An integrated tobacco logistics storage system

A warehousing system and tobacco technology, applied in the direction of conveyor objects, mechanical conveyors, storage devices, etc., can solve the problems of not particularly large amount of tobacco, low efficiency, high equipment cost, etc., and achieve low equipment cost, high storage accuracy, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

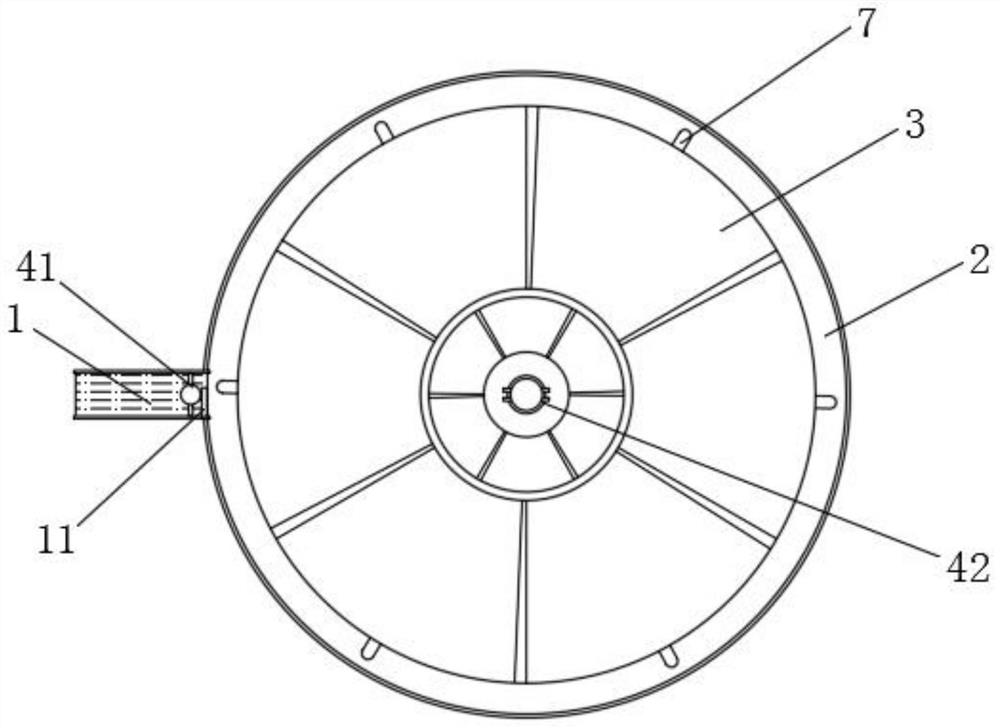

[0035] like figure 1 and Figure 3-6 As shown, an integrated tobacco logistics warehousing system includes:

[0036] Belt conveyor 1; the belt conveyor 1 conveys tobacco with RFID tags;

[0037] The endless conveying disc 2; the endless conveying disc 2 receives the tobacco with the RFID tag conveyed by the belt conveyor 1 and rotates and conveys the tobacco under the driving of the rotating assembly 5, and the belt conveyor 1 passes the rotating assembly 6 Move around the edge of the annular conveying plate 2;

