High-dispersion Co-based bimetallic catalyst based on ZIFs and preparation method thereof

A bimetallic catalyst, highly dispersed technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low metal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of highly dispersed CoNi bimetallic catalyst based on ZIFs specifically comprises the following steps:

[0040] Step 1) 5.357g (297.49g / mol, 18mmol) Zn(NO 3 ) 2 ·6H 2 O and 0.218g (291.03g / mol, 0.75mmol) Co(NO 3 ) 2 ·6H 2 O was dissolved in 150mL of methanol, and a metal salt methanol solution was formed after ultrasonication for 10min; 6.160g (82.1g / mol, 75mmol) of 2-methylimidazole was dissolved in 150mL of methanol, and a 2-methylimidazole methanol solution was formed by ultrasonication for 10min; Quickly pour the salt methanol solution into the 2-methylimidazole methanol solution, sonicate for 10 minutes and place it in a 35°C incubator for 12 hours; then centrifuge the above mixed solution, wash the precipitate with methanol for 3 times, and then place it in a vacuum oven at 60°C Drying in medium for 8h, the ZnCo-ZIFs precursor was obtained.

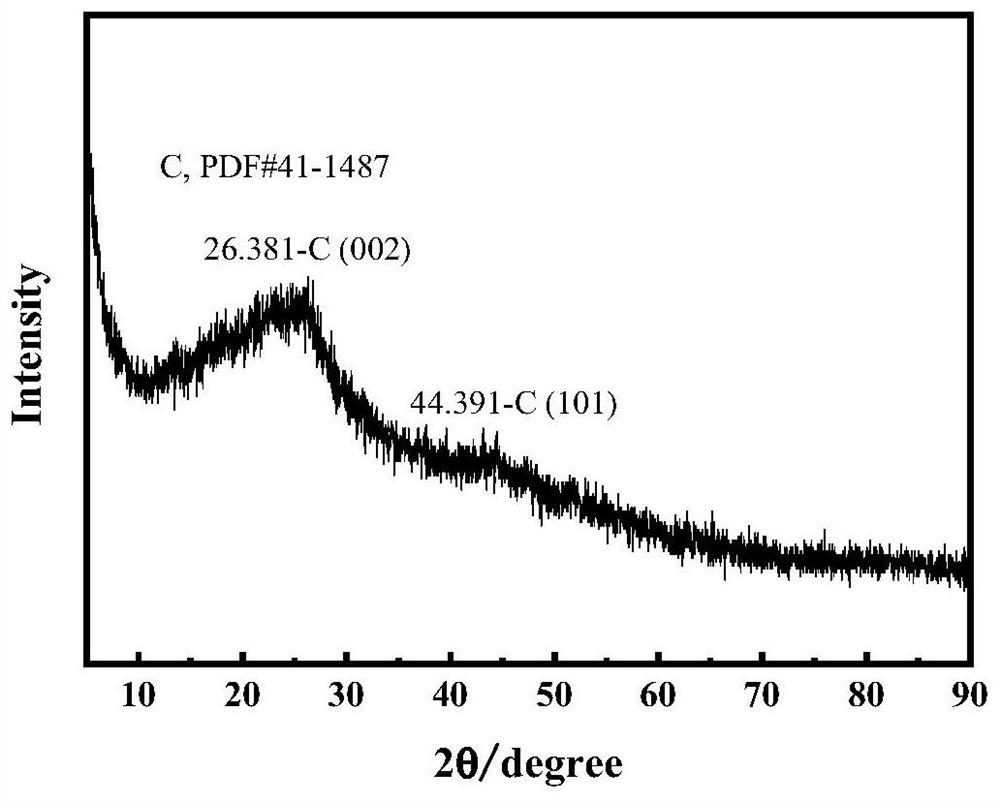

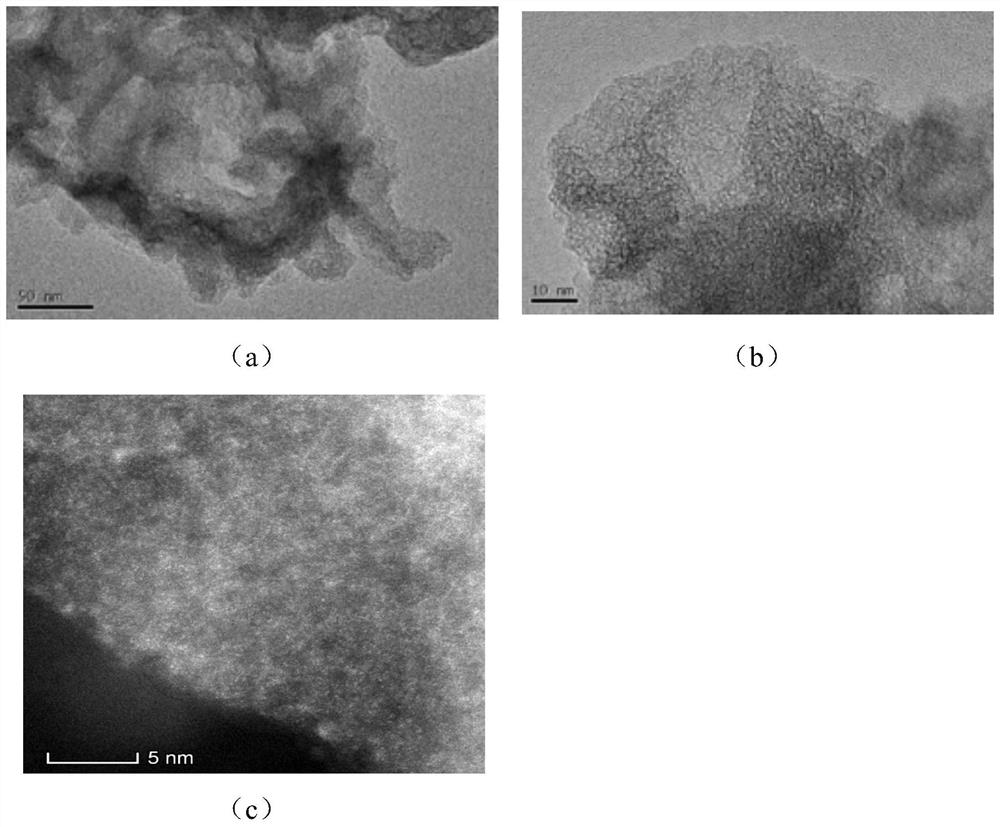

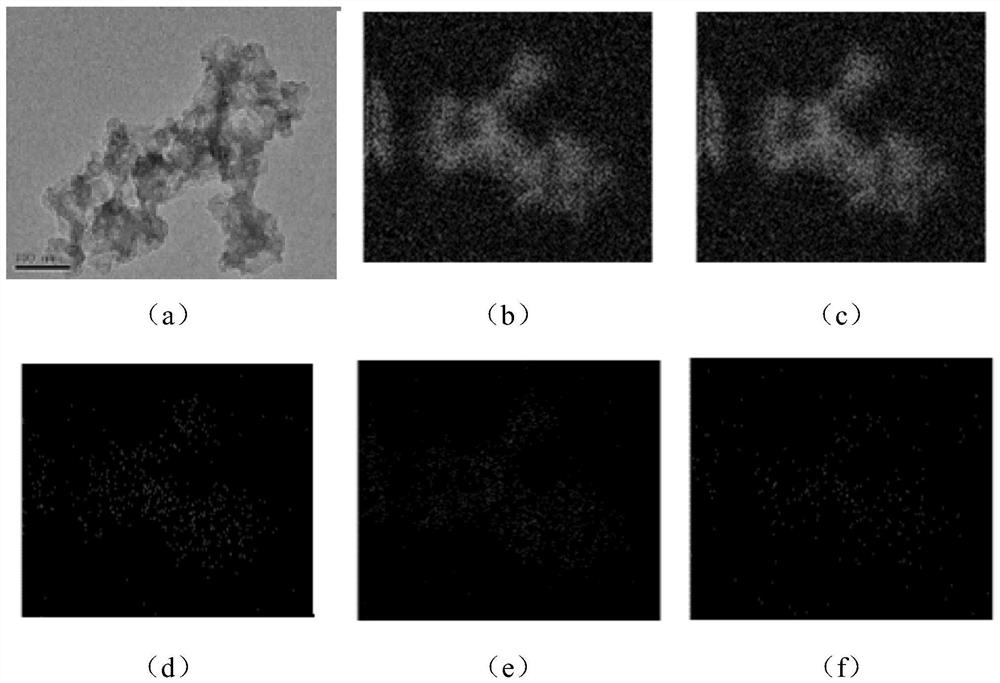

[0041] Step 2) The ZnCo-ZIFs precursor obtained in 1) is subjected to vacuum degassing t...

Embodiment 2

[0049] A highly dispersed CoRh bimetallic catalyst based on ZIFs and a preparation method thereof, specifically comprising the following steps:

