroxide absolute ethanol for tail gas absorption, and switch Filter the reaction so...

Embodiment 2

[0100] A kind of purification method of nitromethane tail gas of the present invention, comprises the following steps:

[0101] (1) The nitromethane waste gas produced by industry through the substitution reaction of dimethyl sulfate and sodium nitrite is washed successively by the sodium carbonate solution washing of pH=8.5 and the mixed solution washing of sodium bicarbonate and sodium hydroxide of pH=10, keeping The washing temperature is 45°C;

[0102] (2) Pass the tail gas washed by two-stage lye successively into the absorption solution of anhydrous methanol with a molar ratio of sodium hydroxide and hydrazine hydrate of 1.1:1 for reaction and absorption, the temperature of the absorption reaction is 40°C, and the stirring speed is 120r / min, control the pH of the absorption liquid>9, when the pH=9.35, end the absorption reaction of this batch of absorption liquid, switch to another absorption liquid containing hydrazine hydrate sodium hydroxide anhydrous methanol and th...

Embodiment 3

[0104] (1) the tail gas of the nitromethane produced by industry through the substitution reaction of dimethyl sulfate and sodium nitrite is washed successively by the mixed solution washing of sodium carbonate and sodium hydroxide of pH=9.5 and the washing of sodium hydroxide solution of pH=12, Keep the washing temperature at 20°C;

[0105] (2) Pass the tail gas washed by two-stage lye successively into the absorption solution of anhydrous methanol with a molar ratio of sodium hydroxide and hydrazine hydrate of 1.25:1 for reaction and absorption, the temperature of the absorption reaction is 25°C, and the stirring speed is 80r / min, control the pH of the absorption liquid>9, when pH=9.05, end the absorption reaction of this batch of absorption liquid, switch to another absorption liquid containing hydrazine hydrate sodium hydroxide anhydrous methanol and then carry out tail gas absorption, will switch The obtained reaction solution is filtered, the filtered mother liquor is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com