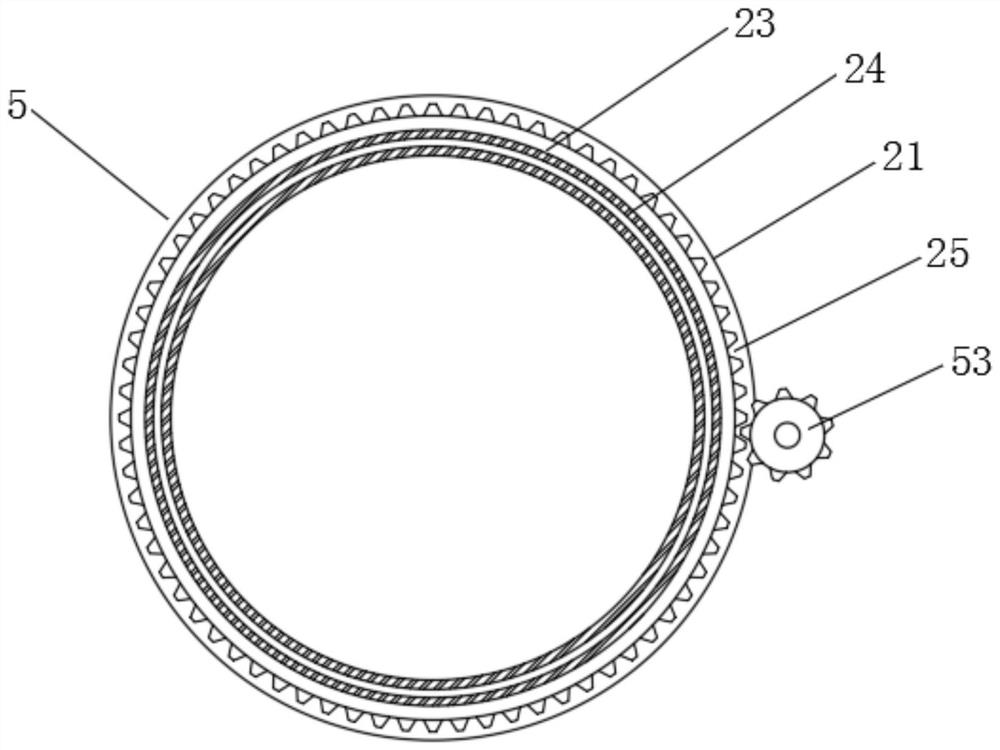

[0038] The annular conveying plate 2 includes an annular plate body 21 , a retaining ring plate 22 , a connecting ring 23 and a bearing 24 . Vertically arranged, the connecting ring 23 is fixedly arranged on the lower surface of the annular disc body 21 and the cross section of the connecting ring 23 is set to be T-shaped. The bottom outer side wall is fixedly connected with the inner ring of the bearing 24 .

[0039] The rotating assembly 5 includes a servo moto...

Embodiment 2

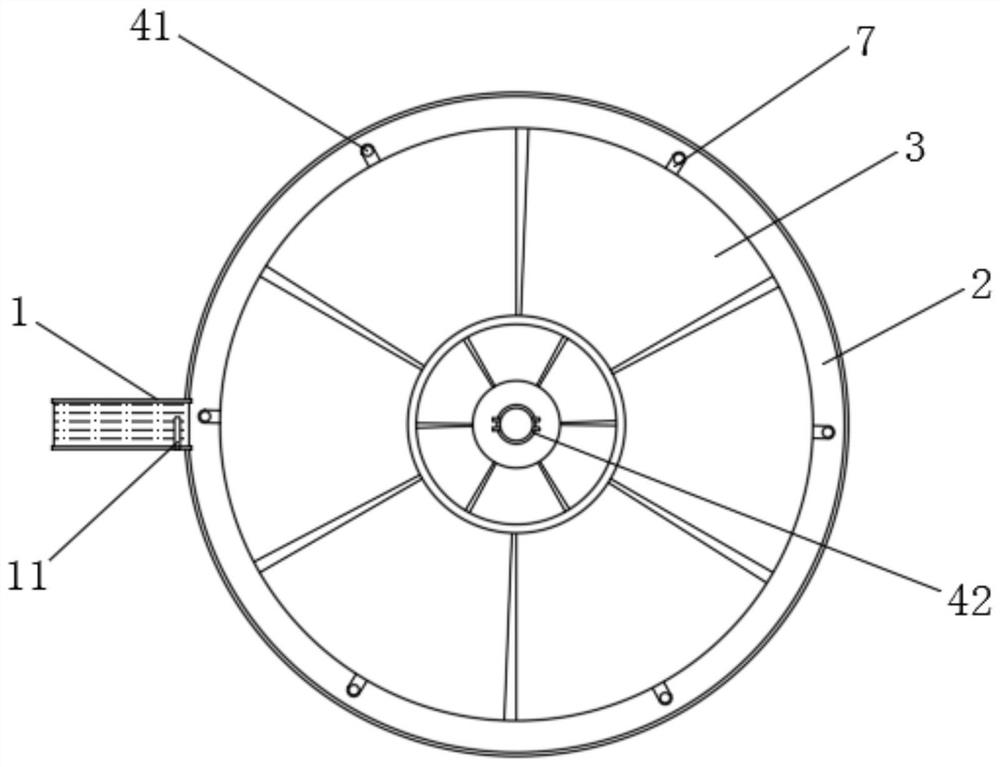

[0056] like figure 2 As shown, the difference from Embodiment 1 is that the RFID identifier 41 in this embodiment is provided at the entrance of each warehouse 3 .

[0057] The belt conveyor 1 conveys the tobacco on the annular conveying plate 2, and the annular conveying plate 2 rotates to convey the tobacco. During the tobacco rotation process, the tobacco is identified by the RFID identifier 41 at the entrance of the warehouse 3, and the RFID identifier 41 scans the tobacco. The RFID tag carried on it, and the identification information is sent to the control unit 42, and the control unit 42 compares the database 421. When the tobacco belongs to the warehouse 3 where the RFID identifier 41 is located, the central controller 422 controls the servo motor 51 to stop. Running, and control the automatic opening and closing of the door to open, control the stacking robot 7 to grab the tobacco and stack it in the warehouse 3, and at the same time display the inventory status thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com