[0050] Step 1) 5.357g (297.49g / mol, 18mmol) Zn(NO 3 ) 2 ·6H 2 O and 0.218g (291.03g / mol, 0.75mmol) Co(NO 3 ) 2 ·6H 2 O was dissolved in 150mL of methanol, and a metal salt methanol solution was formed after ultrasonication for 10min; 6.160g (82.1g / mol, 75mmol) of 2-methylimidazole was dissolved in 150mL of methanol, and a 2-methylimidazole methanol solution was formed by ultrasonication for 10min; Quickly pour the salt methanol solution into the 2-methylimidazole methanol solution, put it in a 50°C incubator for 6 hours after ultrasonication for 10min; Drying in medium for 12h, the ZnCo-ZIFs precursor was obtained.

[0051] Step 2) performing vacuum degassing treatment on the ZnCo-ZIFs precursor obtained in step 1) to remove impurities in the precursor. First place the ZnCo-ZIFs precursor in a U-shaped tube, and then install i...

Embodiment 3

[0059] A highly dispersed CoFe bimetallic catalyst based on ZIFs and a preparation method thereof, specifically comprising the following steps:

[0060]Step 1) 7.902g (219.51g / mol, 36mmol) Zn(OAc) 2 2H 2 O and 0.187g (249.08g / mol, 0.75mmol) Co(OAc) 2 4H 2 O was dissolved in 150mL methanol, and a metal salt methanol solution was formed after ultrasonication for 10min; 12.315g (82.1g / mol, 150mmol) 2-methylimidazole was dissolved in 150mL methanol, and ultrasonication was performed for 15min to form a 2-methylimidazole methanol solution; Quickly pour the salt methanol solution into the 2-methylimidazole methanol solution, put it in a 30°C incubator for 12 hours after ultrasonication for 15 minutes; then centrifuge the above mixed solution, wash the precipitate with methanol for 3 times, and then place it in a vacuum oven at 50°C Drying in medium temperature for 10h, the ZnCo-ZIFs precursor was obtained.

[0061] Step 2) The ZnCo-ZIFs precursor obtained in 1) is subjected to v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com